Application of modified nano graphene oxide as as a chemical for improving the oil recovery of low-permeability reservoir

A recovery factor and modifier technology, applied in the field of chemical materials, can solve the problems of activator channeling, high formation adsorption loss, complex pore structure, etc., and achieve good dispersion, low formation adsorption loss, safe and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

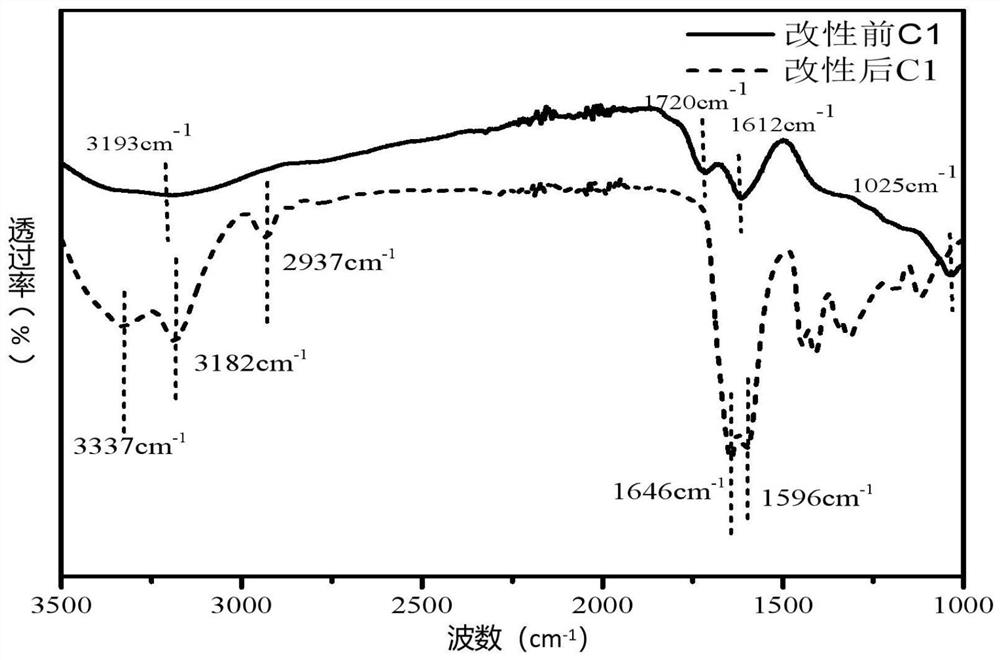

Method used

Image

Examples

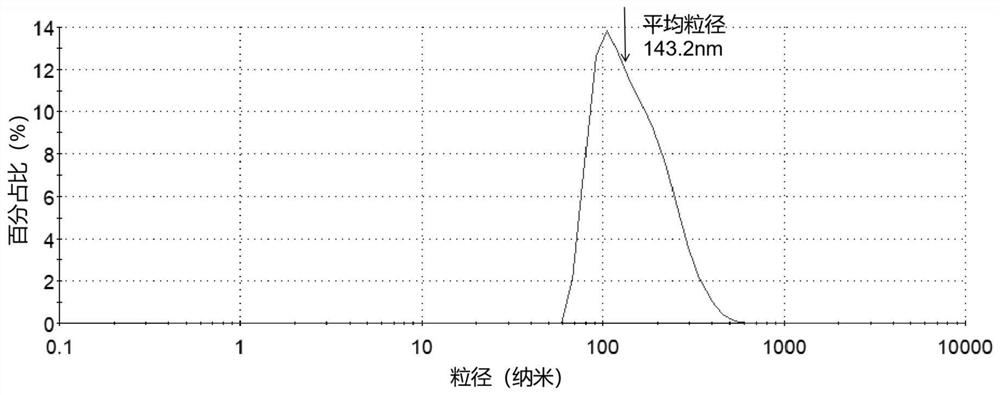

Embodiment 1

[0085] 1. Measure 250mL of concentrated sulfuric acid with a mass fraction of 98%, pour it into a 500mL glass beaker with a stirring bar and stir, slowly add 5.00g of 15000 mesh microcrystalline graphite powder into the beaker, and perform magnetic After stirring for 30 minutes, slowly add 25 g of ground potassium permanganate powder while stirring, continue to keep stirring in the ice-water bath for 120 minutes, remove the ice-water bath, raise the temperature to 37°C, continue to keep stirring for 120 minutes, and slowly add deionized water, Control the temperature below 60°C, add water until the temperature of the reaction system no longer rises, add 5mL of 30% concentration of H 2 o 2 ;

[0086] 2. Place the solution in a centrifuge, set the speed at 800 rpm, and wait for 5 minutes. After standing still, filter to remove large particles of impurities, transfer it to a 1000mL beaker, add deionized water to wash until pH ≥ 6, and obtain microcrystalline graphite oxide gel; ...

Embodiment 2

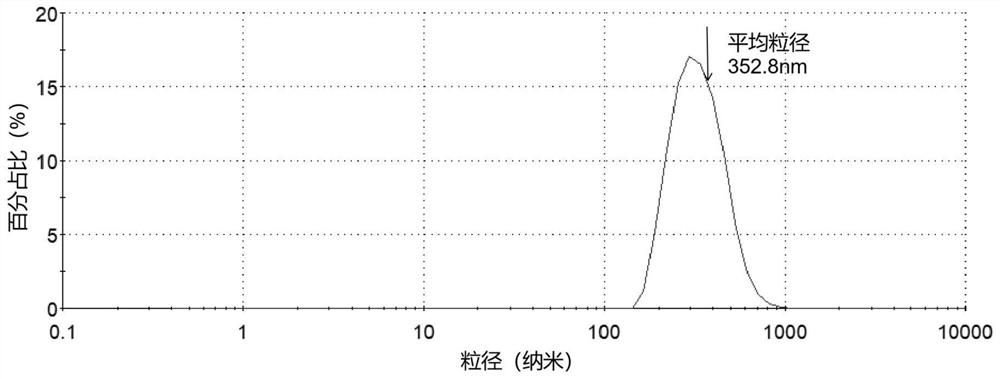

[0092] In this example, 8000-mesh microcrystalline graphite is used to replace 15000-mesh microcrystalline graphite powder in Example 1, and the same method and steps as in Example 1 are used to obtain modified nano-graphene oxide modified with polyethyleneimine to enhance oil recovery. agent, denoted as C2.

Embodiment 3

[0094] The preparation method of this example is basically the same as that of Example 1, except that 3000-mesh microcrystalline graphite powder is used in step 1, and the final product obtained is denoted as C3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com