Cap opening device for ampoule bottles

A cap-opening device and ampoules technology, which is applied to bottle/container caps, electric operation devices, manual cutting devices, etc., can solve the problems of labor-intensive and low work efficiency, and achieve the advantages of improving work efficiency, simple operation and manpower saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

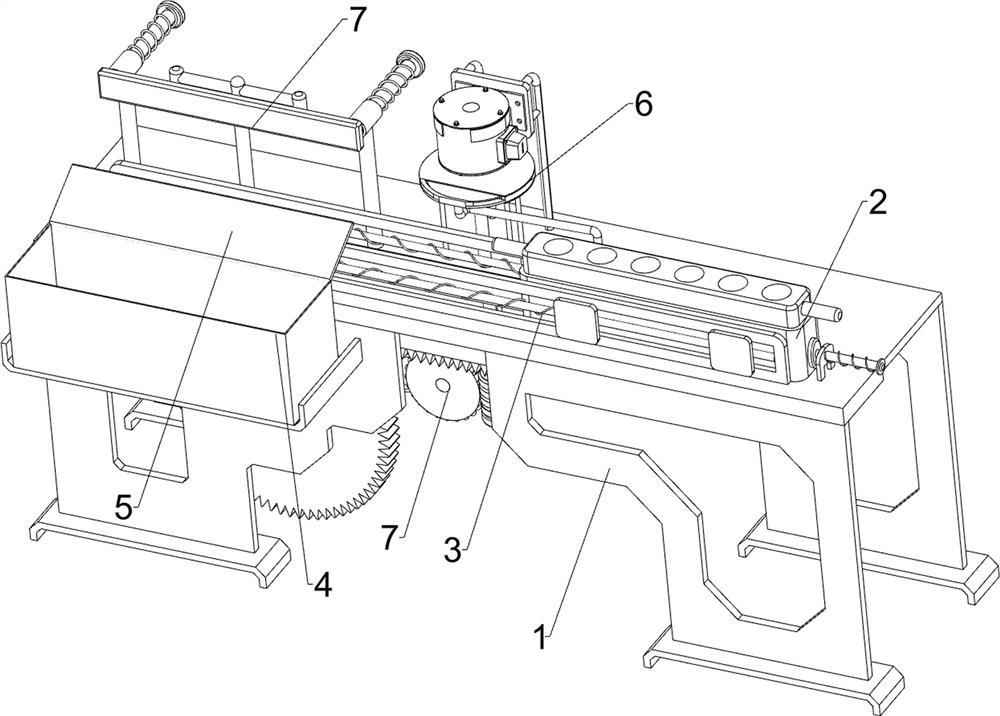

[0024] An ampoule bottle cap opening device, such as Figure 1-2 and Figure 4 As shown, it includes an installation table 1, a sliding frame 2, a first return spring 3, a collection frame 4 and a swash plate 5. The top of the installation table 1 is slidably connected with a sliding frame 2, and there is a certain distance between the sliding frame 2 and the installation table 1. A first return spring 3 is connected between the sliding frame 2 and the installation table 1, a collection frame 4 is connected to the left side of the installation table 1, a sloping plate 5 is connected to the top of the collection frame 4, and a movable cutting assembly 6 and For the pusher assembly 7 , a movable cutting assembly 6 is arranged between the installation table 1 and the sliding frame 2 , and a pusher assembly 7 is arranged on the installation table 1 .

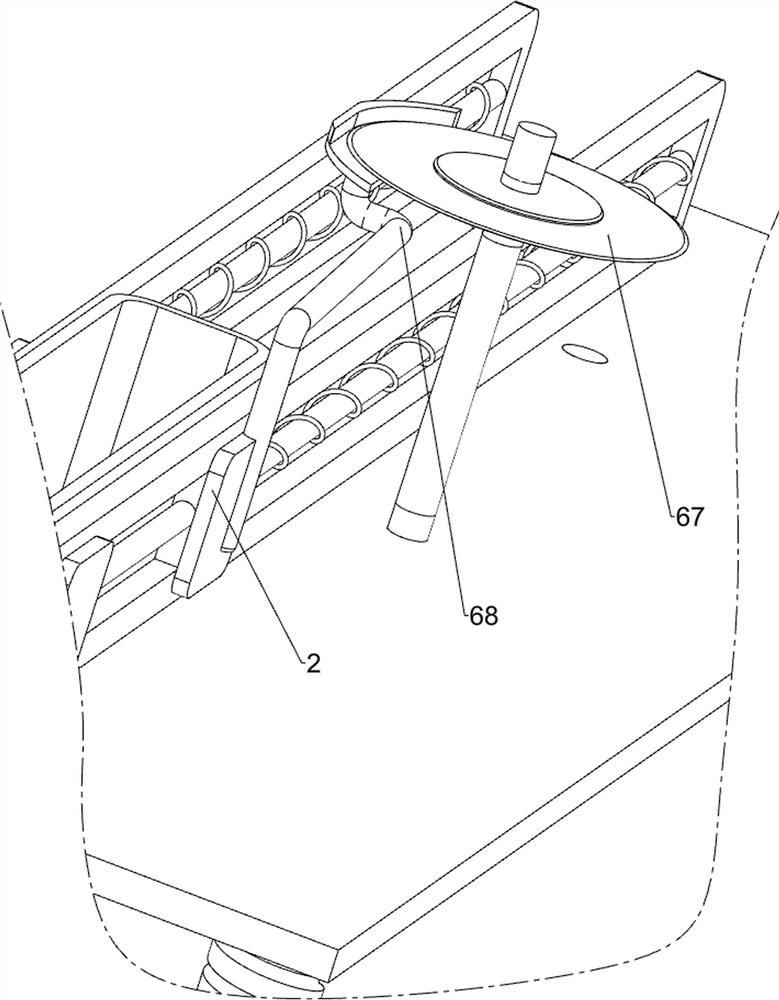

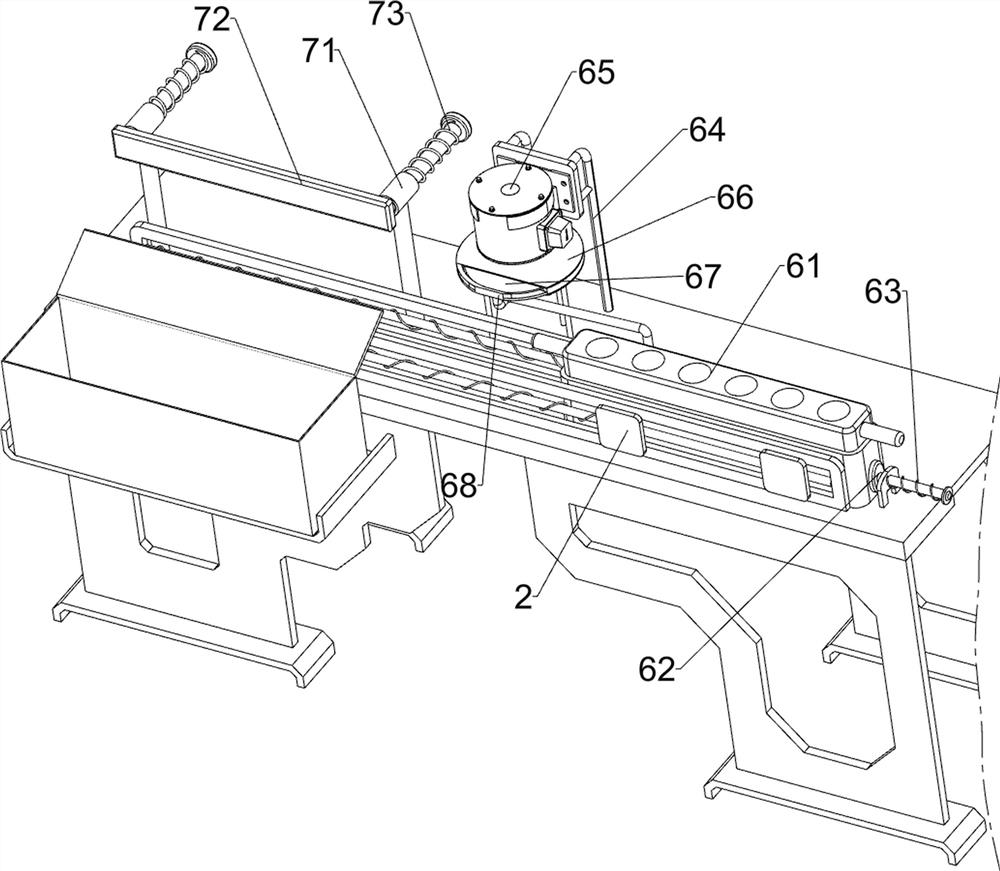

[0025] The moving cutting assembly 6 includes a placing frame 61, a sliding rod 62, an elastic member 63, a fixing frame 64, a dr...

Embodiment 2

[0029] On the basis of Example 1, as image 3 As shown, it also includes a drive assembly 8, the drive assembly 8 includes a guide rail 81, a transmission rack 82, a compression spring 83, a shaft 84, a worm 85, a worm wheel 86 and a toothless gear 87, and the bottom of the sliding frame 2 is connected with a guide rail 81 The guide rail 81 is slidably connected with a transmission rack 82, and a compression spring 83 is connected between the transmission rack 82 and the guide rail 81. The elastic force of the compression spring 83 is greater than that of the first return spring 3, and the output shaft of the drive motor 65 is connected to There is a shaft 84, the shaft 84 is connected with a worm 85 through the installation table 1, a worm wheel 86 is rotatably connected in the middle of the installation table 1, the worm wheel 86 cooperates with the worm 85, and the left side of the installation table 1 is rotatably connected with a toothless gear 87. The tooth-missing gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com