Self-service cargo loading and unloading turnover system

A turnover system and cargo technology, applied in the direction of loading/unloading, lifting devices, transportation and packaging, etc., can solve the problems of low efficiency, high cost, and the inability of deep integration of road transportation and railway transportation, so as to improve the safety factor and reduce the The effect of handling, saving labor costs and site space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The working principle of the cargo self-service loading and unloading turnover system will be described below in conjunction with the embodiments given in the accompanying drawings.

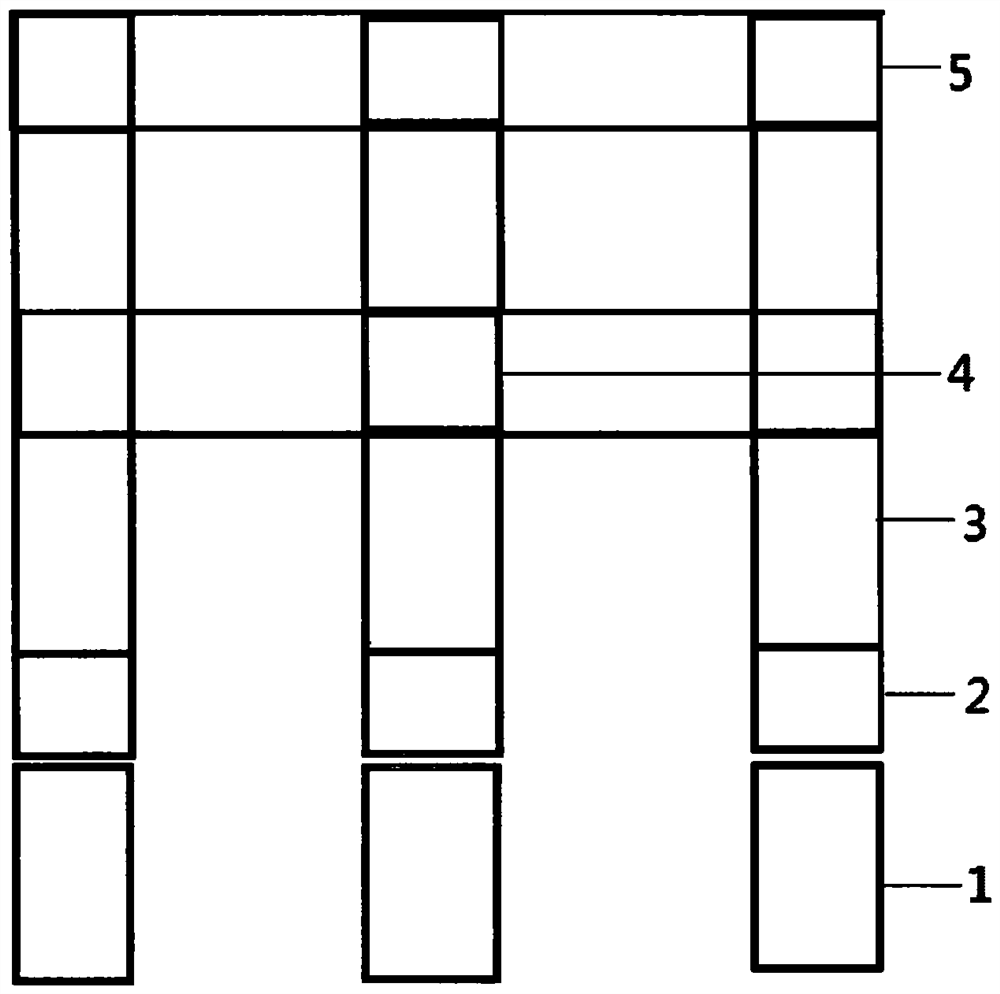

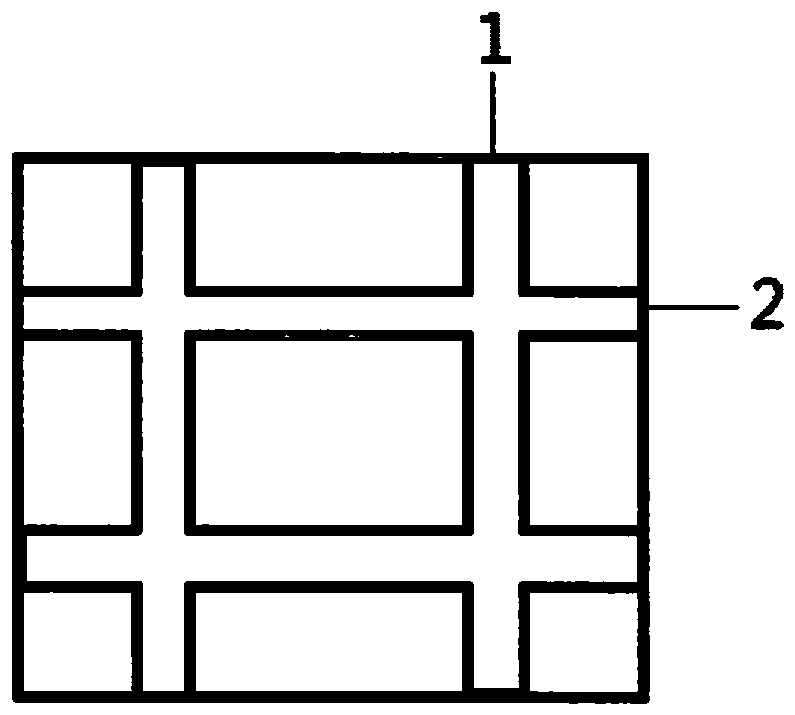

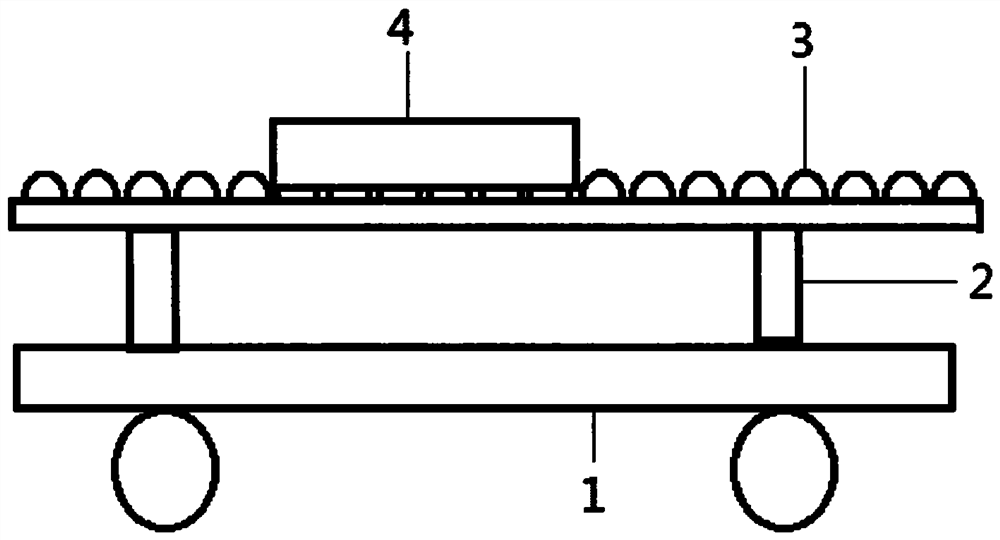

[0024] Such as figure 1 As shown, first pass the car lifting platform ( figure 1 The displacement of middle 1) makes the vehicle lifting platform ( figure 1 1) backend and docking platform ( figure 1 In 2), align the front ends in parallel longitudinally, and then open the car tray ( image 3 1) in the fixing device, and then through the lifting platform ( image 3 Middle 2) and lifting platform ( Figure 4 Middle 4) moves up and down, making the power track ( image 3 Middle 3) and power track ( Figure 4 Middle 2) docking, while making the multifunctional container ( image 3 Middle 4) Detach from the car tray ( image 3 1) in the fixture, and then open the power track ( image 3 Middle 3), in the power track ( image 3 Middle 3) and sliding groove ( figure 2 Under the combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com