Environment-friendly varnish baking device for furniture production

A kind of baking paint, environmental protection technology, applied in the field of furniture baking paint, can solve the problems of poor environmental protection, irritating odor, fixed baking paint, etc., to achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

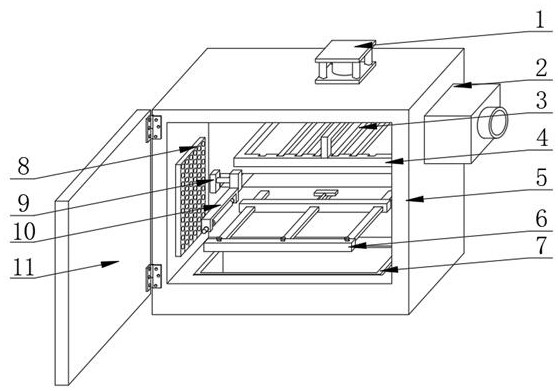

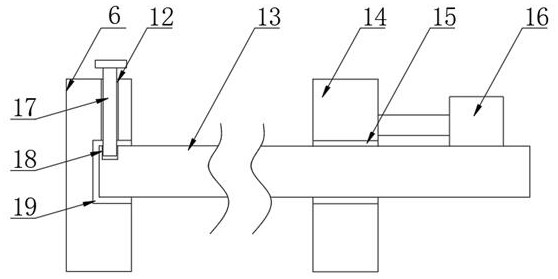

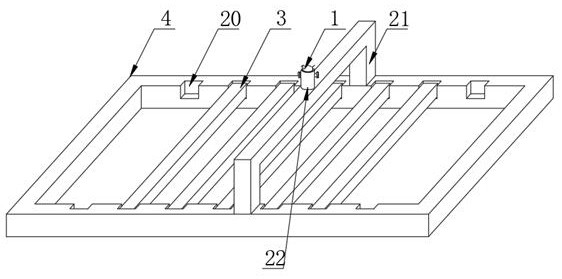

[0028] see Figure 1~5 , in the embodiment of the present invention, an environment-friendly paint baking device for furniture production includes a paint baking box 5, a fixing plate 6 is arranged inside the paint baking box 5, a through hole 12 is opened inside the fixing plate 6, and the fixing plate 6 One side is provided with a mounting groove 19, and the inside of the mounting groove 19 is penetrated with a placement rod 13, and the upper surface of the mounting groove 19 is provided with a screw hole 18, and the upper surface of the fixing plate 6 is provided with a fastening bolt 17 and the fastening bolt 17 One end of one end extends through the inside of the through hole 12 to the inside of the screw hole 18 and is threadedly connected with the screw hole 18, and the fixing plate 6 is fixed by the fastening bolt 17, so that the fixing plate 6 can be quickly installed and disassembled conveniently; The outside is slidingly equipped with a moving plate 14, and the insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com