A laminated coil component

A coil component, laminated technology, applied to transformer/inductor parts, electrical components, transformer/inductor coils/windings/connections, etc., can solve the problems of installation and high frequency characteristics, insufficient characteristics, stray Capacitance and other problems, to achieve excellent results in mountability and high-frequency characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, the laminated coil component of the present invention will be described.

[0025] However, this invention is not limited to the following embodiment, It can change suitably and apply in the range which does not change the summary of this invention. In addition, it is also the invention that combines two or more of the respective preferred structures described below.

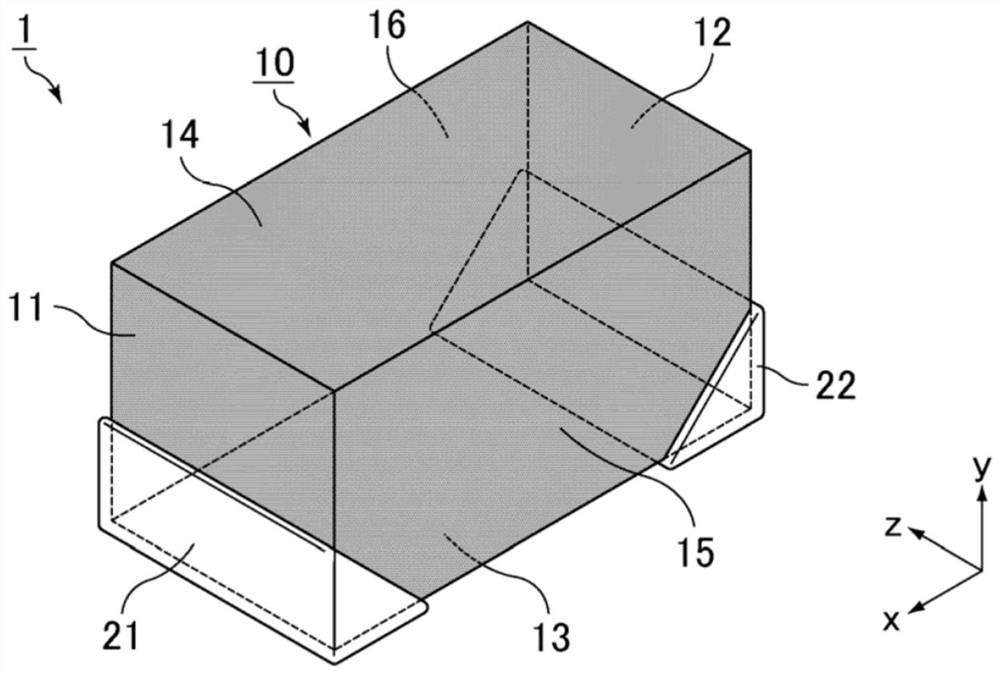

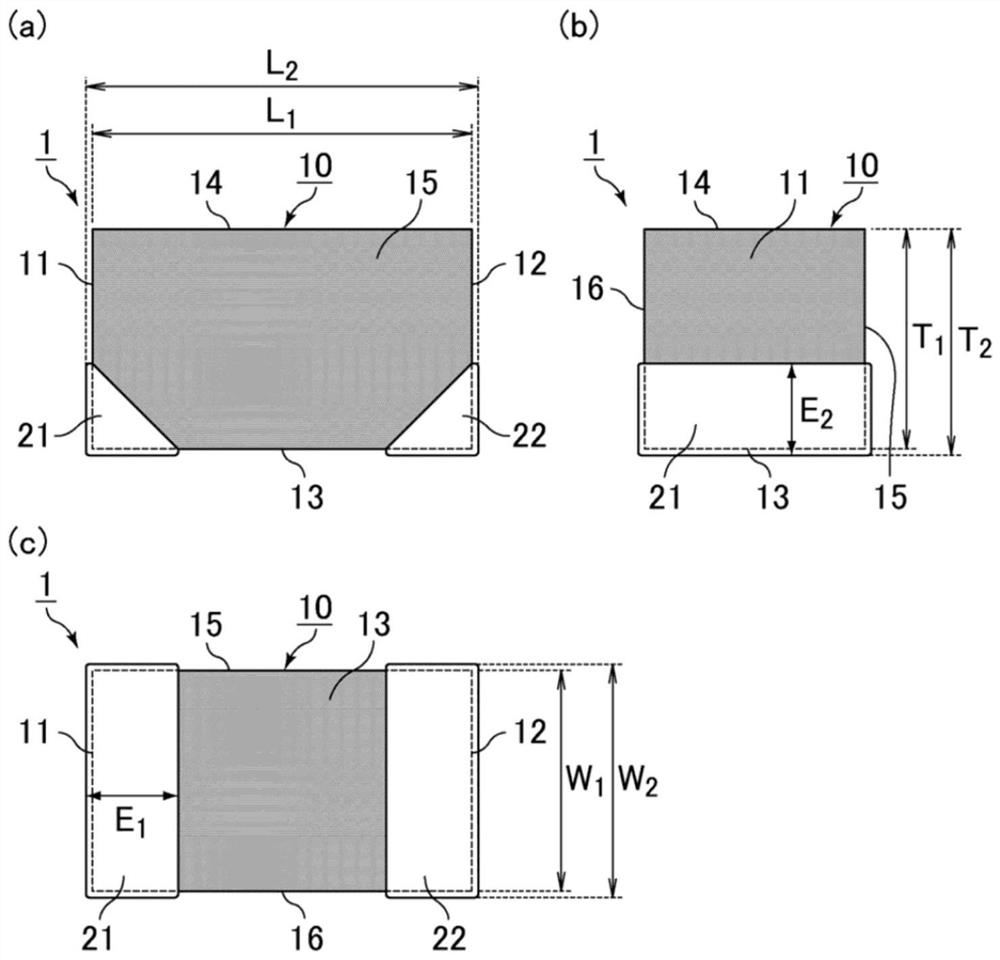

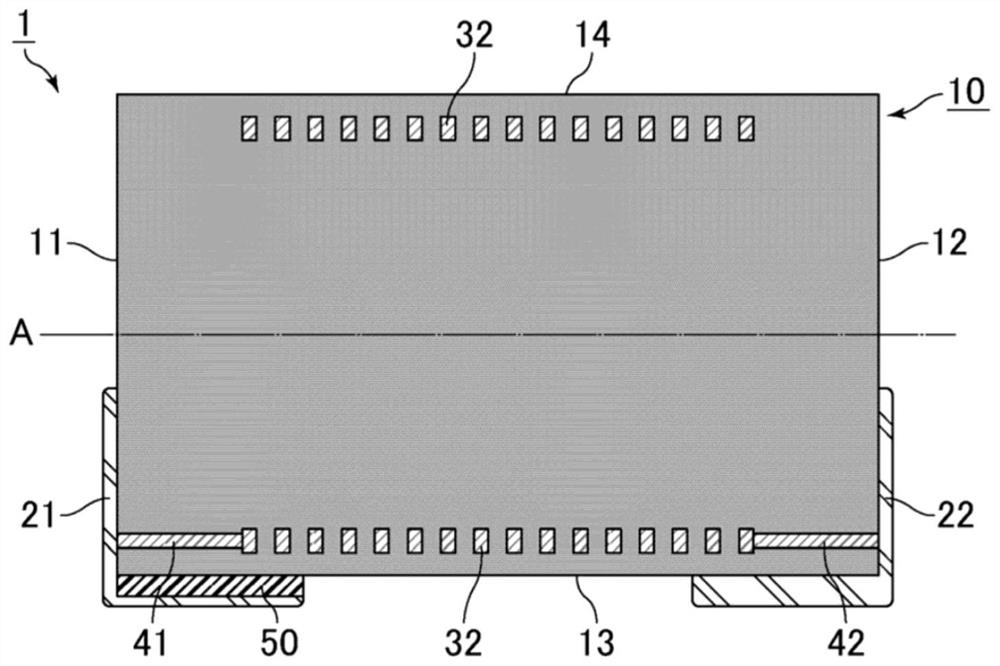

[0026] figure 1 It is a perspective view schematically showing an example of the laminated coil component of the present invention. figure 2 (a) is figure 1 A side view of the laminated coil assembly shown, figure 2 (b) is figure 1 The front view of the laminated coil part shown, figure 2 (c) is figure 1 Bottom view of the laminated coil component shown.

[0027] figure 1 , figure 2 of (a), figure 2 (b) of and figure 2 The laminated coil component 1 shown in (c) includes a laminated body 10 , a first external electrode 21 , and a second external electrode 22 . The laminated b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com