Method and application of preparing large-area two-dimensional molybdenum diselenide thin films with different layers

A molybdenum diselenide, large-area technology, applied in the direction of chemical instruments and methods, selenium/tellurium compounds, metal selenide/telluride, etc., can solve the problems of small size, complicated operation process, irregularity, etc., to achieve good Continuity and homogeneity, high crystallization quality, simple method results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0025] A method for preparing a large-area two-dimensional molybdenum diselenide film with different layers, comprising the following steps:

[0026] Step 1. In the corundum boat, mix 2mg of molybdenum trioxide (99.998%) and 0.2mg of sodium chloride evenly to obtain a mixed powder. The sheet is set above the mixed powder and the polished surface of the silicon dioxide substrate faces downward, wherein, in terms of parts by mass, the ratio of molybdenum trioxide to sodium chloride is 10:1, and the ratio of the silicon dioxide substrate to the mixed powder is The distance is 5mm;

[0027] Step 2, 25mg of selenium powder (99.999%) is placed in the furnace body, and the furnace body is operated three times to discharge the air and water vapor in the furnace body. Each operation is: the furnace body is evacuated with a vacuum pump state, feed argon gas (atmospheric pressure) in the furnace body; under the condition of feeding argon gas, the selenium powder and the mixed powder are...

Embodiment 3

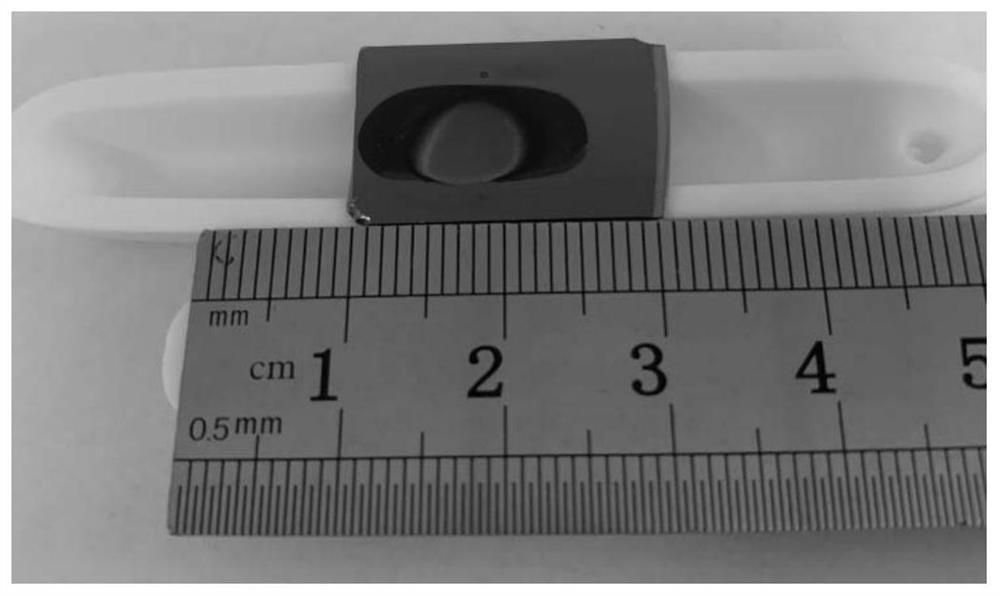

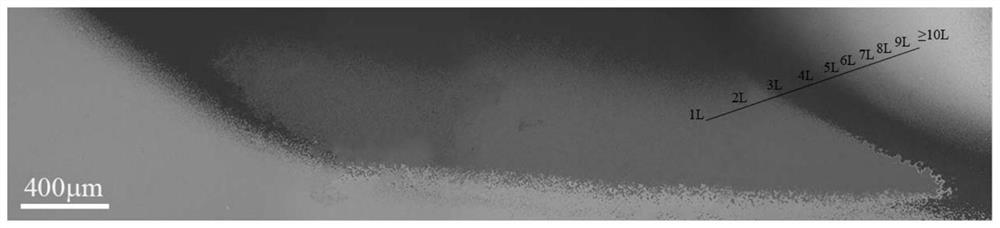

[0030] The two-dimensional molybdenum diselenide thin film gained in embodiment 3 is tested: the photograph of the two-dimensional molybdenum diselenide thin film of the large area different number of layers of preparation is as follows figure 1 As shown, the size of two-dimensional molybdenum diselenide film can reach centimeter scale. Its optical microscope image is figure 2 As shown, as the number of molybdenum diselenide layers increases, the contrast gradually changes from light purple to bright blue. At the same time, it can be clearly seen that the two-dimensional molybdenum diselenide film is very uniform and the single layer size is as long as 3mm.

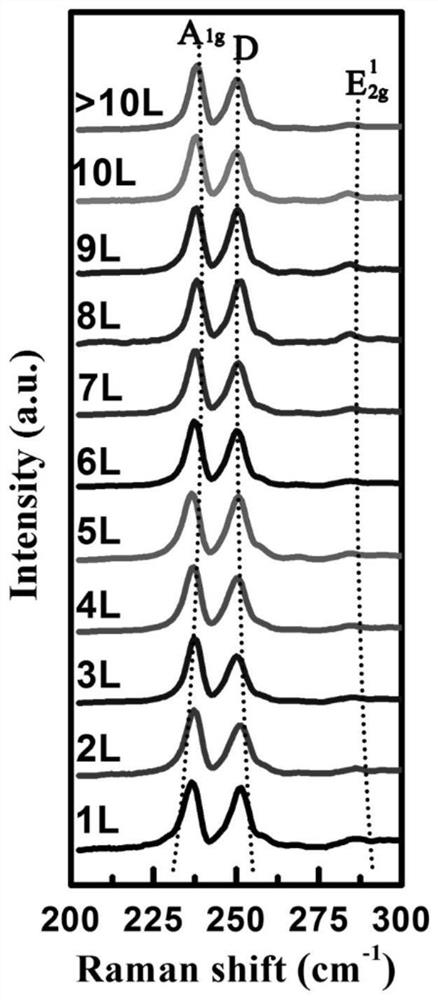

[0031] image 3 Raman spectra of two-dimensional molybdenum diselenide thin films with different layers and large areas prepared. Use a laser wavelength of 532nm to excite 1-10 layers and >10 layers of two-dimensional molybdenum diselenide thin films, and finally can obtain: A of a single-layer two-dimensional molybden...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap