Comprehensive regeneration and reuse process based on casting waste molding sand

A waste molding sand and process technology, applied in the direction of casting molding equipment, manufacturing tools, cleaning/processing machinery of casting materials, etc., can solve the problems of waste molding sand recycling and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a comprehensive recycling process based on foundry waste sand, which specifically includes the following steps:

[0028] S1. Collect the waste casting sand, and absorb and collect the dust in the waste casting sand through the air blowing equipment during the collection process;

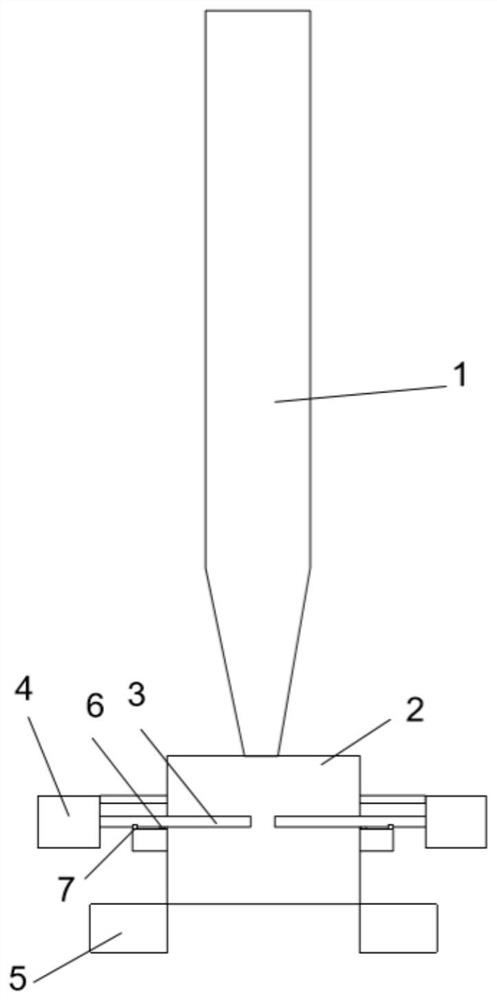

[0029] S2. Cut and pulverize the waste foundry sand processed in step S1, convey the cut and crushed waste foundry sand through the cyclone separator after the crush treatment, and collect the metal in the waste foundry sand through the magnetic core in the cyclone separator 1 Residue, so as to realize the separation effect on separating the metal residue and the old molding sand mixture; then the metal residue obtained by separation is sent to step S6, and the old molding sand obtained by separation is sent to step S3;

[0030] S3, spraying the old molding sand processed in step S2, and collecting the dust in the conveying process after spraying;

[0031] S4, then bu...

Embodiment 2

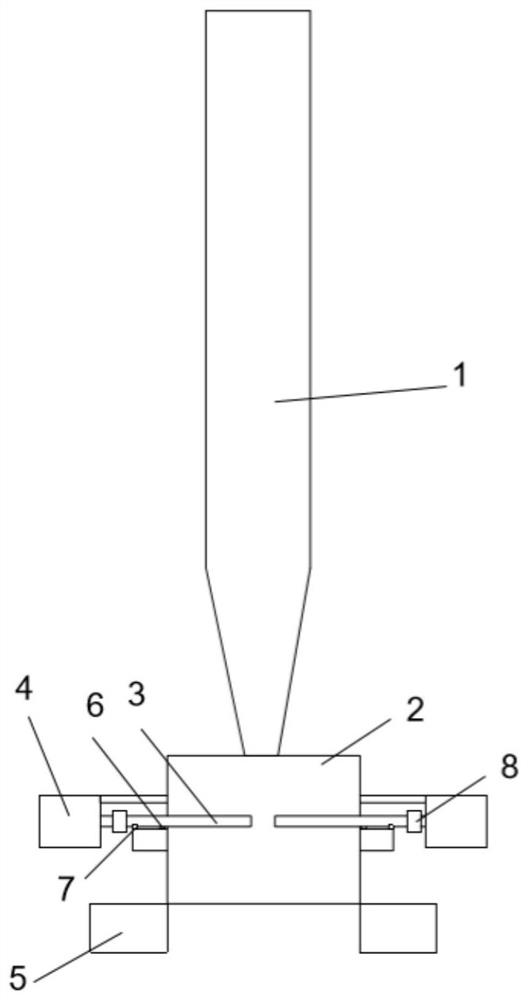

[0044] Such as figure 2 As shown, the process of this embodiment is the same as that of Embodiment 1, the difference is that in order to improve the rapid collection of metals, a rotating motor that drives the magnetic core rod 3 to rotate is provided between the magnetic core rod 3 and the first cylinder 4 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com