Method for producing aviation kerosene and co-producing clean fuels from coal tar

A technology for aviation kerosene and low-temperature coal tar, applied in the field of coal tar hydrogenation, can solve the problems of high hydrogen consumption, low yield and high raw material cost in deoxygenation reaction, and achieve the effects of low cost, reduced hydrogen consumption and low freezing point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

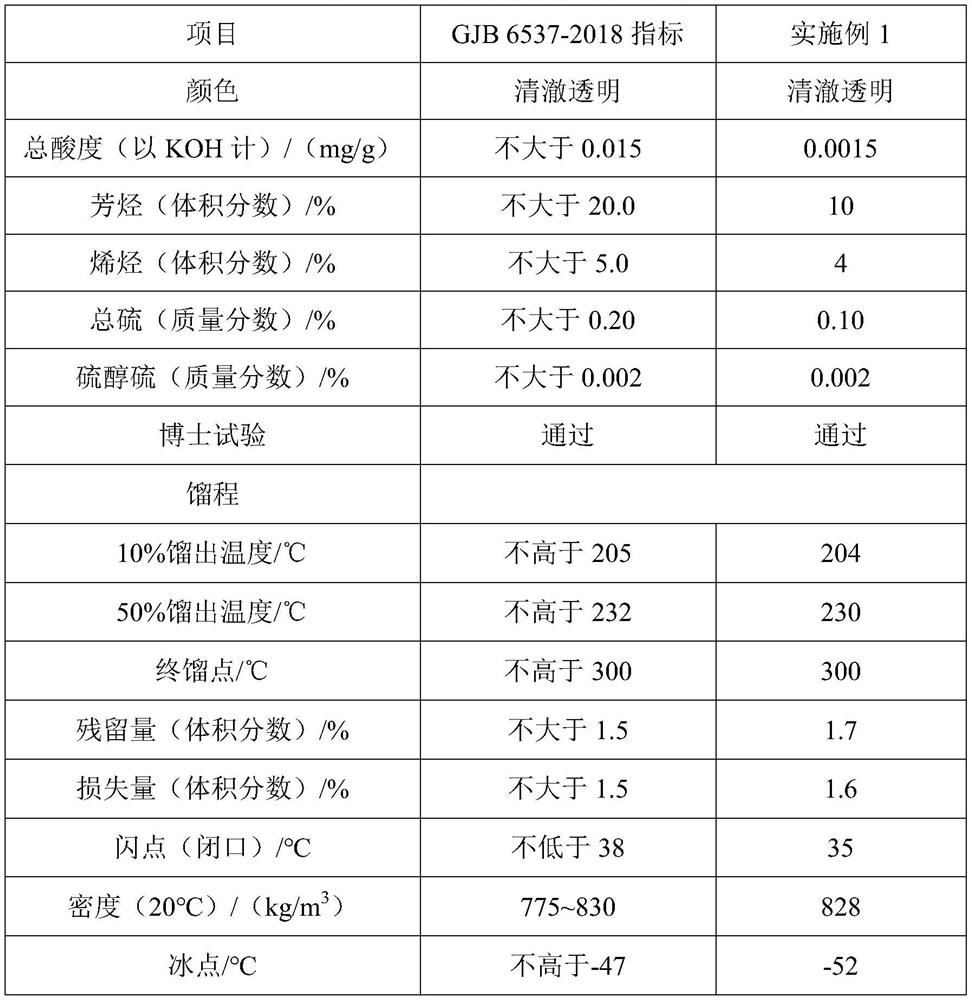

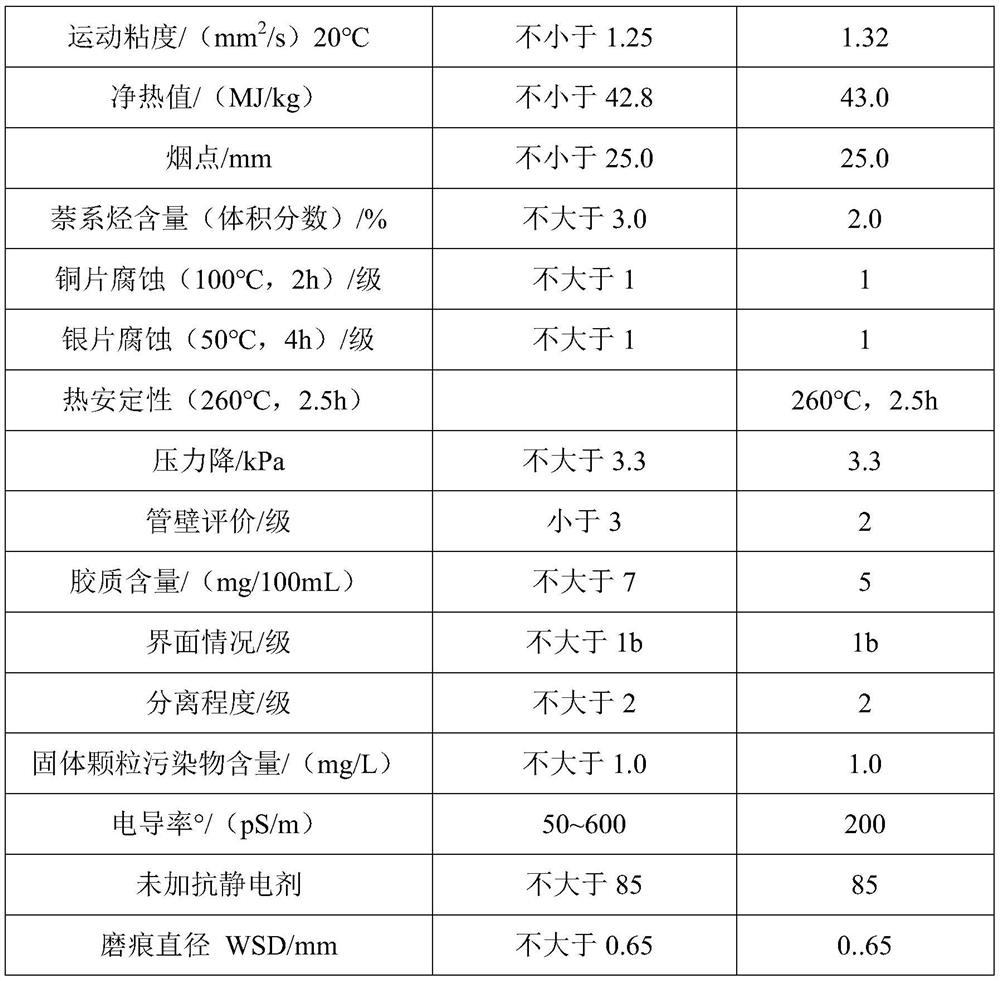

Embodiment 1

[0040] In low-temperature coal tar as the raw material, often under reduced pressure distillation cut 200 ℃ ~ 400 ℃ fraction, and the addition amount of 40wt% high temperature coal tar anthracene oil complex segment, to obtain purified raw material, mixed with hydrogen in the hydrofining reactor, followed by purification of commercial hydrogenation protecting agent and a catalyst bed temperature of 380 deg.] C in the hydrogenation, pressure of 10 MPa or, the hydrogen oil 1200:1 volume ratio, the volume of the liquid space velocity was 0.4h -1 , Hydrorefining reaction, the resulting product was saturated deep hydrogenation reactor, hydrogenation of doing business with a saturation catalyst bed, at a temperature of 420 ℃, the hydrogenation pressure is 14MPa, the hydrogen oil ratio 1500:1 volume, liquid volume space velocity of 0.3h -1 , Saturated depth hydrogenation reaction, the resulting product is used in the hydroisomerization reactor, with business hydroisomerization catalyst b...

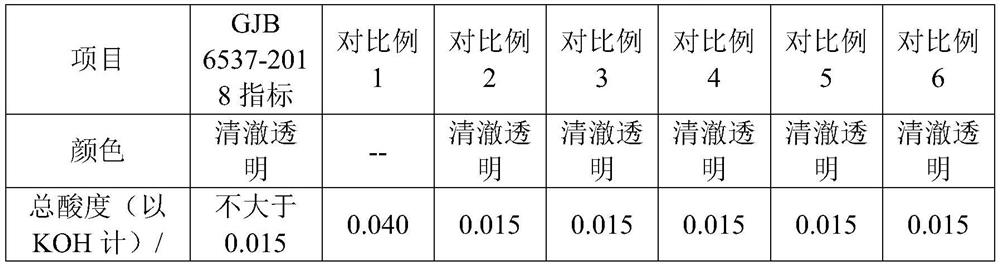

Embodiment 2

[0046] Coal tar as the raw material to neutralize the low temperature, vacuum distillation process is often cut -1 , A hydrotreating reactor in the hydrogenation reactor is saturated in depth hydrotreating reactor product business with saturated deep hydrogenation catalyst bed at a temperature of 420 ℃, the hydrogenation pressure is 14MPa, the hydrogen oil ratio was 1500 by volume :1, the volume of the liquid space velocity was 0.3h -1 , Saturated depth hydrogenation reaction, the resulting product is used in the hydroisomerization reactor, with business hydroisomerization catalyst bed, at a temperature of 360 deg.] C, a pressure 8MPa hydrogenation, the hydrogen oil volume ratio 1100:1, liquid space velocity of 0.5h -1 Hydroisomerization reaction, the resulting product of the fractionator, fractionation obtained 3 jet fuel, gasoline and diesel products.

[0047] After analysis, the No. 3 of the present embodiment, jet fuel yield of 65wt%

Embodiment 3

[0049] In low-temperature coal tar as the raw material, often under reduced pressure distillation cut 200 ℃ ~ 400 ℃ fraction, and the addition amount of 35wt% high temperature coal tar anthracene oil complex segment, to obtain a purified material, the hydrogen mixed in the hydrofining reactor, followed by purification of commercial hydrogenation protecting agent and a catalyst bed temperature of 380 deg.] C in the hydrogenation, pressure of 10 MPa or, the hydrogen oil 1200:1 volume ratio, the volume of the liquid space velocity was 0.4h -1 , A hydrotreating reactor in the hydrogenation reactor is saturated in depth hydrotreating reactor product business with saturated deep hydrogenation catalyst bed at a temperature of 420 ℃, the hydrogenation pressure is 14MPa, the hydrogen oil ratio was 1500 by volume :1, the volume of the liquid space velocity was 0.3h -1 , Saturated depth hydrogenation reaction, the resulting product is used in the hydroisomerization reactor, with business hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap