A fast-charging continuous operation coal pipeline cleaning and dredging robot

A technology for conveying pipelines and fast charging, which is applied to current collectors, machines/engines, and tube components, etc., can solve the problems of increased transportation resistance, increased transportation resistance, and the inability to ensure long-distance and long-term continuous operation of pipeline cleaning robots. Achieve the effect of improving work reliability and cleaning thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

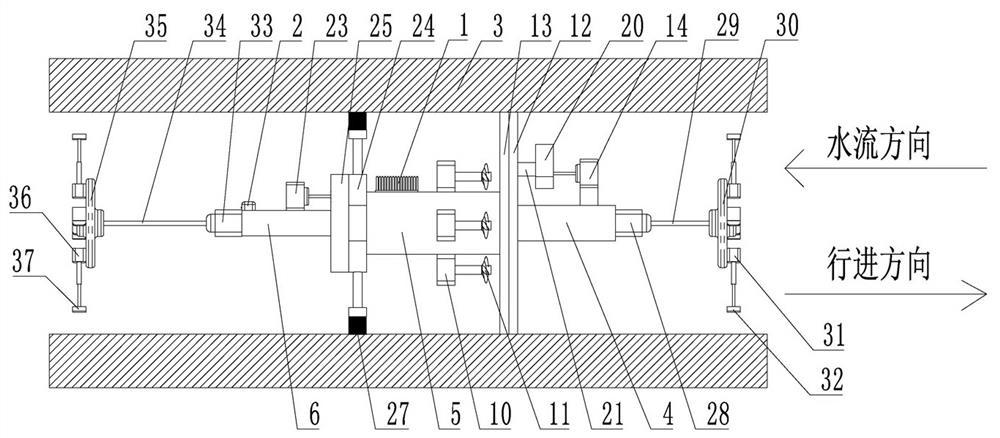

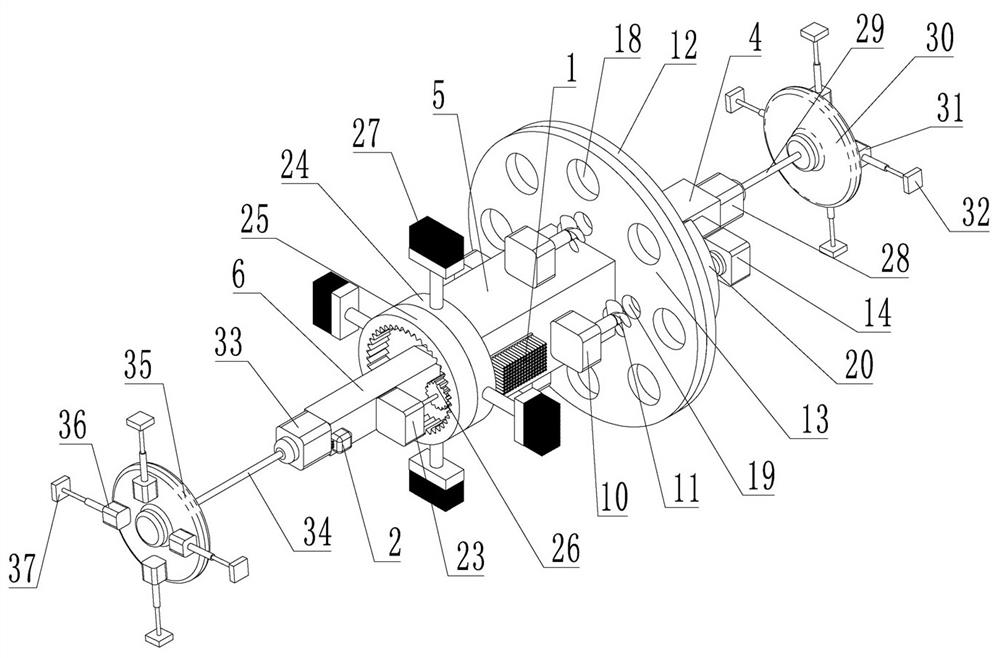

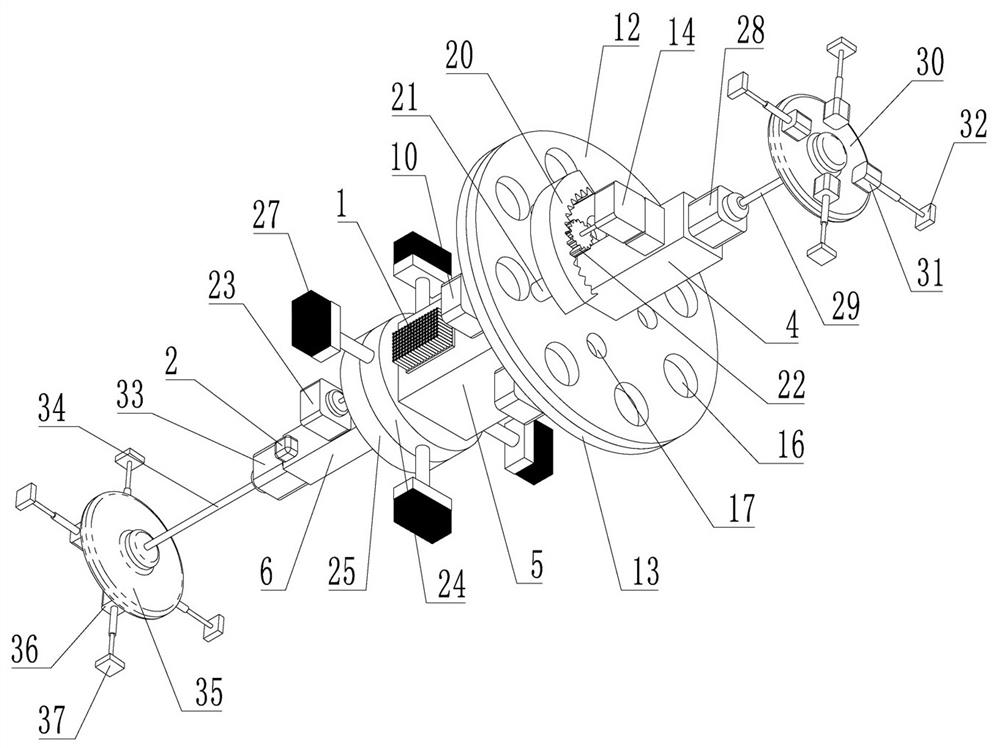

[0029] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0030] by figure 1 The middle right is the front side.

[0031] Such as Figure 1-Figure 9 As shown, a fast-charging continuous operation coal conveying pipeline cleaning and dredging robot includes a main body, a battery pack 1, a power generating device, a charging state switching device, a cleaning device and a PLC controller 2. The main body is a cuboid prism structure, and the length direction of the main body is along the The front and rear directions are arranged horizontally, the body is concentrically arranged in the coal delivery pipeline 3, the front end of the coal delivery pipeline 3 is connected to the water source through a water pump, the water in the coal delivery pipeline 3 flows from front to back, and the battery pack 1 and the PLC controller 2 are fixedly installed On the main body, the exterior of the battery pack 1 and the PLC co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com