Floating pipe construction device for penetrating functional pipeline in long-distance sleeve and construction method thereof

A construction device and construction method technology, applied in the direction of pipes/pipe joints/fittings, pipe supports, mechanical equipment, etc., can solve the process restrictions of functional pipeline transportation, connection and installation, cannot carry out flow operation, and functional pipeline distance Long and other problems, to achieve the effect of small volume of excavation work in the early stage, small space occupation, and simplified difficulty of pipe penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

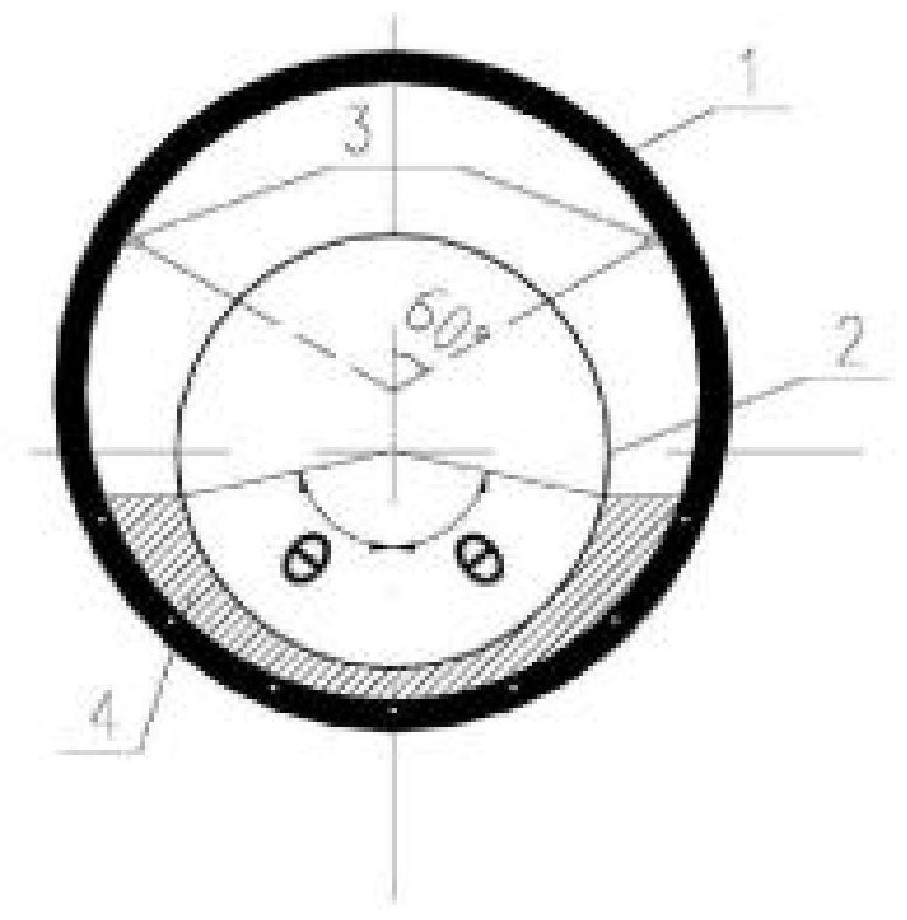

[0030] Based on the above-mentioned device and construction method, it is applied in specific embodiments. The DN1500mm reinforced concrete pipe is used as the outer casing, and the DN800mm water supply plastic-coated composite steel pipe is used as the functional pipe to carry out the pipe penetration operation.

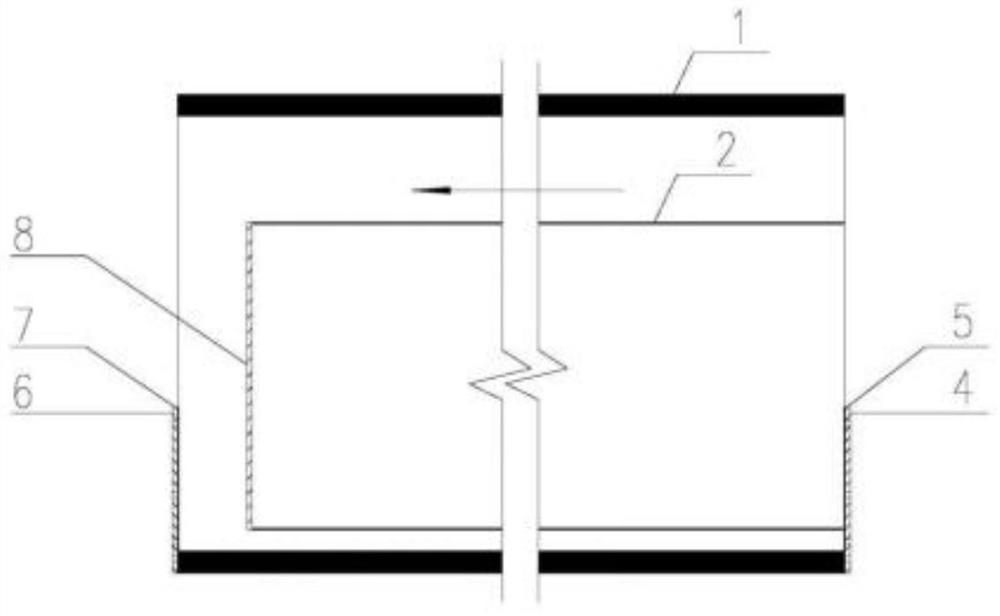

[0031] The floating pipe construction device with a functional pipeline inside the long-distance casing includes a functional pipeline 2 and an outer casing 1, wherein the two ends of the outer casing are respectively set as an inlet end and an outlet end, and the positions of the inlet end and the outlet end are respectively along A front baffle plate 4 and a rear baffle plate 6 are installed in the radial direction, and a sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com