Production method of water-cooled strand with intelligent monitoring

A production method and technology of intelligent monitoring, applied in the field of water-cooled strand production, can solve the problems of reducing work efficiency, reducing usage rate, strand introduction, etc., and achieving the effects of improving production and processing efficiency, improving production efficiency, and good buffering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

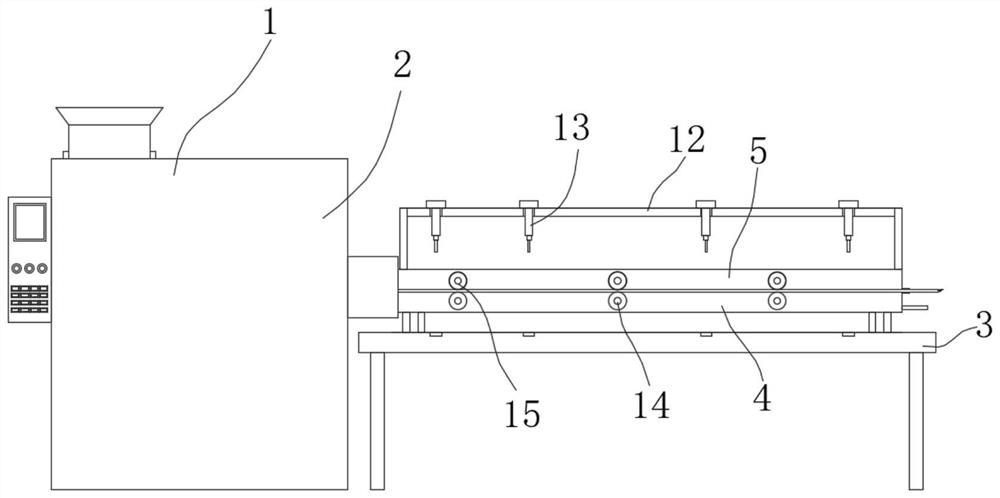

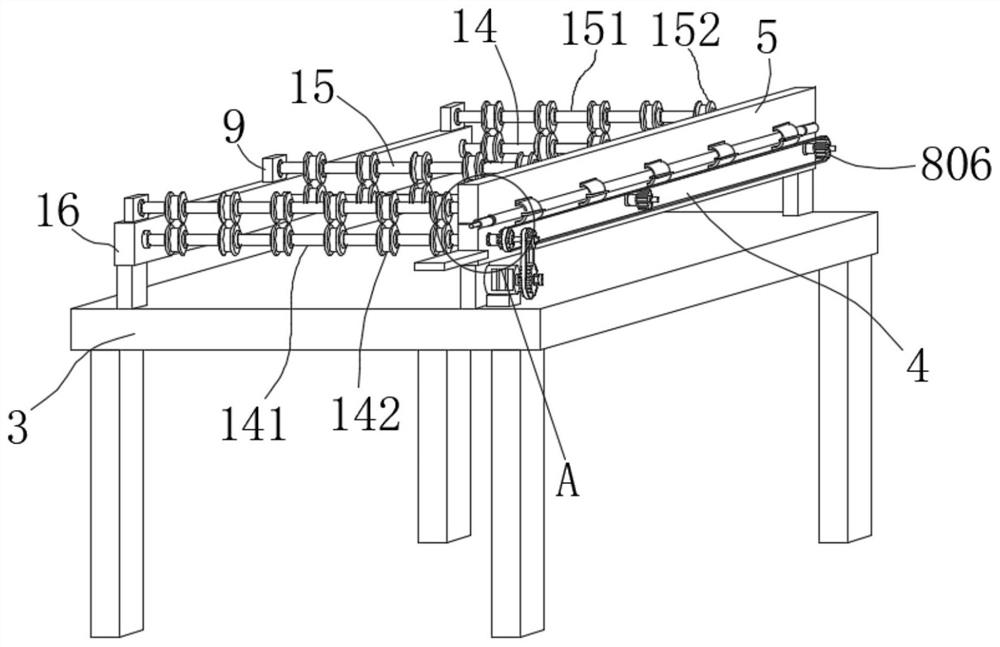

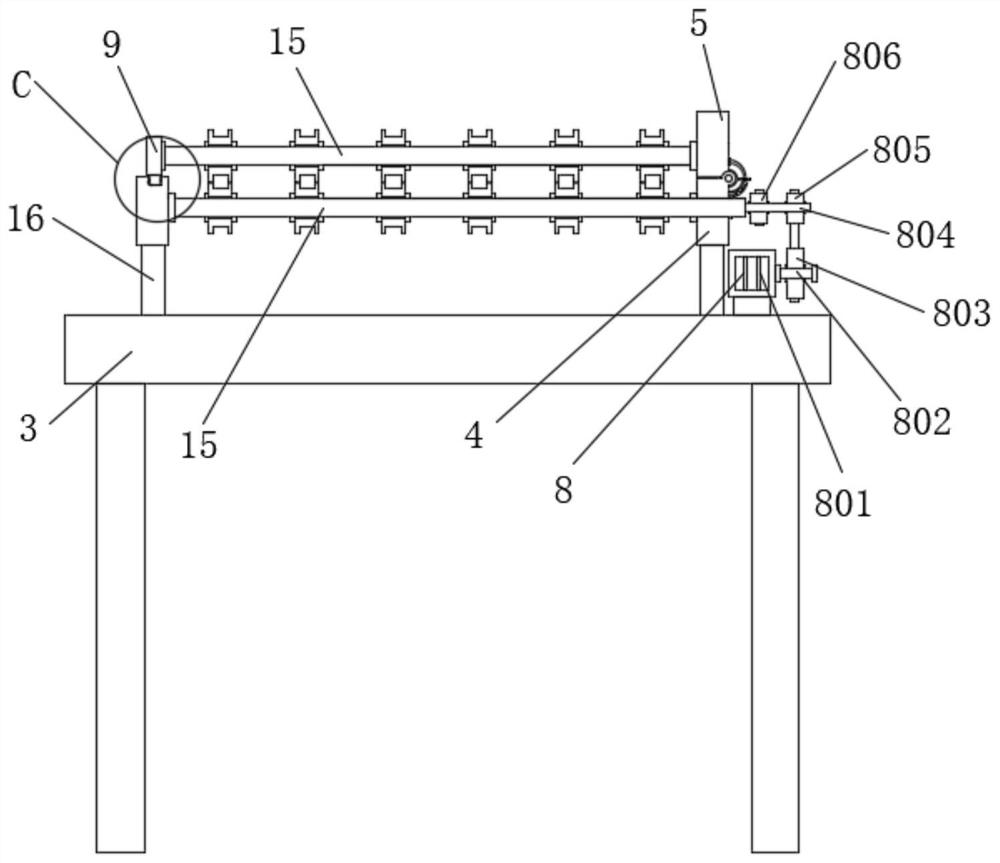

[0035]Example 1: A water-cooled strand production method with intelligent monitoring, based on a production device, the production device includes a device main body 1, an extrusion box 2 connected to one side of the device main body 1, and an extrusion box 2 disposed opposite to each other. a support frame 3 on one side of the device main body 1;

[0036] One end of the upper surface of the support frame 3 is provided with a first fixing plate 4 , and the other end of the upper surface of the supporting frame 3 is provided with a second fixing plate 16 opposite to the first fixing plate 4 . 4 and the second fixed plate 16 are provided with a number of first guide rollers 14, one end of each of the first guide rollers 14 is rotatably connected to the second fixed plate 16, and the other end passes through the first fixed plate 4 It is rotatably connected with the first fixing plate 4. A connecting shaft 804 is provided on one end of the first guide roller 14 passing through th...

Embodiment 2

[0049] Example 2: A water-cooled strand production method with intelligent monitoring, based on a production device, the production device includes a device main body 1, an extrusion box 2 connected to one side of the device main body 1, and an extrusion box 2 disposed opposite to the other. a support frame 3 on one side of the device main body 1;

[0050] One end of the upper surface of the support frame 3 is provided with a first fixing plate 4 , and the other end of the upper surface of the supporting frame 3 is provided with a second fixing plate 16 opposite to the first fixing plate 4 . 4 and the second fixed plate 16 are provided with a number of first guide rollers 14, one end of each of the first guide rollers 14 is rotatably connected to the second fixed plate 16, and the other end passes through the first fixed plate 4 It is rotatably connected with the first fixing plate 4. A connecting shaft 804 is provided on one end of the first guide roller 14 passing through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com