Steel wire continuous tempering electric heating furnace

A heating furnace and thermal power technology, applied in the direction of heat treatment furnaces, furnaces, furnace types, etc., can solve the problems of heat loss, increased workload, poor tempering temperature uniformity, etc., and achieve reduced workload, strong practicability, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

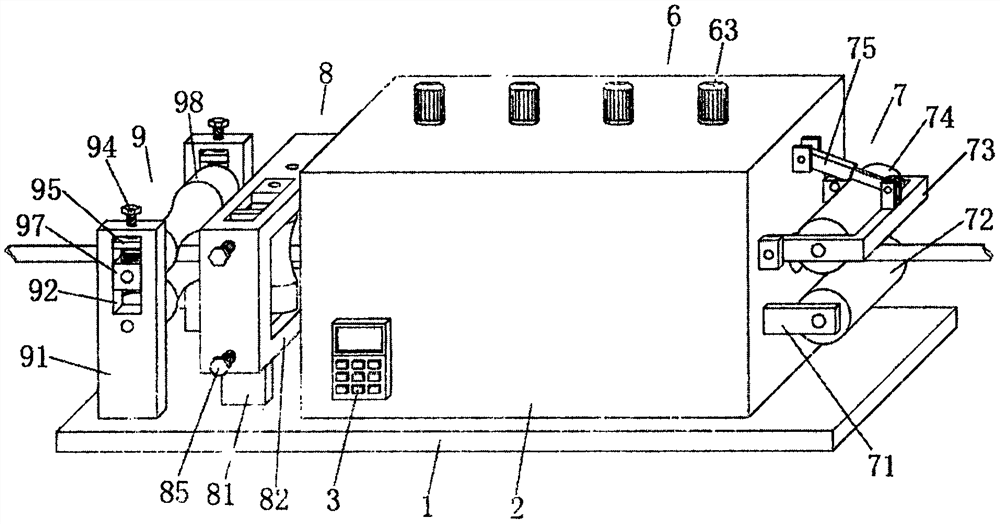

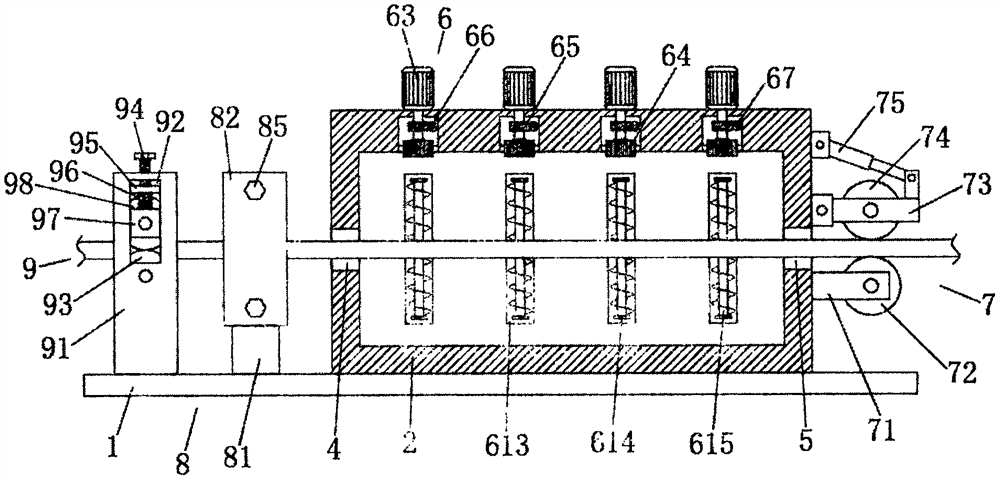

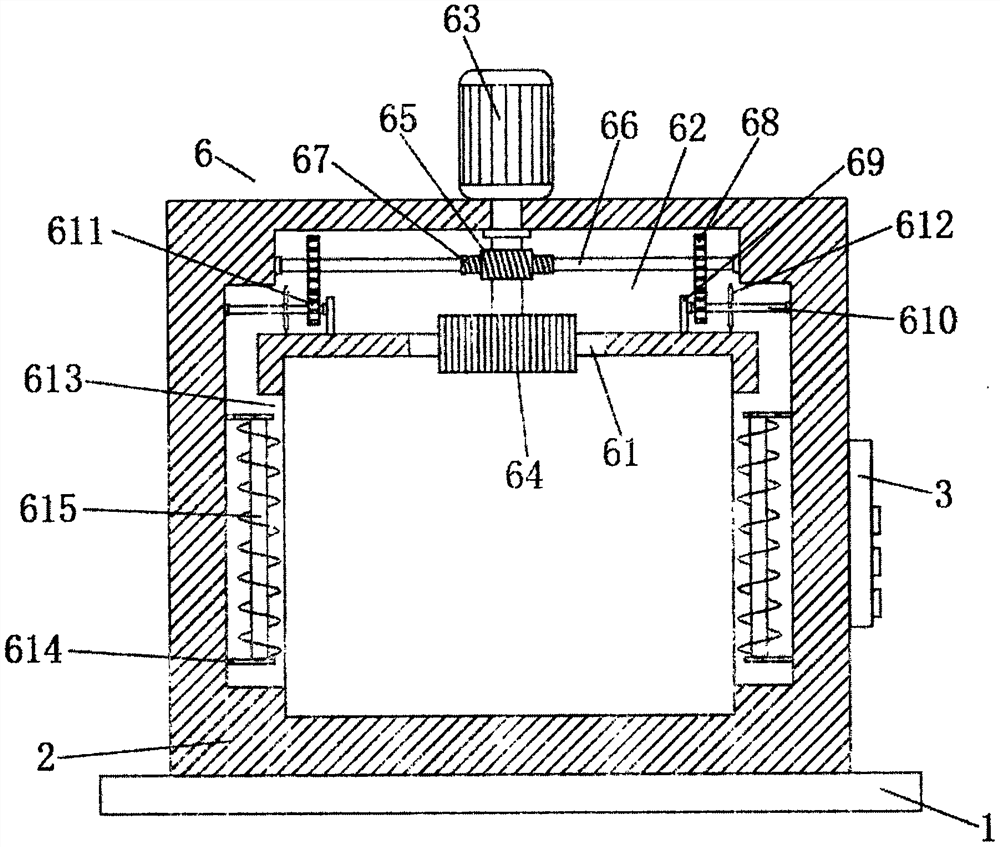

[0026] The steel wire continuous tempering electric heating furnace includes a bottom plate 1, a furnace body 2, a control panel 3, a material inlet 4, a material outlet 5, a tempering mechanism 6, a limit mechanism 7, a longitudinal cleaning mechanism 8 and a horizontal cleaning mechanism 9. One end of the top of the bottom plate 1 is fixedly connected with a furnace body 2, a control panel 3 is fixedly installed on one side of the furnace body 2, and a feed inlet 4 is provided on the side adjacent to the control panel 3 on the outside of the furnace body 2 , the side of the furnace body 2 away from the feed port 4 is provided with a discharge port 5, the steel wire enters the inside of the furnace body 2 through the feed port 4, and then stretches out through the discharge port 5; the inside of the furnace body 2 A tempering mechanism 6 is provided, a limiting mechanism 7 is provided on the outside of the furnace body 2 and outside the discharge port 5, and a longitudinal cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com