Method for identifying leakage point of casing-damaged oil well

A leakage point and oil well technology, which is applied in the identification of the water output position of casing damaged oil wells and the leakage point identification of casing damaged oil wells, can solve the problems of casing damage caused by packers, unfavorable wellbore integrity, and complicated process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

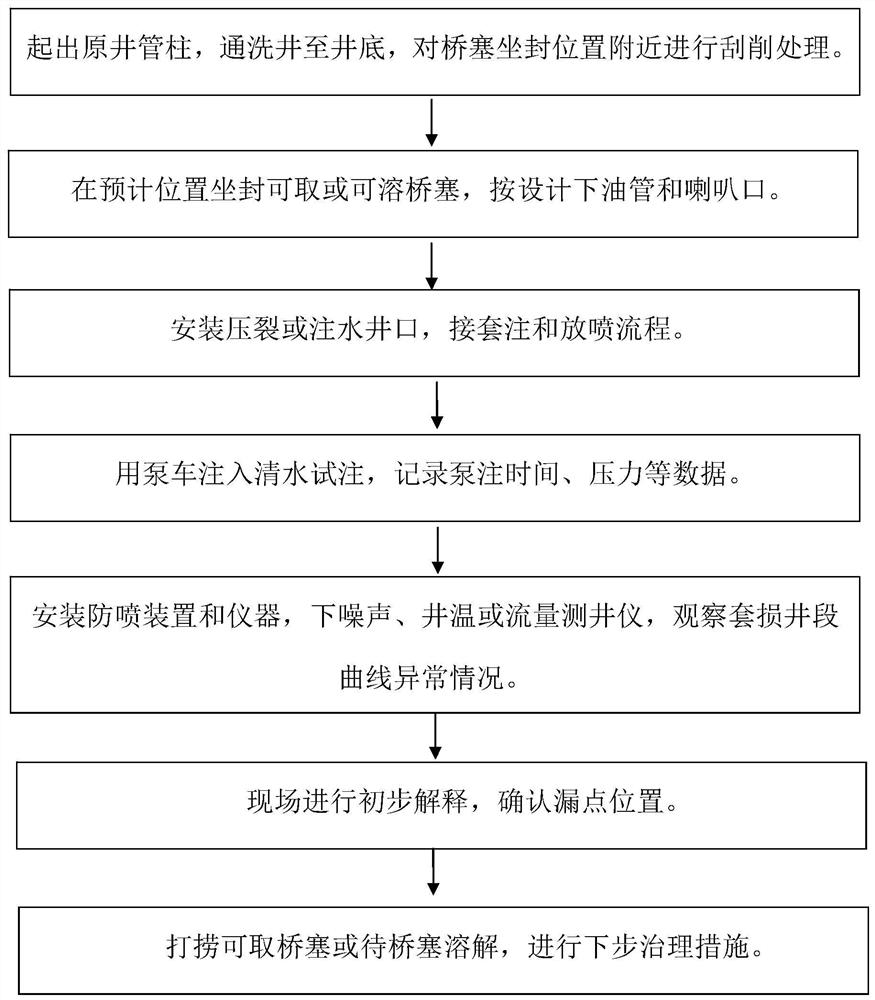

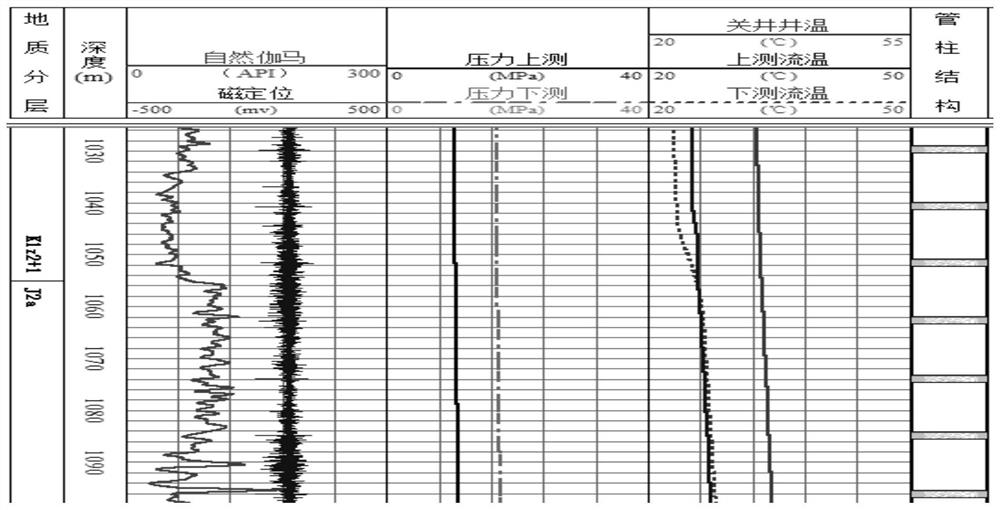

[0044] This embodiment provides a method for identifying the leakage point of a casing damaged oil well. The fluid flow is generated by artificial excitation in the wellbore, and the noise logging instrument is used to measure the noise amplitude and frequency generated when the fluid flows in the cement ring tunnel or formation outside the pipe. To determine the location of fluid generation, and combine well temperature, flow and other instruments to improve the accuracy and success rate of leak finding and channel finding. Specific steps are as follows:

[0045] S1, the original well string is lifted out, and the well is cleaned to the bottom of the well with a pass gauge to scrape the bridge plug near the setting position.

[0046] S2, the bridge plug (perforation section 1530.00-1533.00m) is available for setting at 1528m. According to the setting position of the bridge plug, the tubing and bell mouth are lowered according to the engineering design.

[0047] S3, install fracturi...

Embodiment 2

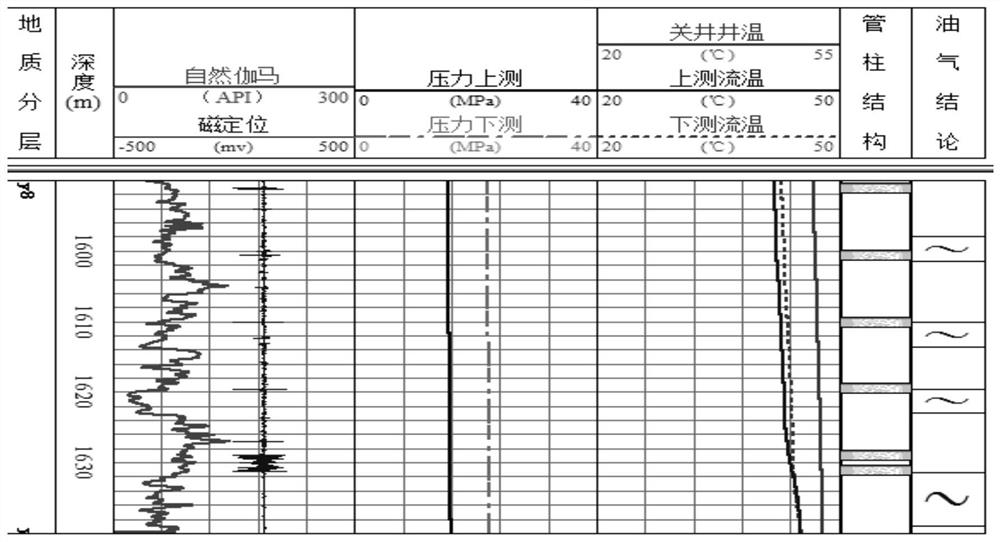

[0054] This embodiment provides a method for identifying the leakage point of a casing damaged oil well. The fluid flow is generated by artificial excitation in the wellbore, and the noise logging instrument is used to measure the noise amplitude and frequency generated when the fluid flows in the cement ring tunnel or formation outside the pipe. To determine the location of fluid generation, and combine well temperature, flow and other instruments to improve the accuracy and success rate of leak finding and channel finding. Specific steps are as follows:

[0055] S1, the original well string is lifted out, and the well is cleaned to the bottom of the well with a pass gauge to scrape the bridge plug near the setting position.

[0056] S2, set the soluble bridge plug at 1767m (perforation section 1769-1772m), and lower the tubing and bell mouth according to the engineering design.

[0057] S3, install fracturing or water injection wellhead, socket injection and blowout process.

[005...

Embodiment 3

[0063] This embodiment provides a method for identifying the leakage point of a casing damaged oil well. The fluid flow is generated by artificial excitation in the wellbore, and the noise logging instrument is used to measure the noise amplitude and frequency generated when the fluid flows in the cement ring tunnel or formation outside the pipe. To determine the location of fluid generation, and combine well temperature, flow and other instruments to improve the accuracy and success rate of leak finding and channel finding. Specific steps are as follows:

[0064] S1, the original well string is lifted out, and the well is cleaned to the bottom of the well with a pass gauge to scrape the bridge plug near the setting position.

[0065] S2, set the soluble bridge plug at the expected depth, and lower the tubing and bell mouth according to the design.

[0066] S3, install fracturing or water injection wellhead, socket injection and blowout process.

[0067] S4: Use a pump truck to injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com