Technology for producing electric-controlled valve

An electric control valve and production process technology, applied in valve details, valve device, valve shell structure, etc., can solve problems such as many contact points, unfavorable valve stem cleaning, valve stem processing effects, etc., to avoid jitter and improve transportation stability. Sex, the effect of increasing the fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

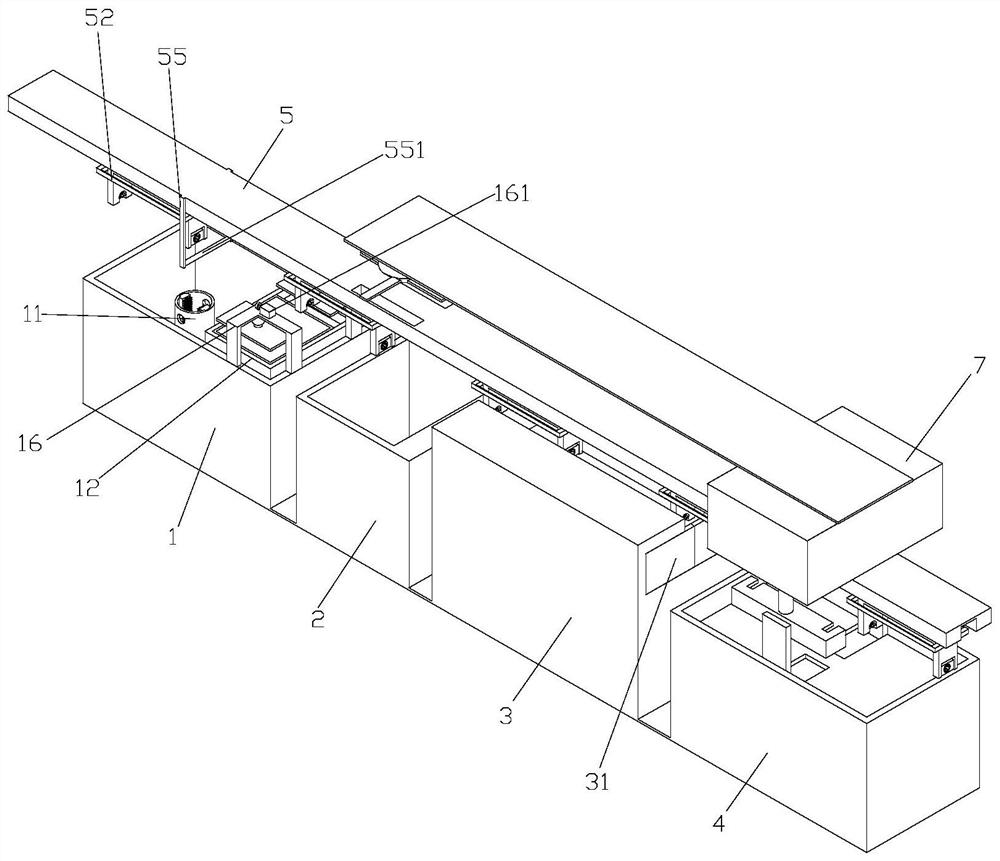

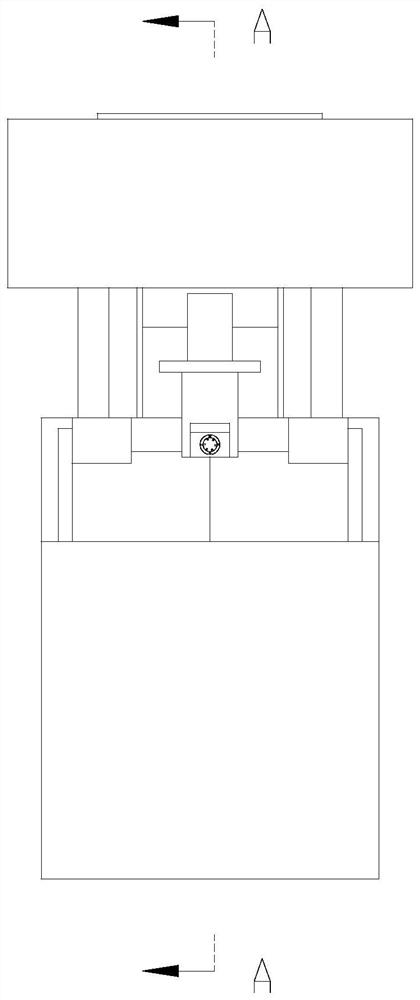

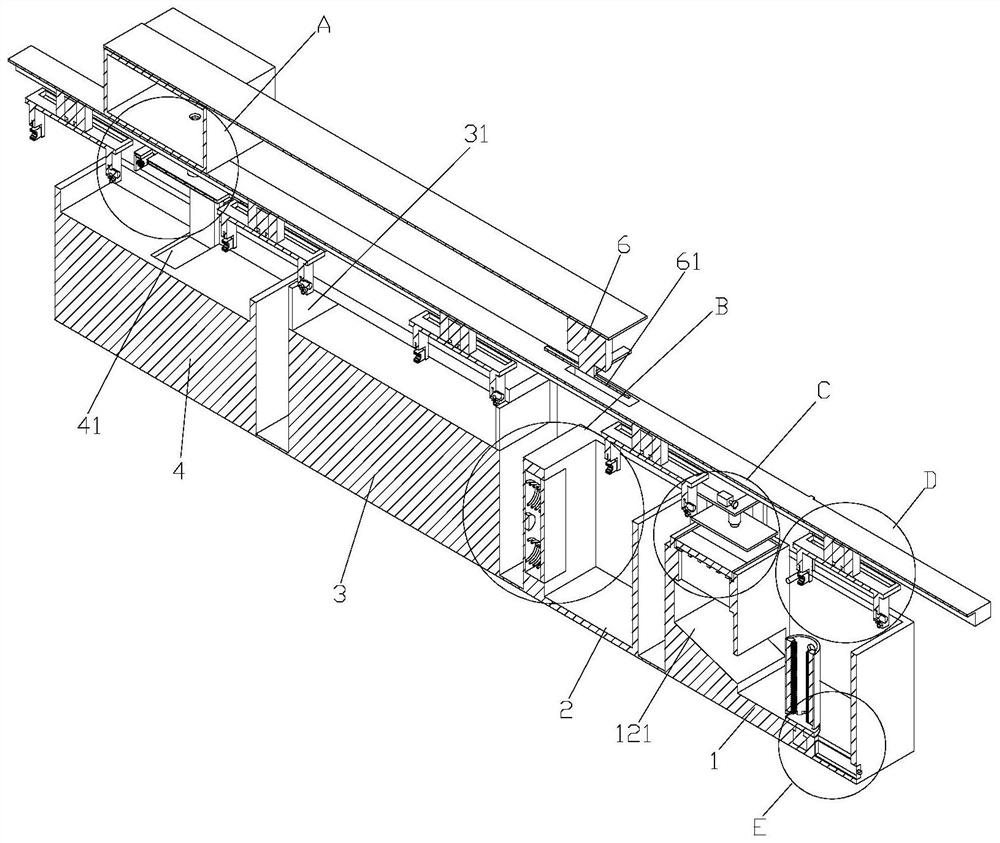

Image

Examples

Embodiment Construction

[0044] A production process of an electric control valve, including a, valve body manufacturing: purchasing castings, performing surfacing welding after testing the castings, and then performing post-welding heat treatment on the castings, grinding the sealing surface of the valve body; b, valve disc, valve seat Manufacturing: Purchasing raw materials, making blanks after testing raw materials, performing ultrasonic flaw detection and surfacing welding operations on blanks, grinding the sealing surface, and doing hardness testing on sealing surfaces; c. Valve stem manufacturing: purchasing raw materials, making blanks after raw material inspection, Surfacing and heat treatment after surfacing, finishing each part, putting the valve stem into the surface treatment system for surface treatment; d, internal parts manufacturing: purchase raw materials, conduct incoming inspection on raw materials, and make rough rough machining ultrasonic flaw detection surface, Finishing each depa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com