Hawthorn wine fermentation preparation wastewater treatment device

A technology for wastewater treatment and hawthorn wine, which is applied in the directions of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of affecting the water flow rate at the filter place, easy clogging of hawthorn waste residue, waste of human resources, etc., to avoid waste of human resources, The effect of reducing the number of cleanings and ensuring the discharge speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

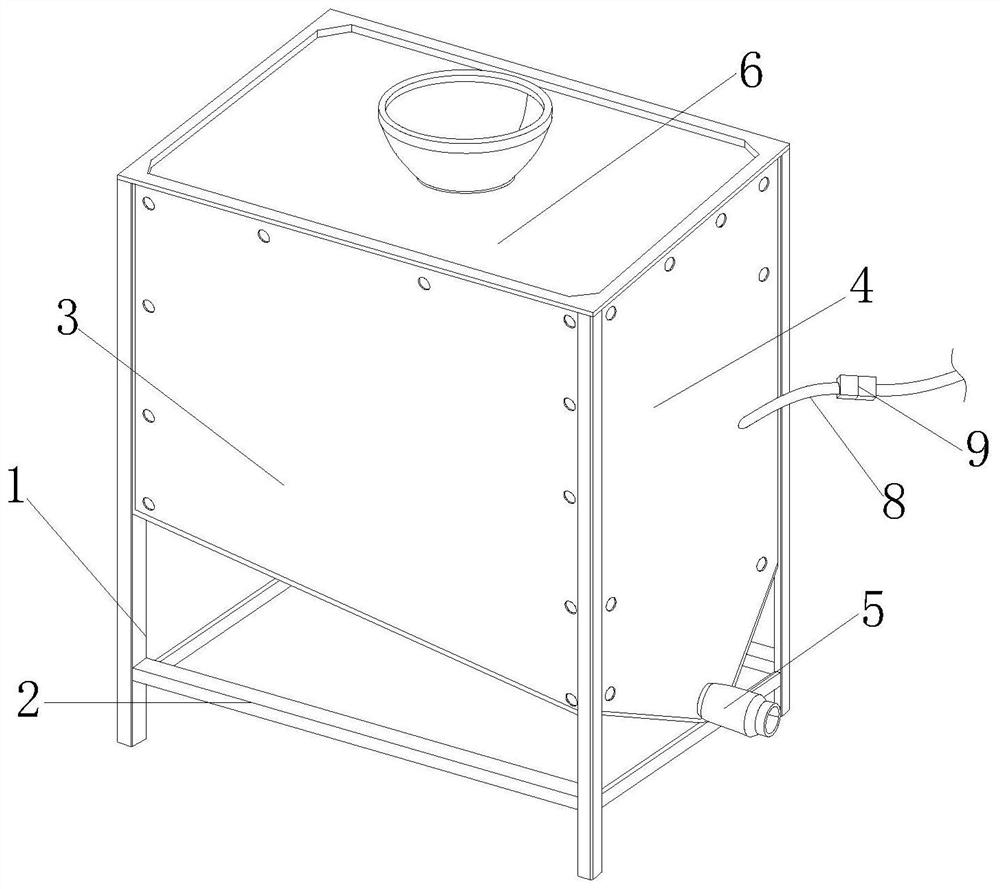

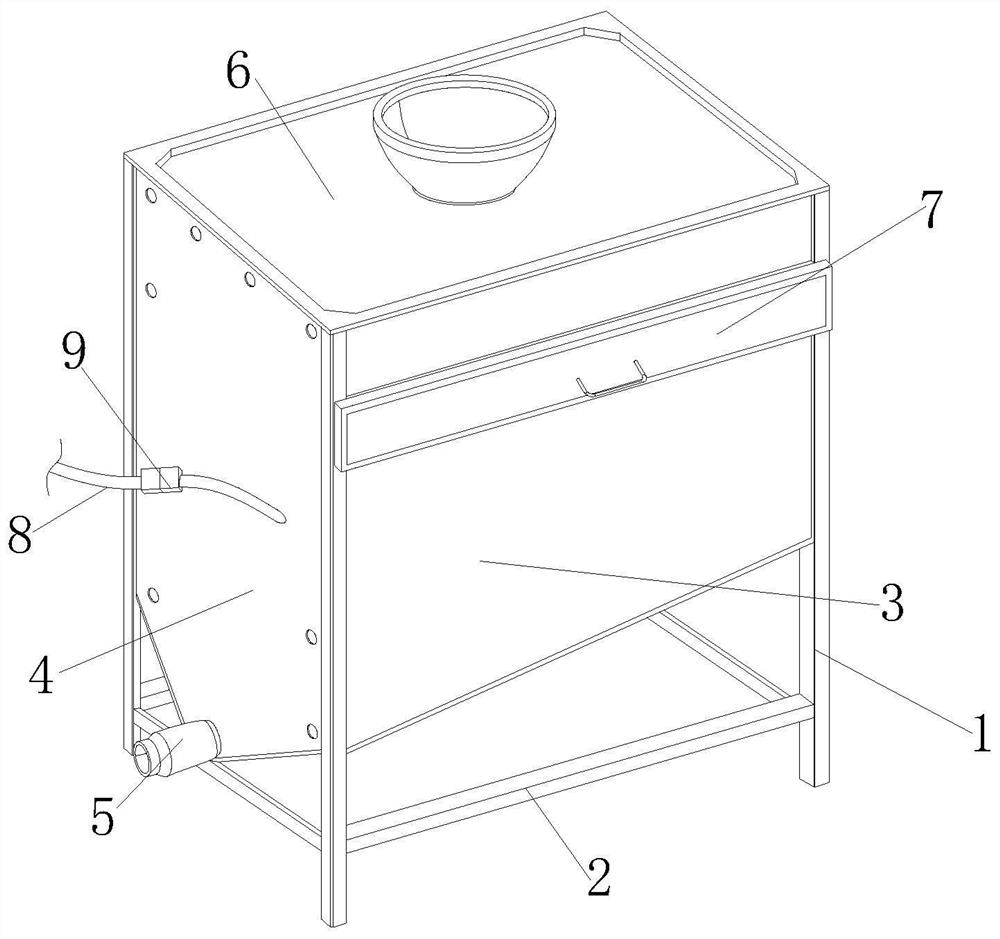

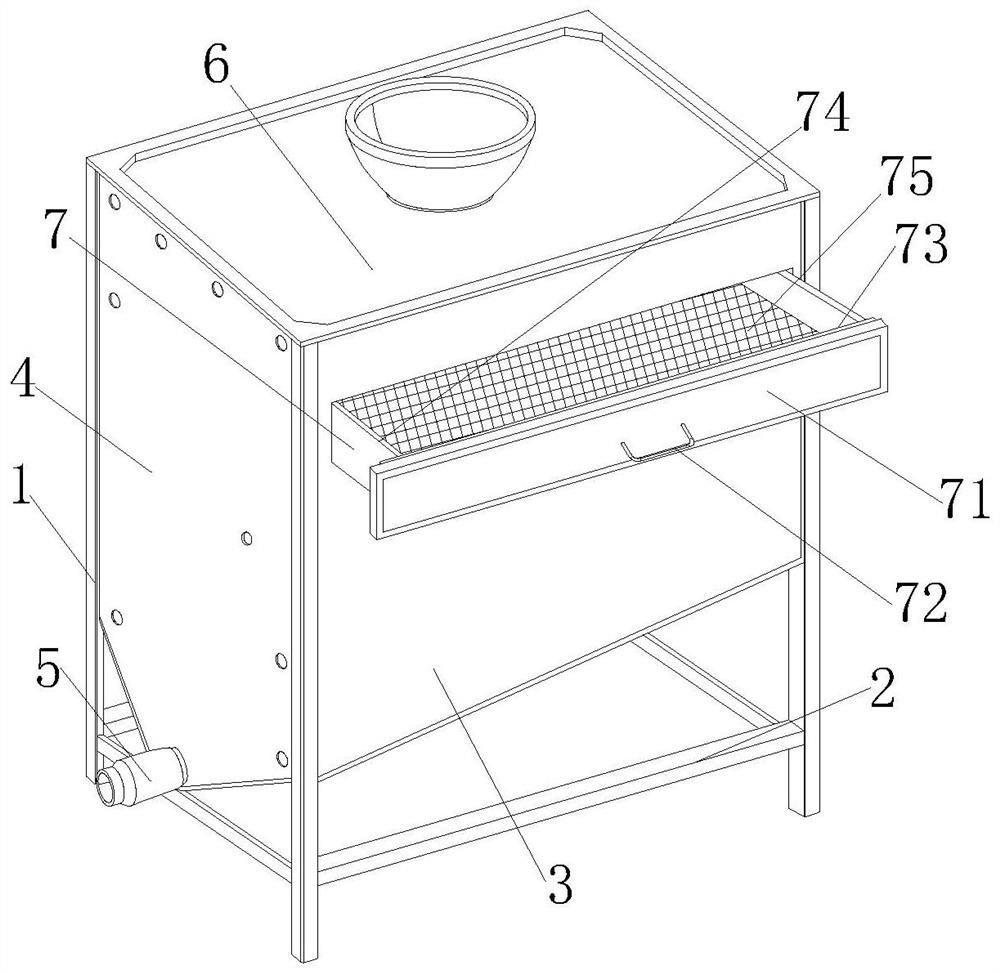

[0030] See figure 1 with figure 2 , A hawthorn wine fermentation preparation wastewater treatment device of the present invention includes a support 1, a cross-bar frame 2, a guard plate 3, a side plate 4, a drain valve 5, a residue filter mechanism 6, a preliminary filter structure 7, a power cord 8 and Control switch 9. Four cross-bar racks 2 are fixed horizontally on the inner bottom side of the support 1, the top of the front and back sides of the support 1 are vertically fixed with guard plates 3, and the side plates 4 are fixedly connected to the left and right sides of the support 1. 1 The drain valve 5 is embedded transversely at the bottom of the right side plate 4, the power cord 8 is arranged in the middle of the right side plate 4 of the support 1, the control switch 9 is installed inside the power cord 8, and the residue filter mechanism 6 is fixedly connected to the guard plate 3 and inside the side plate 4, the top side of the residue filter mechanism 6 is slidin...

Embodiment 2

[0036] In a hawthorn wine fermentation preparation wastewater treatment device of the present invention, the support block 63 is in a triangular shape, and the top of the support block 63 is slidingly fitted back and forth with the primary filter structure 7 to facilitate the support of the primary filter structure 7, the driving bevel gear 6512 and the driven The size of the bevel gear 6513 is the same, and the angle between the driving bevel gear 6512 and the driven bevel gear 6513 is 90 degrees, which facilitates steering transmission. The first rack 6522 and the second rack 6523 have the same structure size, and The first rack 6522 and the second rack 6523 are symmetrically arranged in the middle of the half gear 6521 to facilitate up and down intermittent movement through cooperation with the half gear 6521. The right side of the sliding block 6526 is inserted into the groove on the right side of the frame seat 61. In addition, the sliding block 6526 slides up and down in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com