Sewage analysis and assessment system for supervision

A sewage analysis and supervision technology, applied in the direction of analysis materials, test water, cleaning methods and utensils, etc., can solve the problem of low detection accuracy of sampled sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

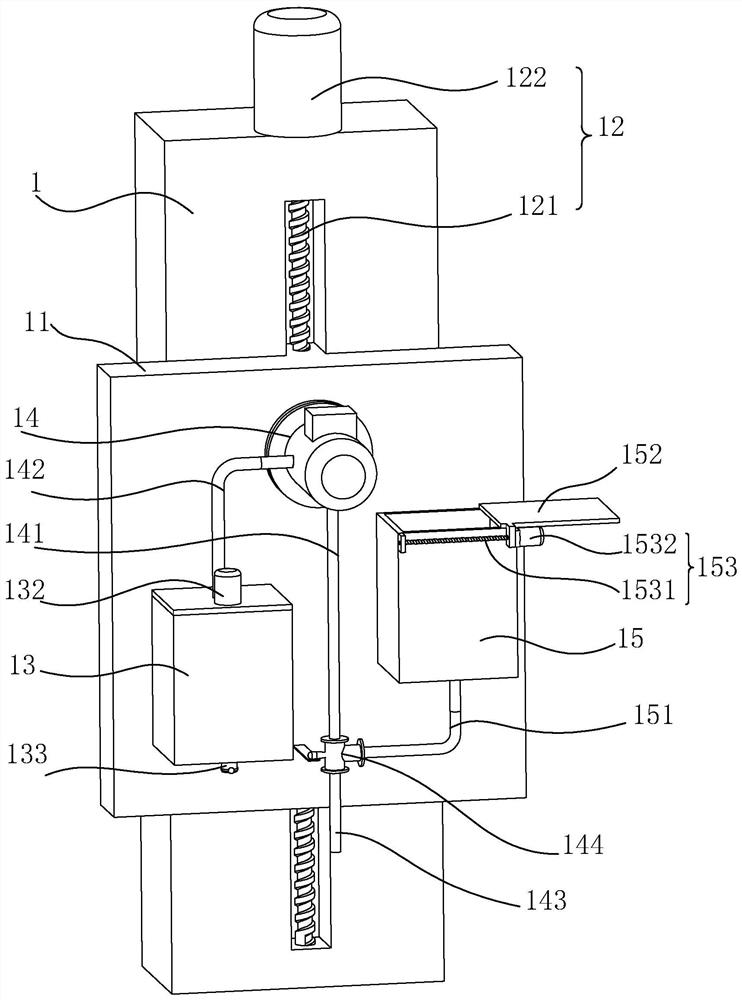

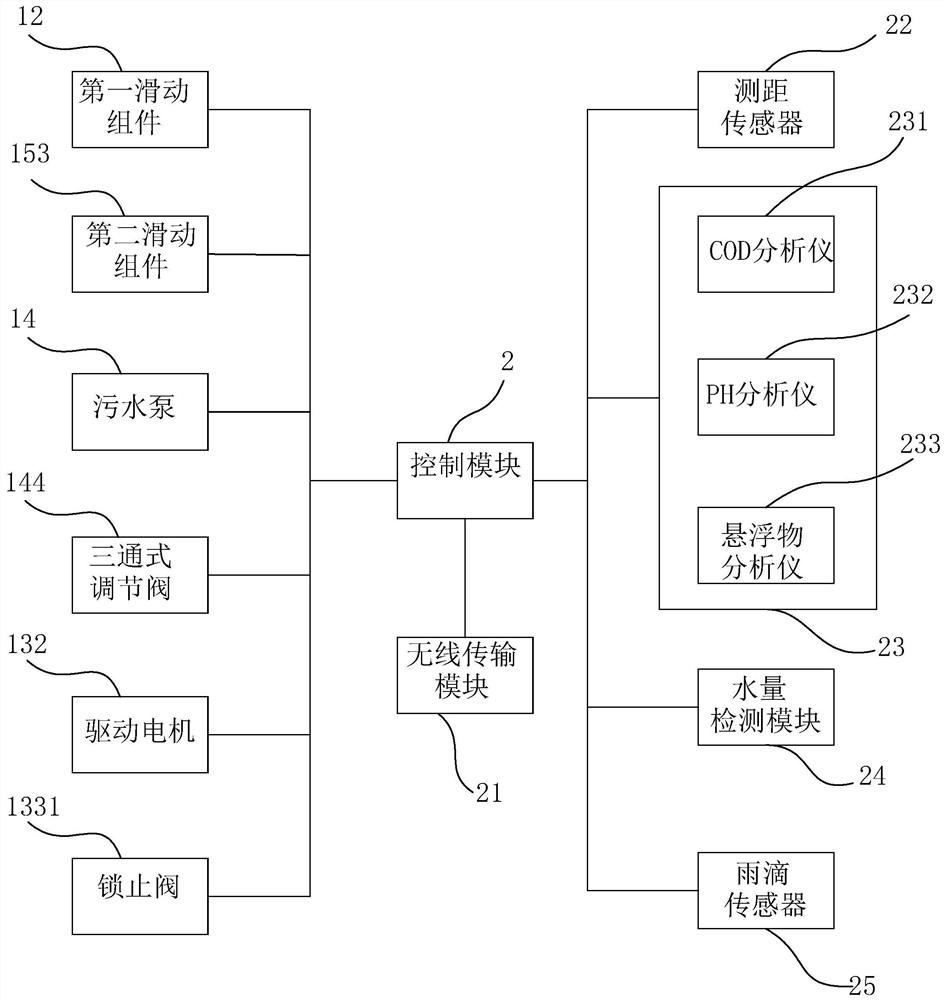

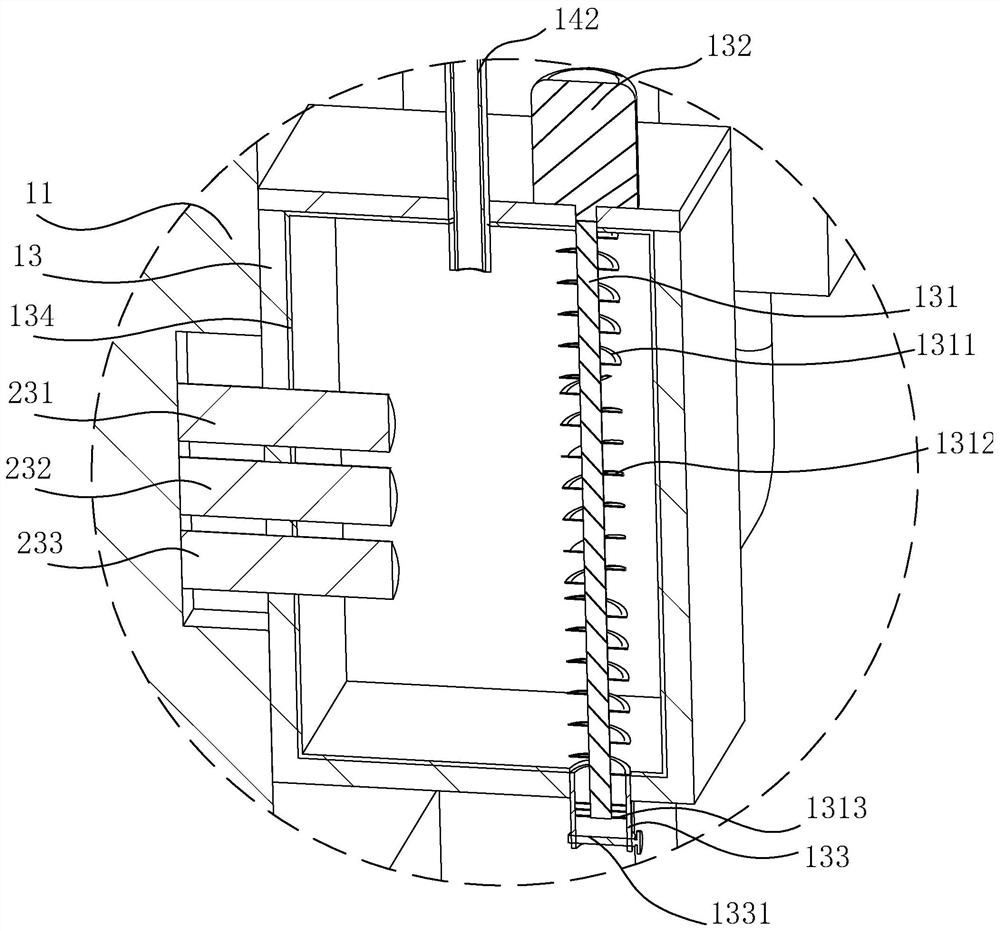

[0033] The following is attached Figure 1-3 The application is described in further detail.

[0034] The embodiment of the application discloses a sewage analysis and assessment system for supervision. refer to figure 1 and figure 2 The sewage analysis and assessment system includes a sampling box 13 for collecting sewage and a sewage pump 14 for pumping sewage in the sewage channel to the sampling box 13. A detection unit 23 for detecting the quality of sewage is fixedly installed inside the sampling box 13. Detection unit 23 comprises COD analyzer 231, PH analyzer 232 and suspended matter analyzer 233; The data output end of detection unit 23 is electrically connected with control module 2, and control module 2 can be the PLC controller that Siemens produces; Control module 2 Electrically connected with a wireless transmission module 21 for remotely transmitting the detection data to a mobile terminal or a computer terminal, the wireless transmission module 21 may be a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com