Crystal rod cutting device and crystal rod cutting method

A cutting device and crystal rod technology, which is applied to fine working devices, working accessories, manufacturing tools, etc., can solve the problems of cutting line vibration and uneven surface of silicon wafers, and achieve the effect of avoiding uneven cutting surfaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

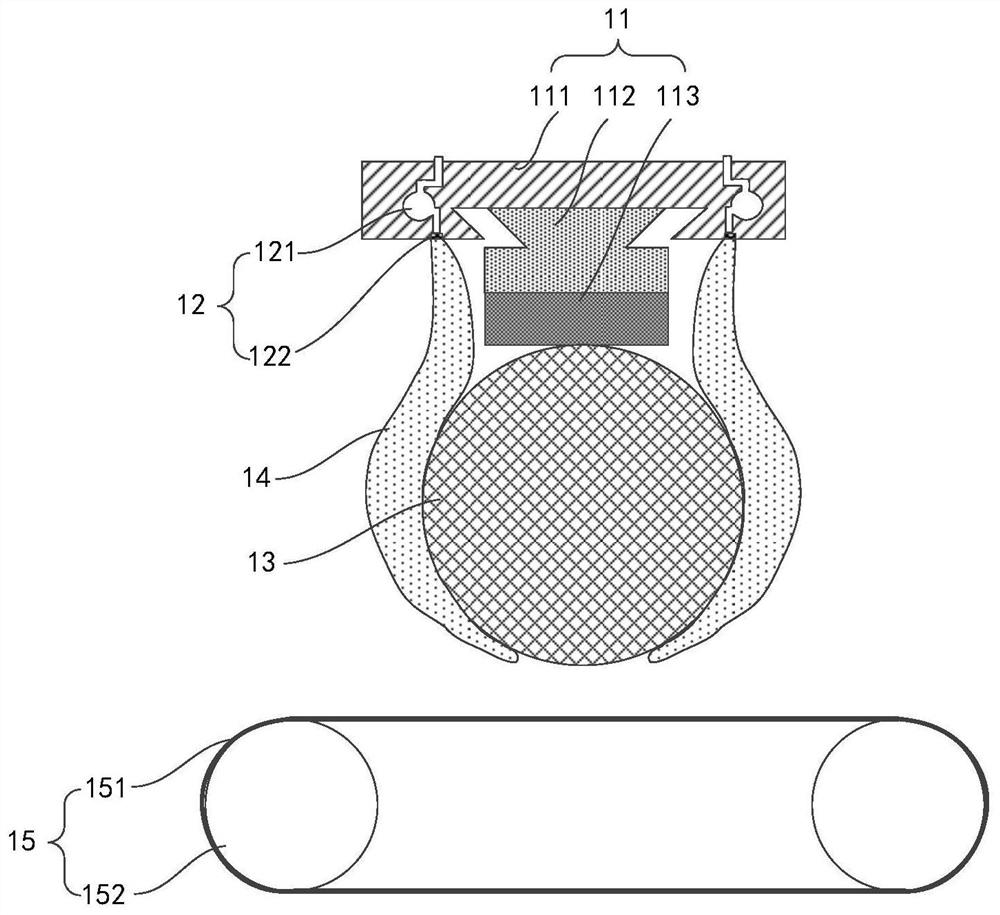

[0029] Thus, please refer to FIG. 1, which is a schematic structural diagram of a crystal rod cutting device provided by an embodiment of the present invention. Figure 1

[0031] Please continue to refer to FIG. 1, the feeding table 11 may specifically include an undercut wedge joint 111, a material table 112 and a support plate 113,

[0032] In the embodiment of the present invention, the mortar supply unit 12 may include a mortar supply pipe 121 and a mortar discharge port 122, which

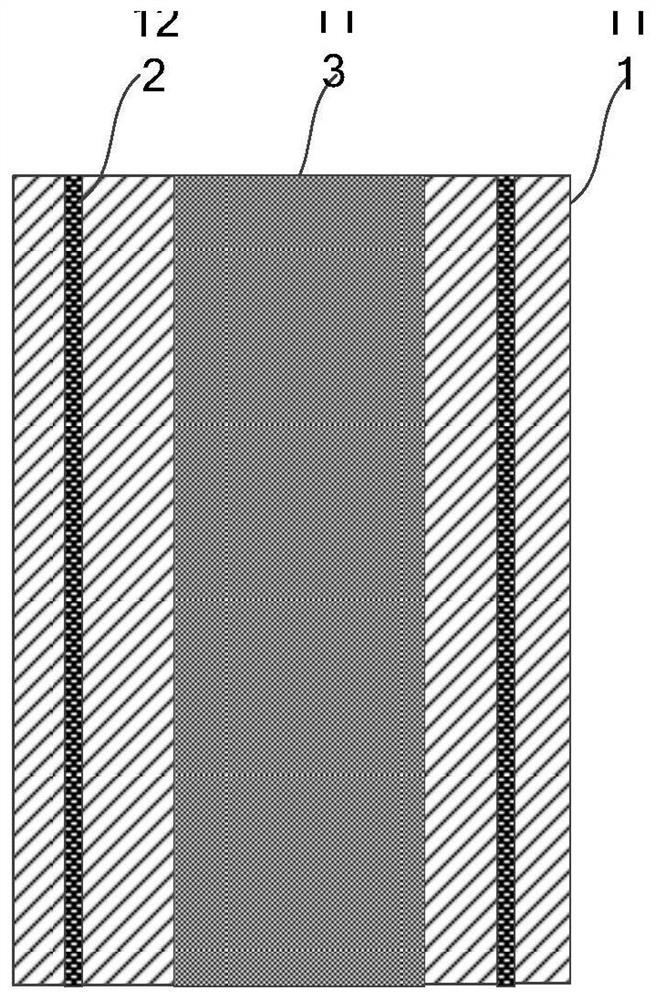

[0033] Please refer to FIG. 2, which is a schematic diagram of a mortar outlet provided in an embodiment of the present invention. As shown in Figure 2, the present invention is implemented

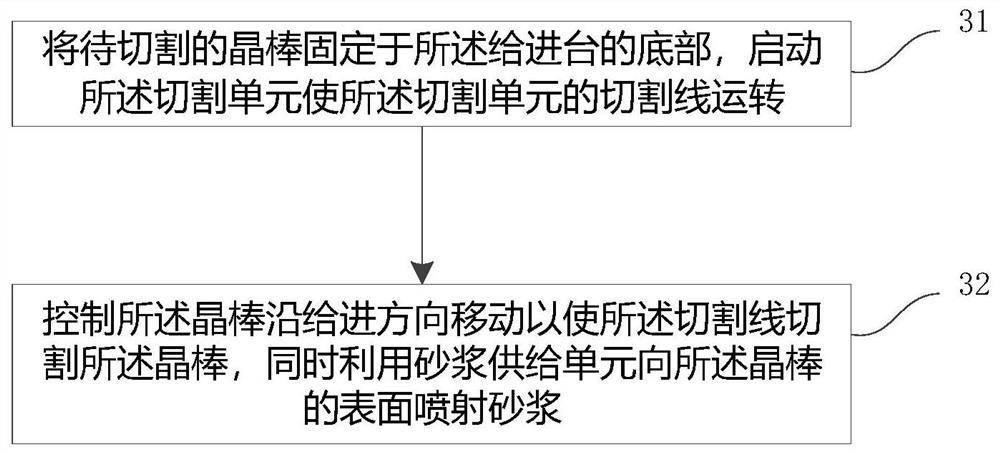

[0037] Please refer to FIG. 3, which is a schematic flowchart of a method for cutting an ingot according to an embodiment of the present invention. As shown in Figure 3,

[0043] According to the cutting speed, the mortar supply speed of the mortar supply unit is controlled to control the surface temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com