Small horizontal shaft roller type breeze wind power generation device

A wind power generation, roller type technology, applied in the field of small horizontal axis roller type breeze wind power generation device, can solve the problems of small wind passing area, small rotating torque, motor accident damage, etc., to expand the windward area and reduce the negative pressure value , The effect of increasing the wind pressure value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

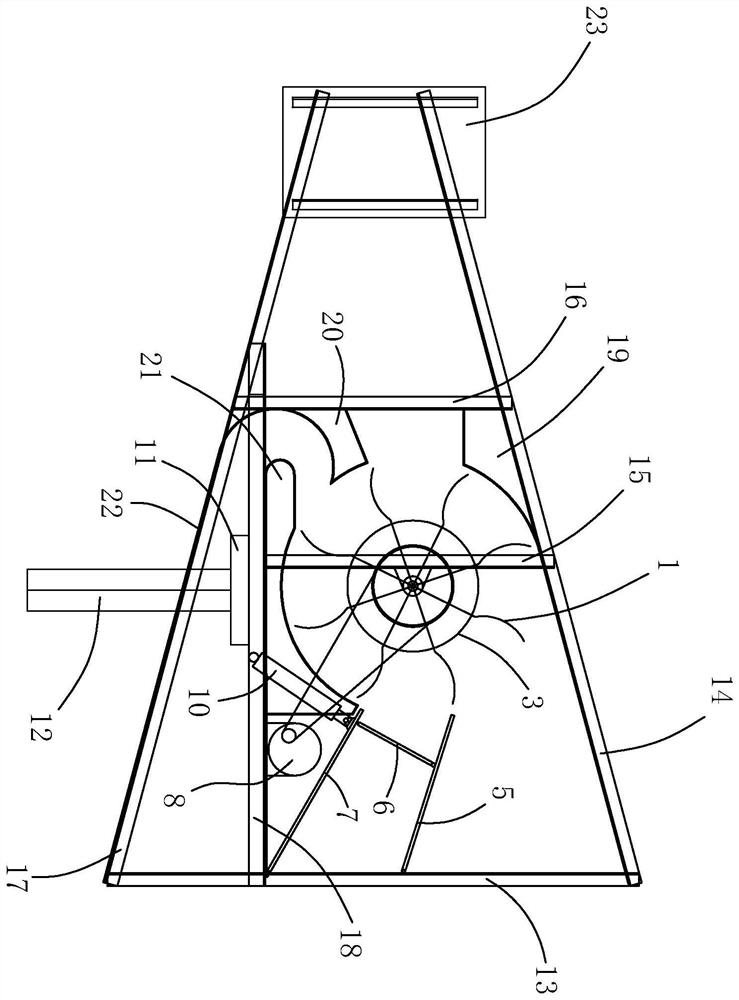

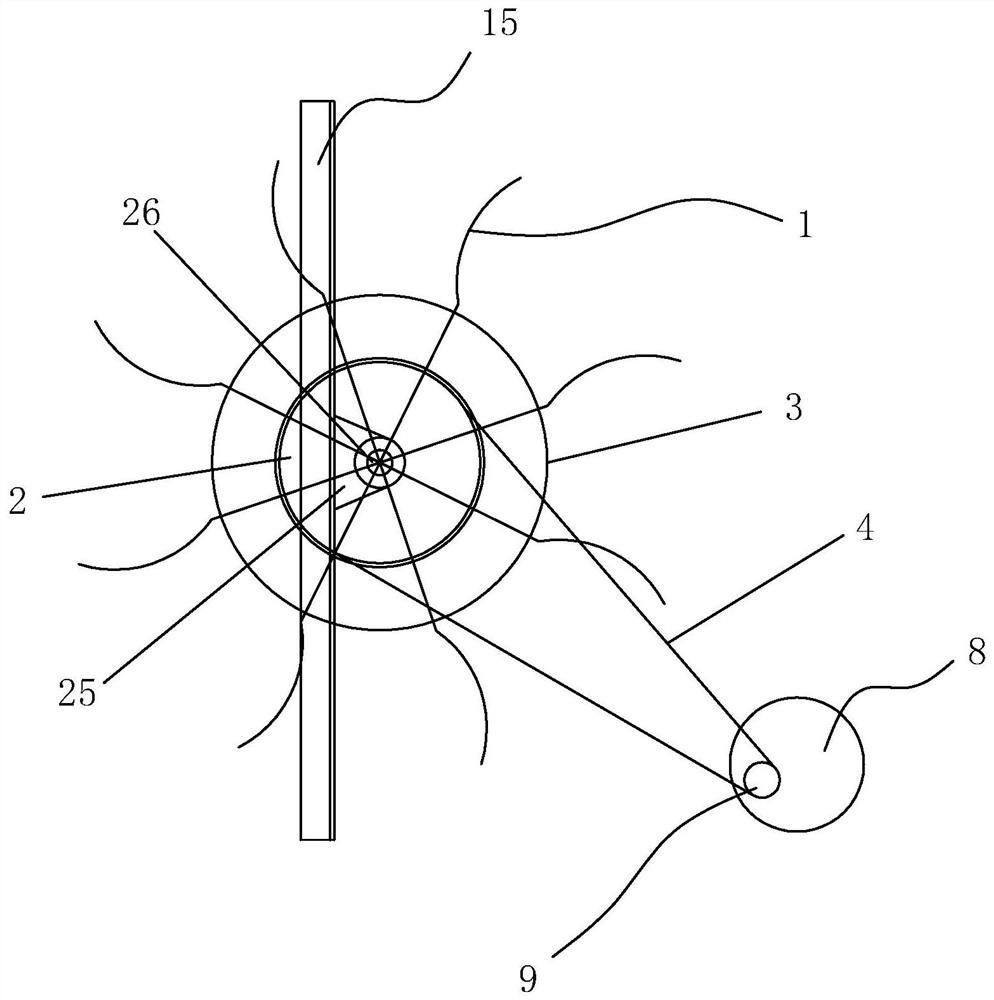

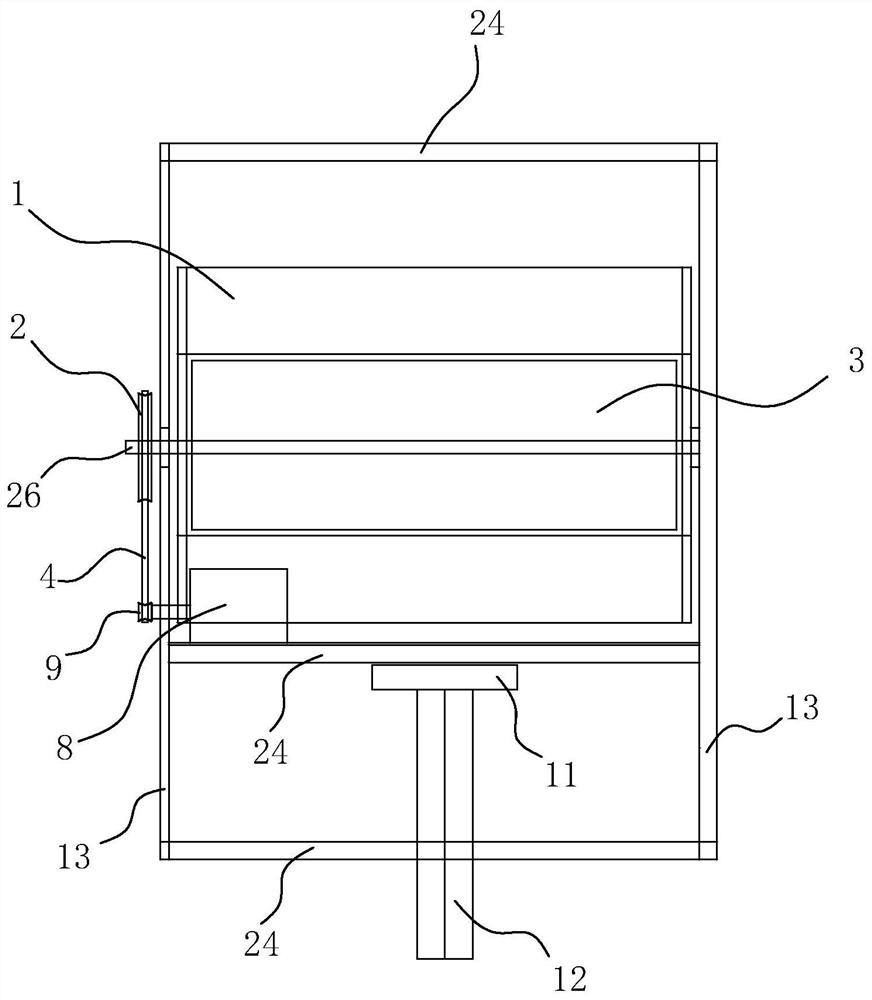

[0051] Combine Figure 1 to Figure 8 , This embodiment will be described in detail. This embodiment relates to a small horizontal axis roller type breeze wind energy power generation device, including a quadrangular cone structure air guide tube, and a horizontal roller blade wheel arranged inside the air guide tube, the roller blade wheel passes The transmission device is connected to a small permanent magnet DC generator 8. See details figure 1 .

[0052] In this embodiment, the air guide tube is designed as a quadrangular cone, and compared to the existing wind power generation device, the windward surface has been greatly enlarged. Coupled with the conical design of the air duct, it has the effect of compressing the wind, greatly increasing the wind pressure value and increasing the wind speed.

[0053] And the use of horizontal roller blade wheel overcomes the shortcomings of the current technology of small and medium-sized horizontal axis blade type wind turbines. Althoug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com