Crank connecting rod type electromechanical inerter device

A crank-link mechanism and crank-link technology, which is applied in electromechanical devices, inertial effect dampers, electrical components, etc., can solve the problem that the working performance of the inerter cannot be guaranteed, the gear teeth or the screw are broken, and the insulation of the inerter is affected. Vibration performance and other issues, to achieve the effect of rich variety, stable performance and simple mode of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

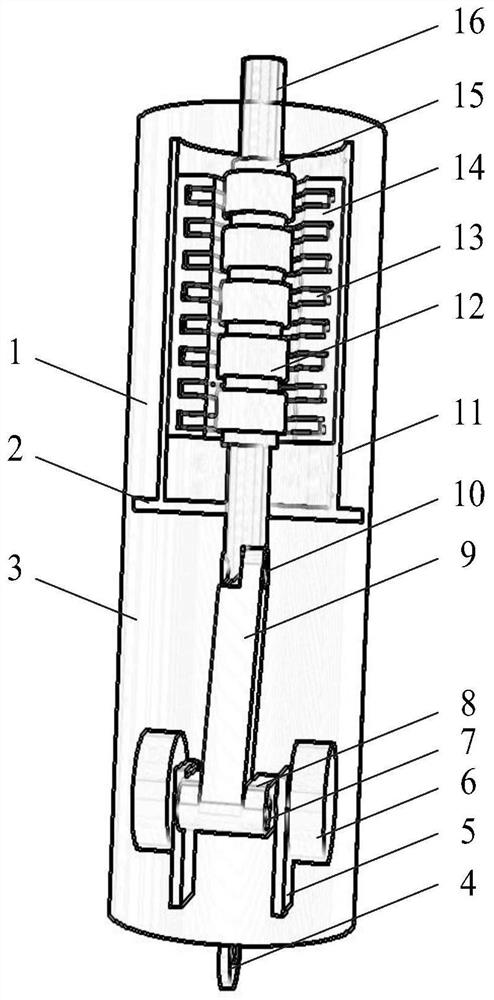

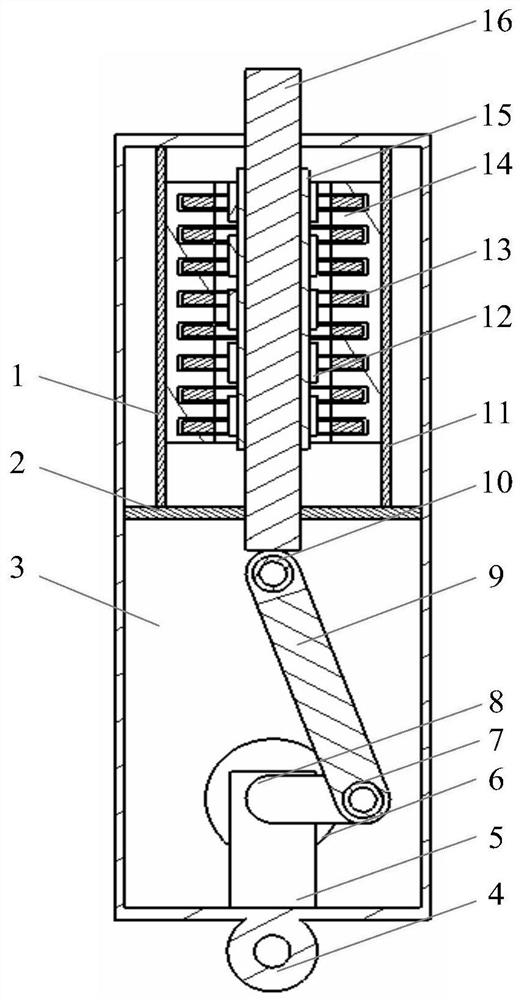

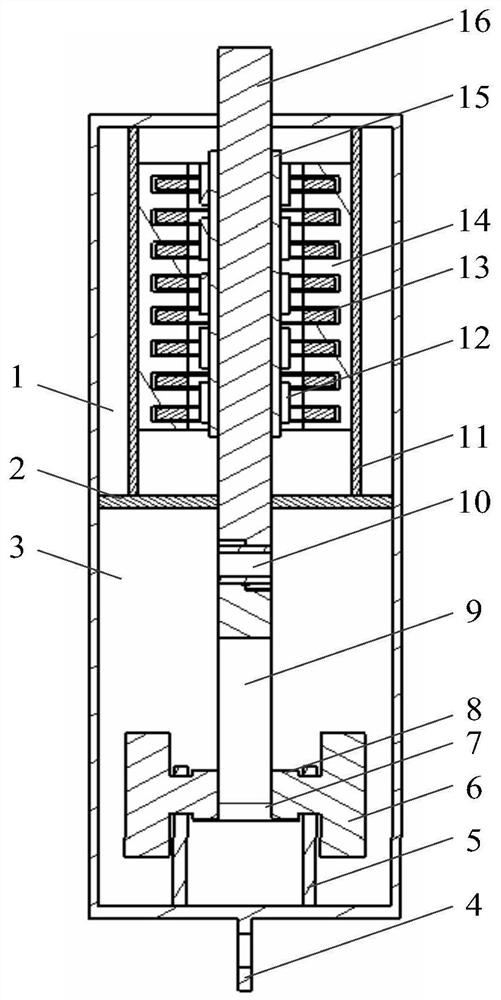

[0041] Such as Figure 1-3 As shown, the present invention relates to a crank-link type electromechanical inerter device, comprising: a linear motor working chamber 1, an intermediate partition plate 2, an inerter working chamber 3, a cylinder 4, a crank shaft seat 5, a flywheel 6, and a crank pin 7. Crank 8, connecting rod 9, connecting rod pin 10, motor barrel 11, magnetic pole 12, winding coil 13, stator core 14, mover yoke 15, motor shaft 16.

[0042] Wherein, the cylinder barrel 4 is divided into a linear motor working chamber 1 and an inerter working chamber 3 by an intermediate partition 2 . A cylindrical linear motor is installed in the working chamber 1 of the linear motor, which is composed of a motor barrel 11 , magnetic poles 12 , winding coils 13 , stator co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com