Gantry crane swing mechanism driving system

A technology of slewing mechanism and drive system, which is applied in the direction of electromechanical devices, electric components, and control of mechanical energy, etc. It can solve the problems of high maintenance costs and long maintenance time of the drive system of the slewing mechanism of the door machine, and achieve sensitive protection and stability. Sexuality, the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

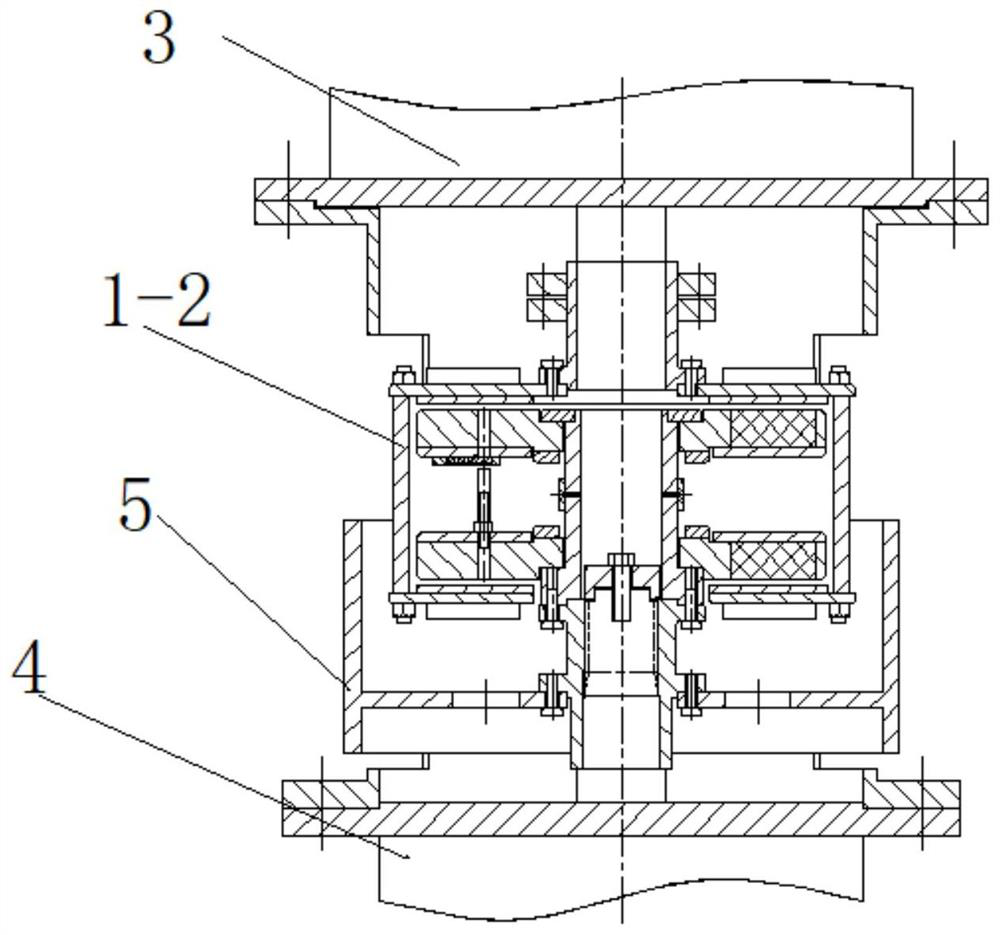

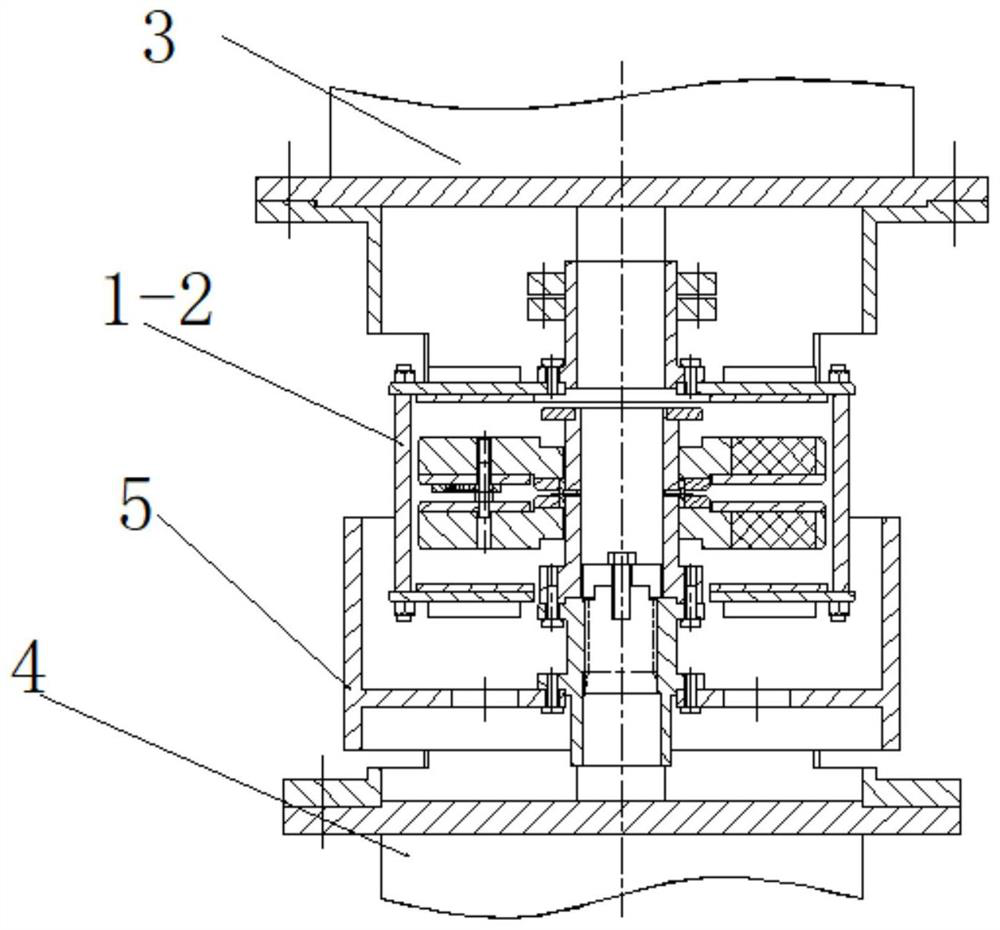

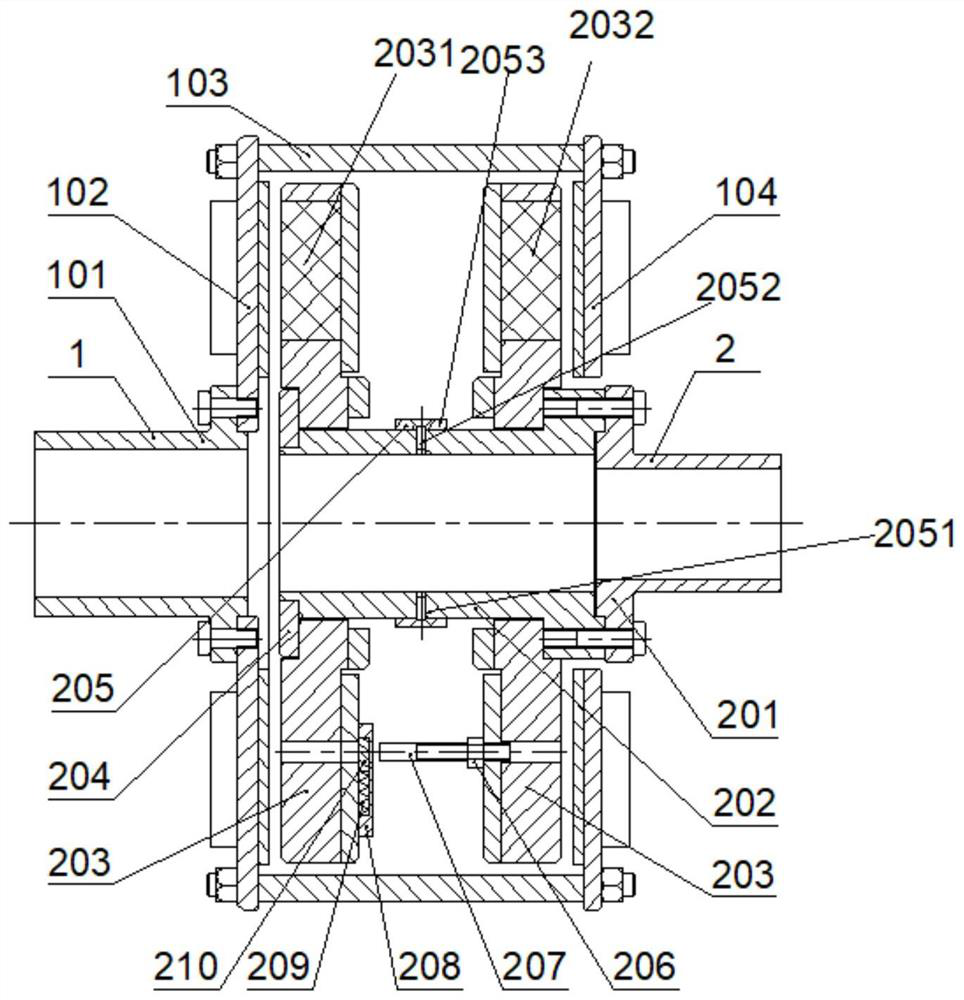

[0032] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

[0033] A driving system for a door machine turning mechanism, including a motor 3; the motor 3 is connected to a speed reducer 4 through a torque-limiting permanent magnet coupling 1-2; the invention discloses a driving system for a door machine turning mechanism. The invention uses a torque-limiting permanent magnet coupling to replace the limit torque limiter, which makes the protection action of the entire drive system more sensitive, and can automatically recover at the same time, reducing or avoiding damage to parts.

[0034] As a preference, the torque-limiting permanent magnet coupling 1-2 in the present invention is connected to the motor shaft through a connecting piece; the above-mentioned connecting piece can also be a bushing structure, which can be called the first bushing 101; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com