Hollow microsphere three-dimensional matrix layer door and window frame with heat insulation, sound insulation, self-cleaning, sterilization and air cleaning functions

A three-dimensional matrix, heat and sound insulation technology, applied in the direction of sound insulation door/window, window/door frame, door/window application, etc. The effect of the hot and cold bridge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

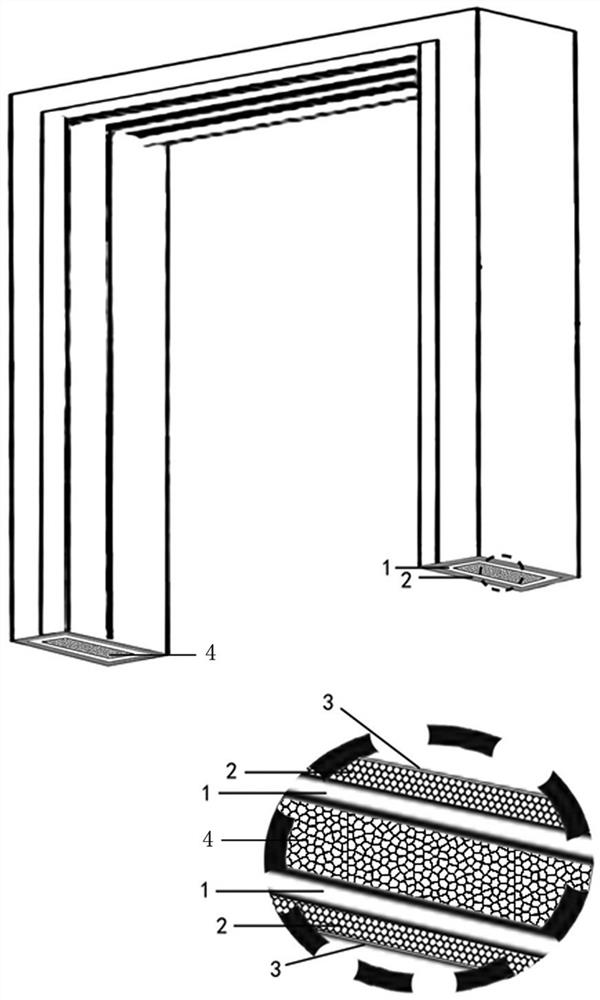

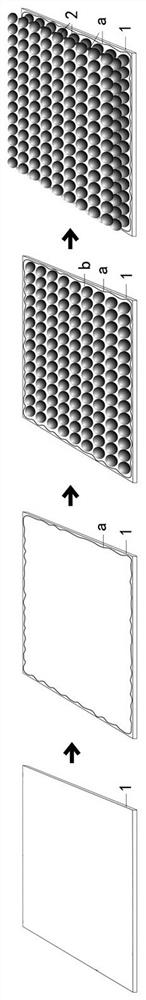

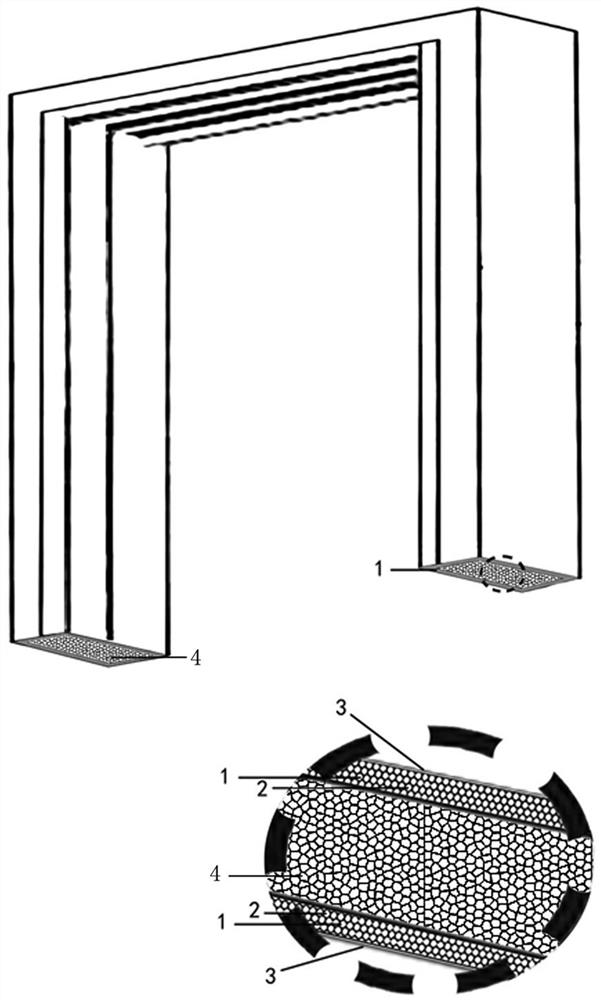

[0014] exist figure 1 Among them, the inner and outer surfaces of the metal door and window frame edge 1 are each coated with a 0.3 mm three-dimensional matrix layer of hollow microbeads 2 using the "hollow microbead matrix layer sticky coating method" invented by myself. The bead matrix layer is made of ceramic hollow microbeads with a diameter of 200-600 nanometers, which are coated on the outer layer of the door and window frame by the adhesive coating method. The anti-radiation film 3 is nano-scale red gold titanium dioxide. The heat insulation core 4 is filled in the door and window frame edge 1 . Here the heat insulation core 4 is non-combustible phenolic foam filled in situ. Phenolic foam is filled in the door and window frame and bonded together with the door and window frame, which greatly improves the strength of the door and window frame or can reduce the thickness of the door and window frame. In summer, the hollow microbeads three-dimensional matrix layer door ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com