Double-sound-beam lute

A sound beam and pipa technology, applied in the field of traditional Chinese plucked string instruments, can solve the problem that the pipa resonance box cannot take into account the good resonance timbre and penetration in the high, middle and low ranges, so as to improve the timbre and penetration and strengthen the strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

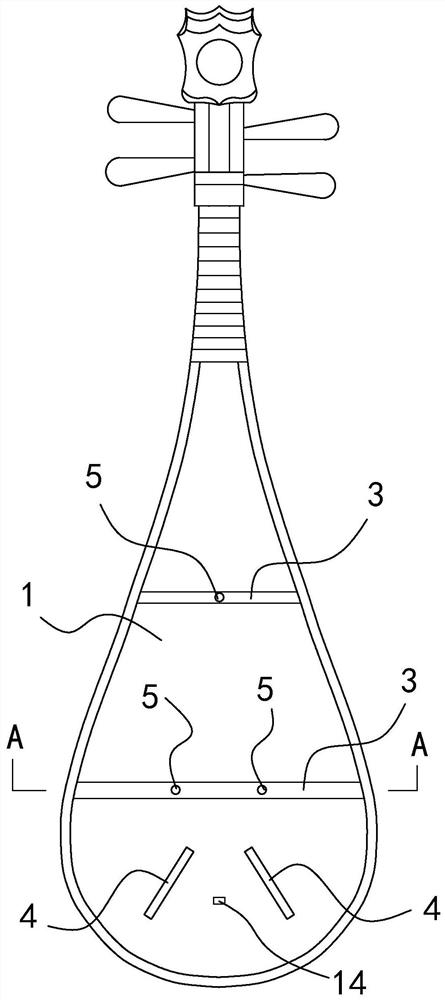

[0053] Embodiment 1: A double-sound beam pipa (single-sided double-sound beam structure)

[0054] Because the innovations of the present invention are all concentrated on the resonance box, so this embodiment will focus on describing the structure and structure of the pipa resonance box, and other structures about the pipa can be considered to be realized by the prior art, and will not be described in this embodiment. Details.

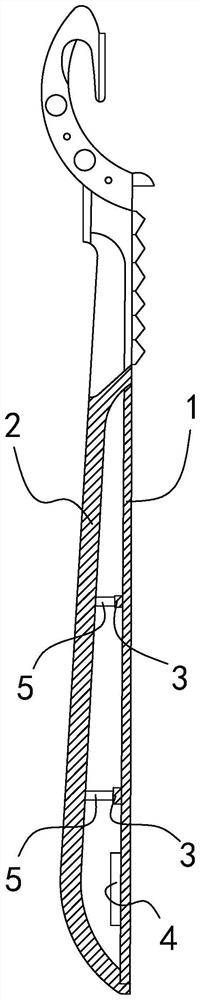

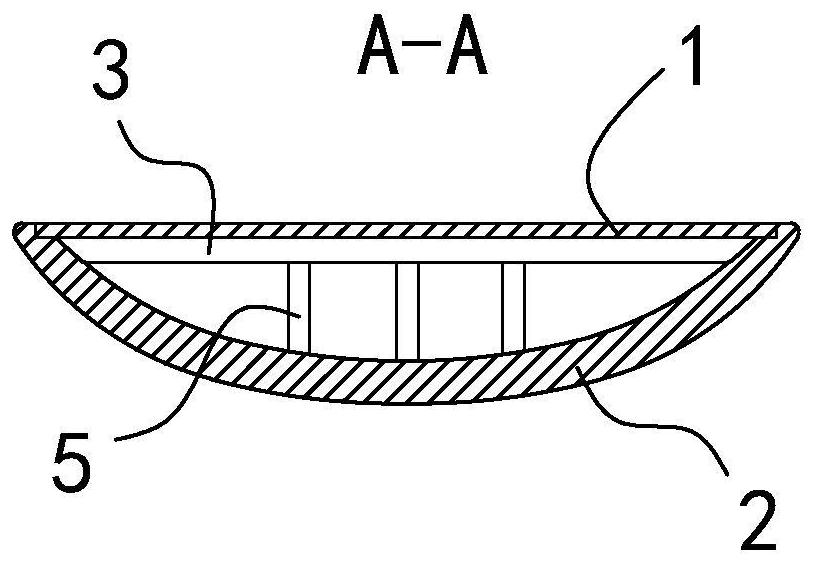

[0055] The structure and structure of the pipa resonance box of the present embodiment: as Figure 4-Figure 8 , Figure 14 , Figure 15 , Figure 18-Figure 21 As shown, the box body of the resonance box is composed of panel 1 and bottom plate 2 (see Figure 5-Figure 8 ).

[0056] In the resonance box, two upper sound beams 6 (see Figure 4 with Image 6 ), the upper sound bracing 6 is a strip-shaped sound bracing member (see Figure 14 with Figure 15 ), one side of the two upper sound beams 6 is closely fixed on the inner wall of the panel 1,...

Embodiment 2

[0061] Embodiment 2: A double-sound beam pipa (double-sided double-sound beam structure)

[0062] The difference between embodiment 2 and embodiment 1 is: the base plate 2 of embodiment 1 is a thick plate, and the inner wall of base plate 2 is not provided with double sound beams and groove structures, while the base plate of embodiment 2 is a thin plate, and the base plate The inner wall of 2 is provided with double sound beam and groove structure. The specific content is as follows:

[0063] Such as Figure 9-Figure 13 , Figure 16 , Figure 17 , as shown, two lower sound beams 7 are arranged in the resonance box (see Figure 10 with Figure 11 ), the lower sound bracing 7 is a strip-shaped sound bracing member (see Figure 16 with Figure 17 ), one side of the two lower sound beams 7 is closely fixed on the inner wall of the bottom plate 2, and the other side of the two lower sound beams 7 is suspended in the resonance box relative to the panel 1 (see Figure 11 ), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com