Degradable polylactic acid plate and preparation method thereof

A technology of polylactic acid and L-polylactic acid, applied in the field of building materials, can solve the problems of high price of polylactic acid, high price, restrict the promotion of PLA sheets, etc., and achieve the effect of high safety factor, low cost, and avoiding the use of petroleum-based auxiliary materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail through specific examples below.

[0035] The following examples have no special instructions, and all raw materials can be obtained through commercial channels.

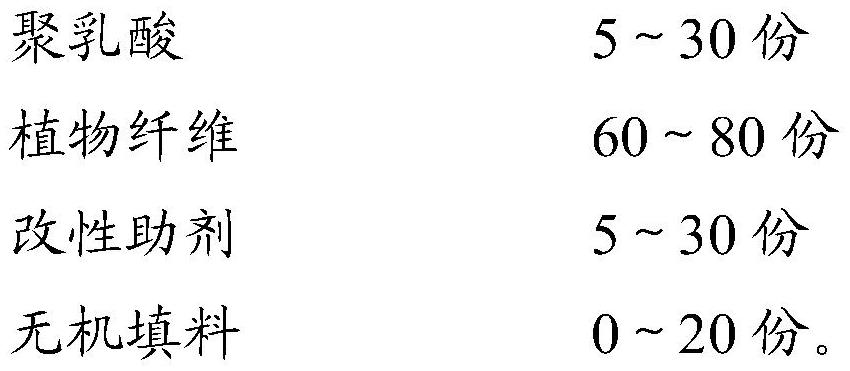

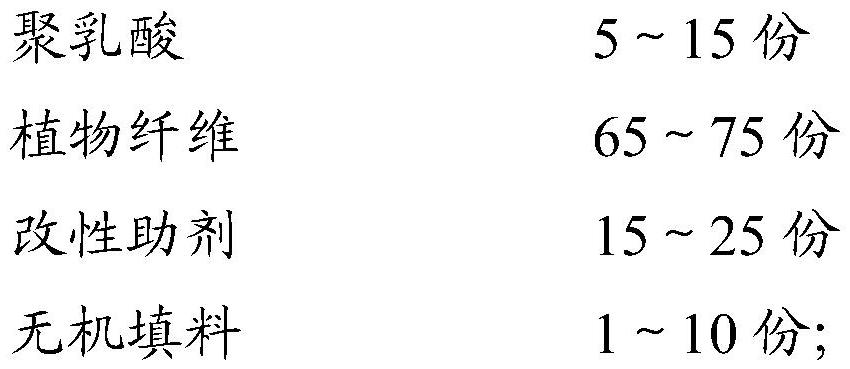

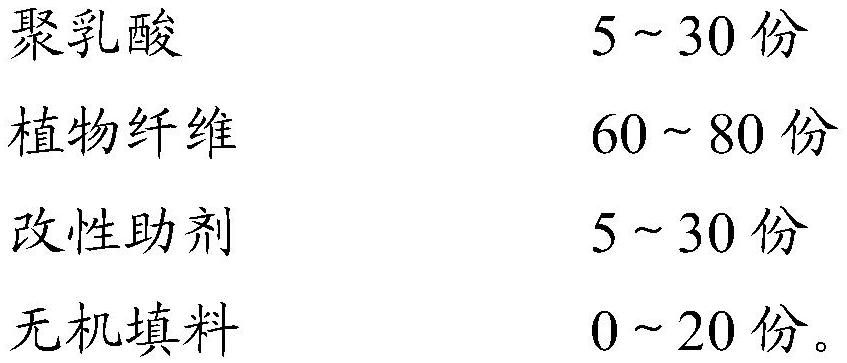

[0036] The present invention provides Embodiment 1-Embodiment 3, wherein the composition of each embodiment is shown in Table 1.

[0037] Table 1

[0038]

[0039] It can be seen from Table 1 that the degradable polylactic acid sheets with high plant fiber content provided in Examples 1-3 are prepared from plant fibers, polylactic acid, inorganic fillers, toughening agents, lubricants, chain extenders, hydrolysis-resistant agent, compatibilizer composition.

[0040] Among them, the polylactic acid is PLLA with a relative molecular weight of 100,000. The optical purity of L-polylactic acid is 98%-99.5%, and the melt flow index is 5-30g / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com