Anti-drop plug and socket based on thermal expansion principle

A kind of anti-detachment and thermal expansion technology, which can be applied to the parts of the connecting device, the two-part connecting device, electrical components, etc., and can solve the problem of the plug easily falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

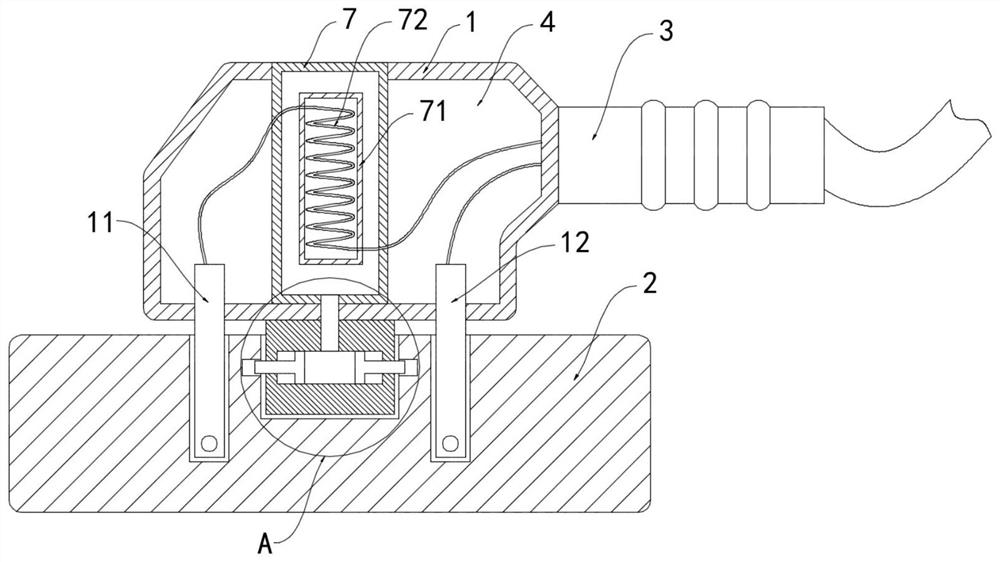

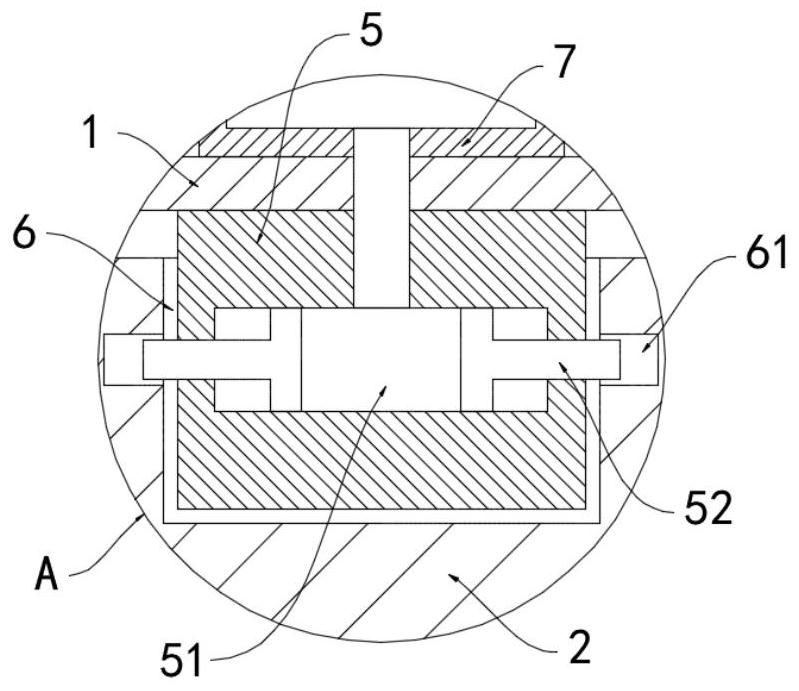

[0022] Such as Figure 1-2 As shown in the figure, an anti-off plug and socket based on the principle of thermal expansion includes a plug 1, a socket 2, a plug-in piece and an external wire 3 installed in the plug 1, a cavity 4 is provided in the plug 1, and the bottom of the plug 1 A clamping block 5 is fixedly connected, and the upper surface of the socket 2 is provided with a card slot 6 matching the clamping block 5;

[0023] The cavity 4 is provided with a transparent housing 7 filled with a mixture of nitrogen dioxide and dinitrogen tetroxide. The inner wall of the transparent housing 7 is fixedly connected with a heating tube 71, and the heating tube 71 is provided with a The heating wire 72 and the upper end of the transparent casing 7 are set through the top surface of the cavity 4. When the appliance is in use, the balance of the mixed gas of nitrogen dioxide and dinitrogen tetroxide moves to the direction of nitrogen dioxide generation, because the two Nitrogen ox...

Embodiment 2

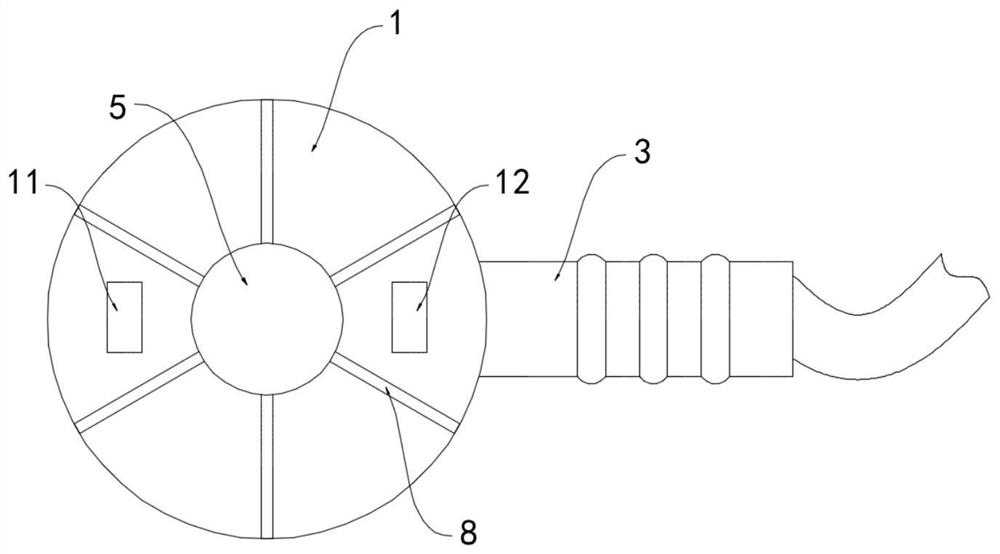

[0031] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the bottom of the plug 1 is fixedly connected with multiple water-absorbing expansion strips 8, and the multiple water-absorbing expansion strips 8 all extend from the center of the bottom surface of the plug 1 to form an annular array. arranged.

[0032] In this embodiment, a plurality of water-absorbing expansion strips 8 divide the contact surface between the plug 1 and the socket 2 into a plurality of mutually isolated sections, and the live line plug-in piece 11 and the neutral line plug-in piece 12 are located in different sections to prevent the socket from 2. When there is water stain on the surface, the water directly conducts the circuit between the live line plug-in piece 11 and the neutral line plug-in piece 12, and the risk of short circuit occurs, and when there is water stain on the surface of the socket 2, the water-absorbing expansion strip 8 can remove the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com