Hydraulic pier protection device

A protection device and bridge pier technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as excessive kinetic energy and bridge pier damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

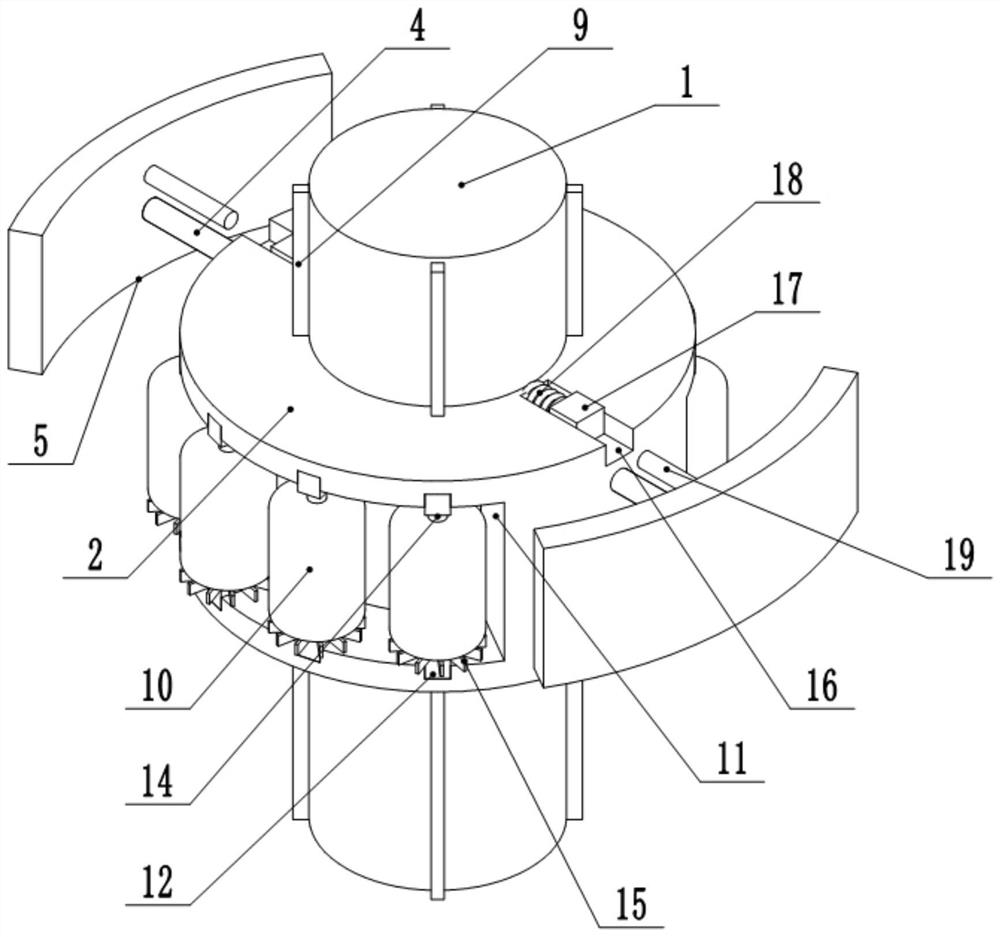

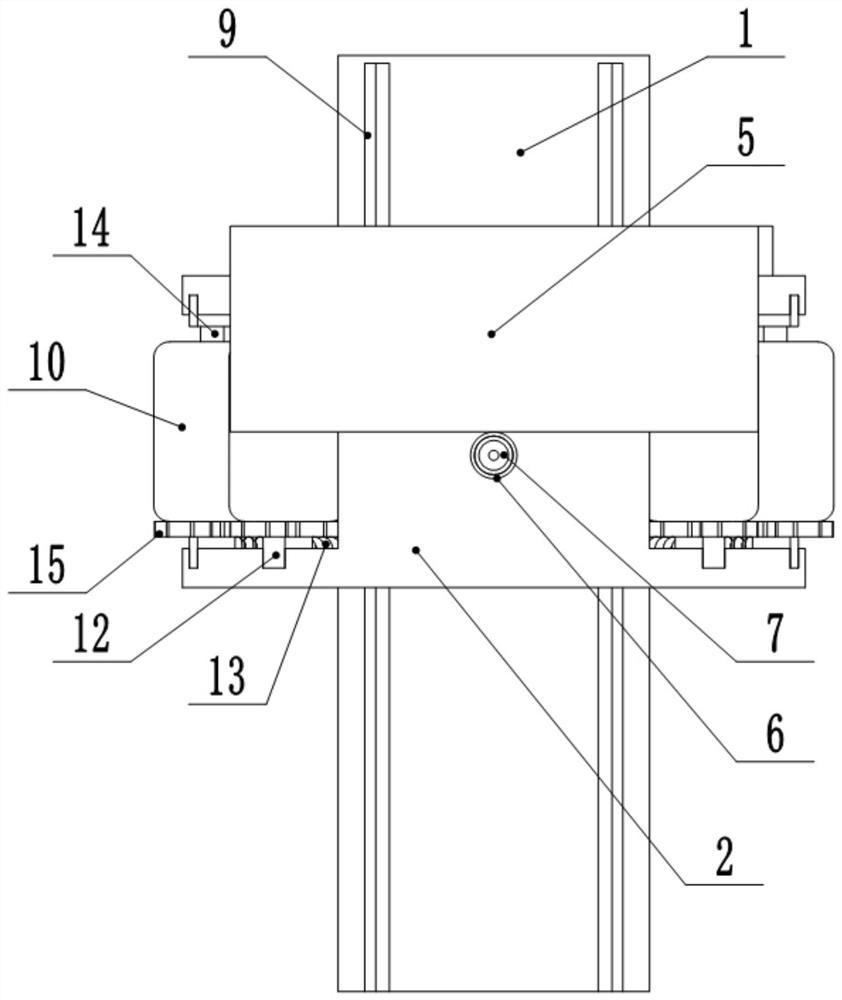

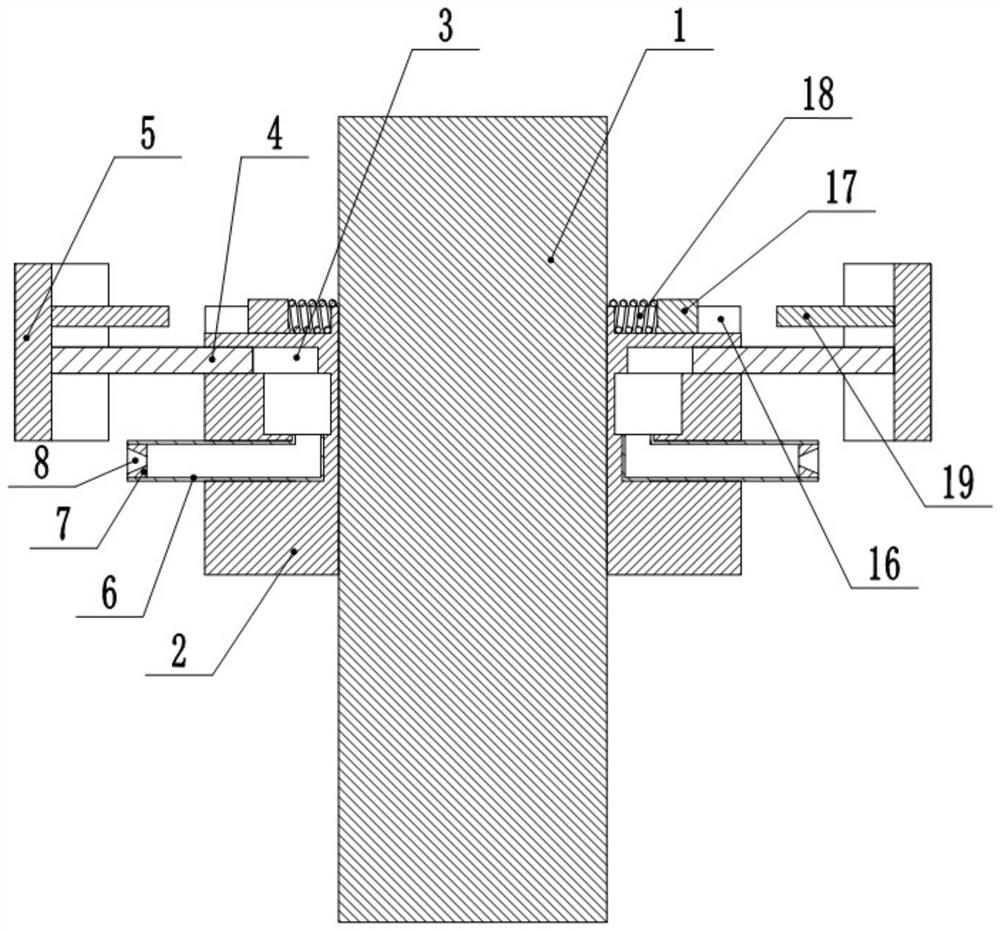

[0022] Such as figure 1 , figure 2 and image 3 Shown: a hydraulic pier protection device, including a pier 1 whose lower end is submerged in the water, a ring-shaped load-bearing platform 2 is set on the pier 1, and several guide columns 9 are fixed around the pier 1, and the guide columns 9 are vertically arranged The inner wall of the load-bearing platform 2 is provided with a number of grooves for accommodating the guide columns 9, and the load-bearing platform 2 is slidably connected to the pier 1 through the guide columns 9; a number of floating rubber cylinders 10 are also fixed on the side walls of the load-bearing platform 2, and the floating rubber cylinders 10 are in the form of Distributed in a circular array, arc-shaped grooves 11 are opened on both side walls of the load-bearing platform 2, and a number of axial chutes are opened at the upper and lower ends of the arc-shaped groove 11, and the chutes are distributed in a circumferential array. Slidingly connec...

specific Embodiment approach

[0023] The floating rubber tube 10 drives the load-bearing platform 2 to float on the water surface as a whole, and cooperates with the cooperation between the guide column 9 and the groove to make the device float with the rise and fall of the water level, and keep the device floating on the water surface to protect the pier 1 at any time.

[0024] When the ship hits the protective plate 5, the protective plate 5 is pushed to slide, and the protective plate 5 drives the pressure rod 4 to slide in the first transverse groove 3, thereby pressurizing the water in the hydraulic chamber and the first transverse groove 3, At this time, the water in the hydraulic chamber and the first horizontal groove 3 has the effect of hydraulic buffering, which consumes energy for the first time on the ship; and the pressurized water is sprayed out through the outlet pipe 6, and the The diameter of the water spray hole 8 is smaller than the diameter of the water outlet pipe 6, and the water is fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com