High-impact 7-series aluminum alloy and preparation method thereof

An aluminum alloy, high impact technology, applied in the field of aluminum alloy materials, can solve problems such as the inability to achieve the ideal solution treatment effect, and achieve the effect of improving impact performance and improving dispersion strengthening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

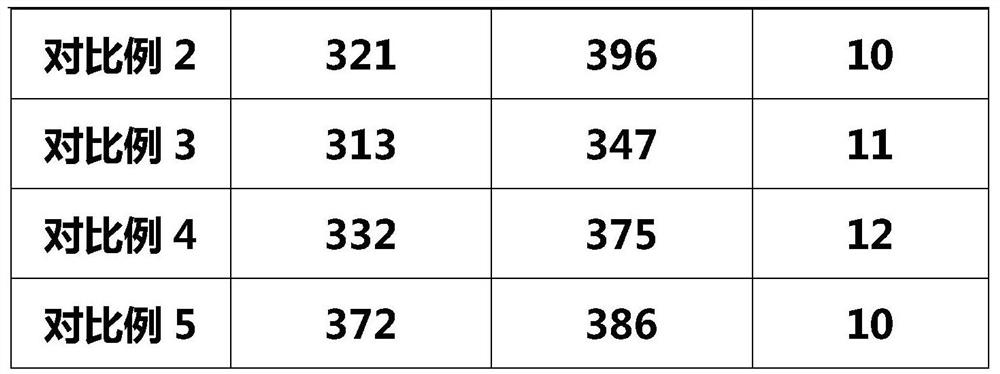

Examples

preparation example Construction

[0019] A method for preparing high-impact 7-series aluminum alloys, comprising the following steps: (a) smelting master alloys: using pure zinc ingots, pure aluminum ingots and pure magnesium ingots for Zn, Al, and Mg, and using aluminum ingots for Si, Fe, Mn, Cu, and Cr Silicon intermediate alloy, aluminum-iron intermediate alloy, aluminum-manganese intermediate alloy, aluminum-copper intermediate alloy and aluminum-chromium intermediate alloy; put the pure aluminum ingot into the furnace, set the furnace gas temperature to 760°C, keep the pure aluminum ingot for 30 minutes after melting Then add aluminum-copper master alloy, aluminum-manganese master alloy, aluminum-iron master alloy and pure magnesium ingots into the smelting furnace according to the block weight and size from large to small, and then raise the temperature of the furnace gas by 15°C and keep it warm until the master alloy After all the magnesium ingots are melted, the temperature of the furnace gas is increa...

Embodiment 1

[0025] A high-impact 7-series aluminum alloy, the high-impact 7-series aluminum alloy includes the following components: Si0.15%, Fe1.05%, Cu0.5%, Mn0.4%, Mg2.0%, Cr0.10% , Zn7.0%, Zr0.3%, Ti0.05%, other alloying elements individually ≤0.05%, total less than 0.15%.

Embodiment 2

[0027] A high-impact 7-series aluminum alloy, Si0.1%, Fe0.06%, Cu0.6%, Mn0.4%, Mg2.2%, Cr0.12%, Zn7.5%, Zr0.25%, Ti0 .05%, other alloying elements individually ≤0.05%, less than 0.15% in total, and the balance is Al.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com