Absorption heat exchanger capable of realizing multi-area independent heat supply

An absorption and heat exchanger technology, applied in the field of energy saving, to achieve the effect of reducing the number of equipment, reducing initial investment and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings.

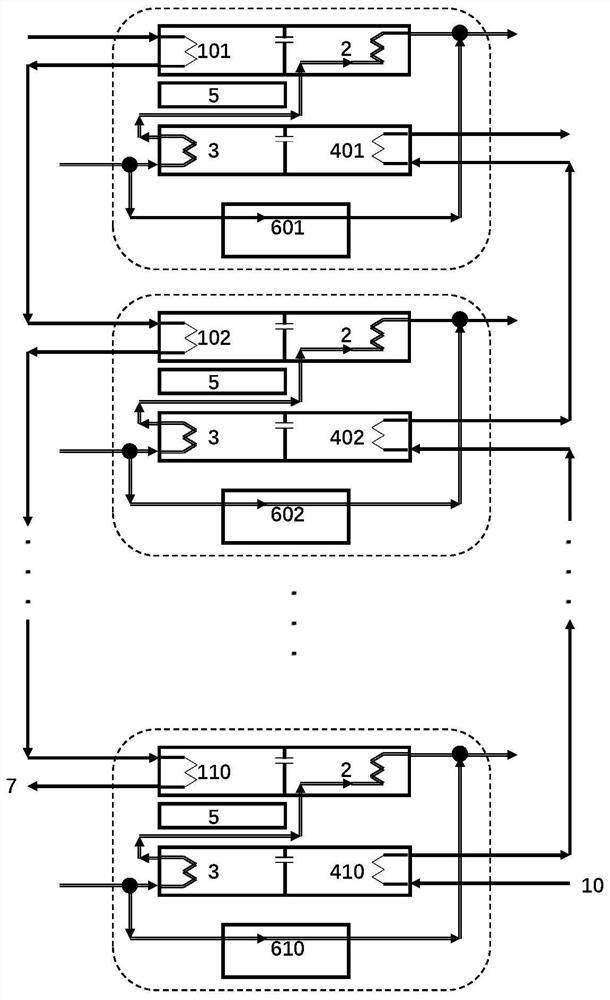

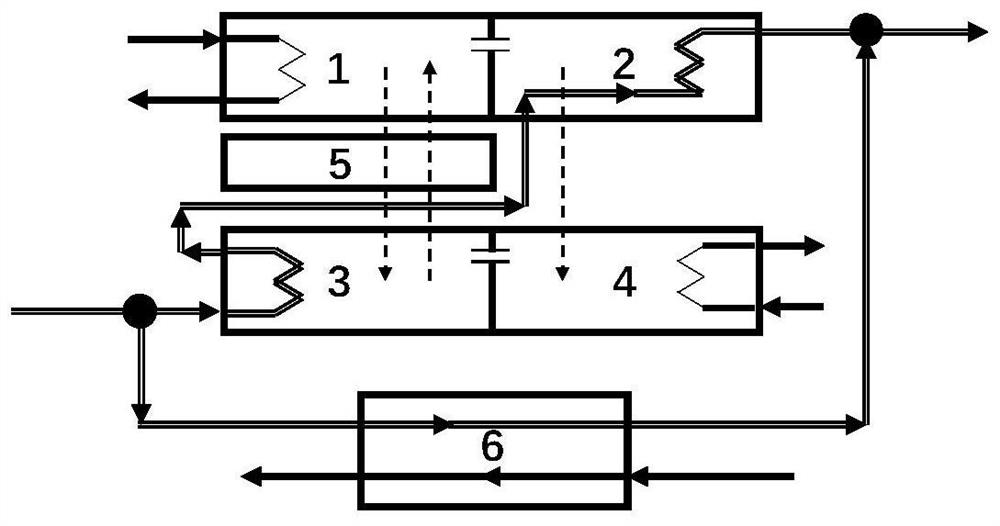

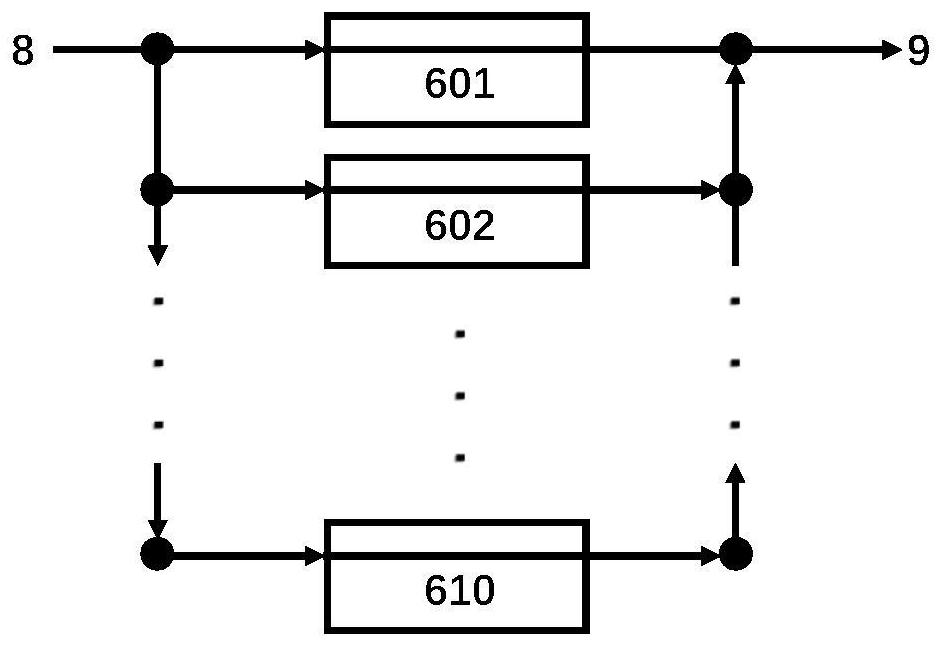

[0032] Such as Figure 1 ~ Figure 3 The shown embodiment 1 of a multi-stage high-efficiency large-temperature-difference absorption heat exchanger (heat pump) of the present invention that can realize multi-region independent heat supply includes: p-stage internal independent absorption heat exchange process, generator hot water Pipeline, evaporator hot water pipeline, water-water plate exchange water pipeline and p-level independent cold water pipeline, where 2≤p≤10, the evaporation pressure in the absorption cycle of each level increases step by step; that is, each The evaporation temperature of the evaporator 4 (that is, the saturated water temperature in the cavity) increases sequentially; the hot water pipeline of the generator is connected to the generator 1 of each level in the forward direction, and the hot water pipeline of the evaporator is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com