Web plate perforated profile steel partially-wrapped recycled concrete beam and construction method thereof

A technology of recycled concrete and web, applied in the processing of building materials, structural elements, building components, etc., can solve the problems of lack of good connection of concrete, many construction steps of composite beams, unfavorable overall performance of components, etc., and achieve easy hoisting. and transport, improve the performance of individual work, improve the effect of lateral support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

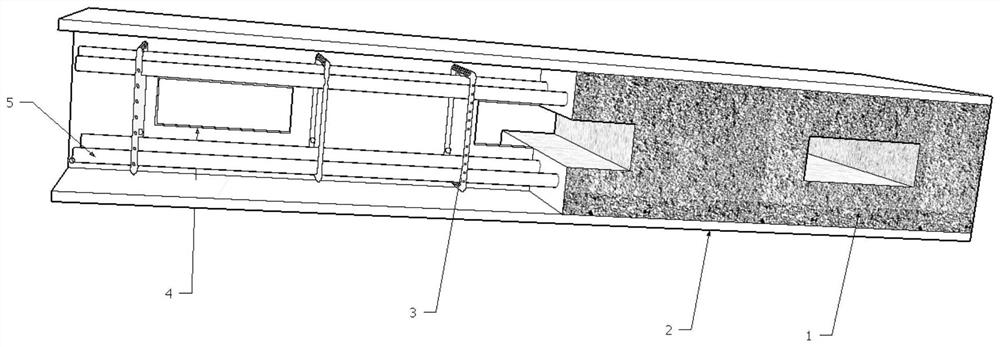

[0039] The present invention also provides a construction method for partially wrapping recycled concrete beams with open-hole steel in the web, including the following steps:

[0040] S1: Open web openings 4 on both sides of the web of the section steel 2, then place the array of reinforcement components inside the section steel 2, and pour the prepared recycled concrete 1 into the inside of the section steel 2 to form a prefabricated part;

[0041] Specifically, the section steel 2 or the completed section steel 2 is placed in place in the component manufacturing plant, holes are opened on both sides of the web of the section steel 2 according to the designed spacing, and then the stirrups 3 are inserted into the shape in sequence according to the designed spacing;

[0042] Between the two sides of the web of the section steel 2 and between the upper and lower flanges, insert the longitudinal reinforcement 5 into the stirrup 3, bind the stirrup 3 and the longitudinal reinforc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com