Multi-branch horizontal well gas drainage technology in goaf of coal mine

A technology for horizontal wells and goafs, which is applied in gas discharge, mining equipment, directional drilling, etc. It can solve the problems of affecting the drainage effect, large difference in drainage volume, and high drilling cost, achieving valuable time and safety guarantees, The effect of improving comprehensive economic benefits and shortening the time of gas extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

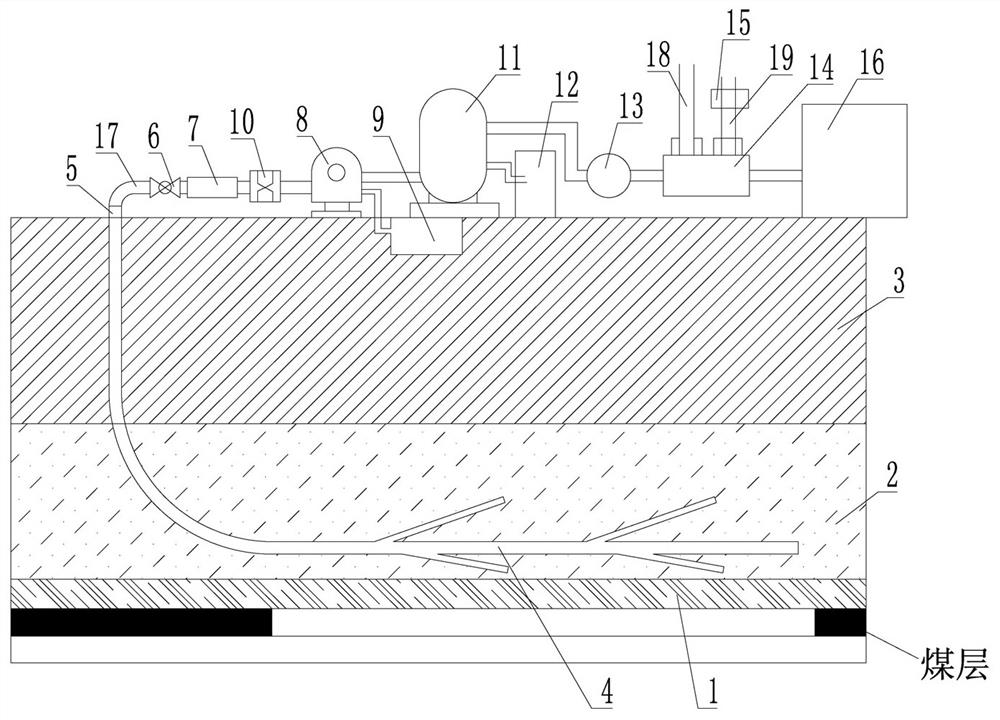

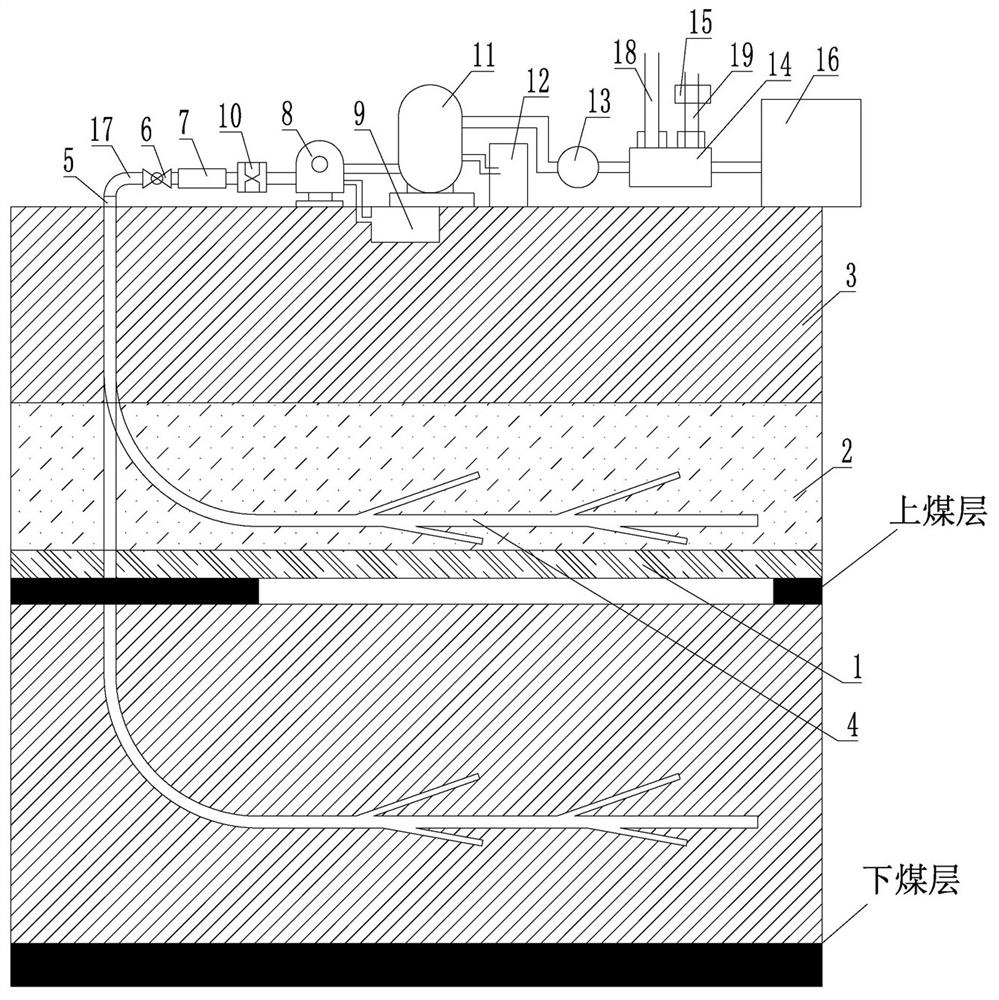

[0057] like Figure 1-3 As shown, a multi-branch horizontal well drainage process for goaf gas in coal mines includes the following steps:

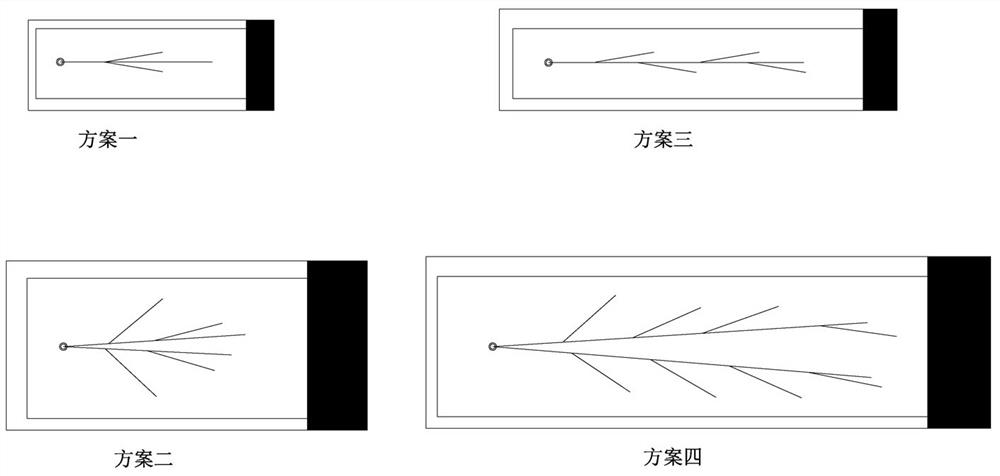

[0058] (1) Calculate the height of the caving zone 1 and fracture zone 2 in the upper part of the goaf according to the geological data such as the nature of the surrounding rock, the mining height of the coal seam, and the number of coal seams, determine the gas enrichment area in the goaf, and determine the drilling azimuth layout plan;

[0059] (2) Select the wellbore structure according to the number of target coal seams and the distribution of corresponding gas enrichment areas;

[0060] (3) Select a reasonable drilling tool assembly according to the formation structure and wellbore structure design;

[0061] (4) Calculating the wellbore trajectory according to the drilling azimuth layout scheme in step (1); ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com