Segmented reinforcement cage and continuous wall construction method under low-clear-air high-voltage line

A technology of underground diaphragm wall and steel cage, which is applied in the direction of sheet pile wall, foundation structure engineering, construction material processing, etc., to achieve the effect of convenient hoisting, simple and convenient connection, and simple and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

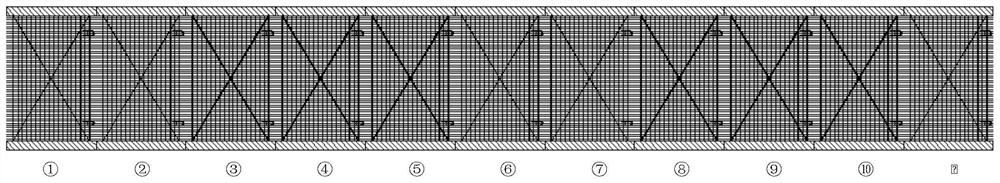

[0060] This embodiment takes a section of a certain river tunnel as an example. The construction area of the underground diaphragm wall in this embodiment belongs to the joint construction section of rail transit and road, and the overhead line above the construction area is a 110KV high-voltage line crossing the road, located at EK0+870 of the joint construction section ~EK0+900 section.

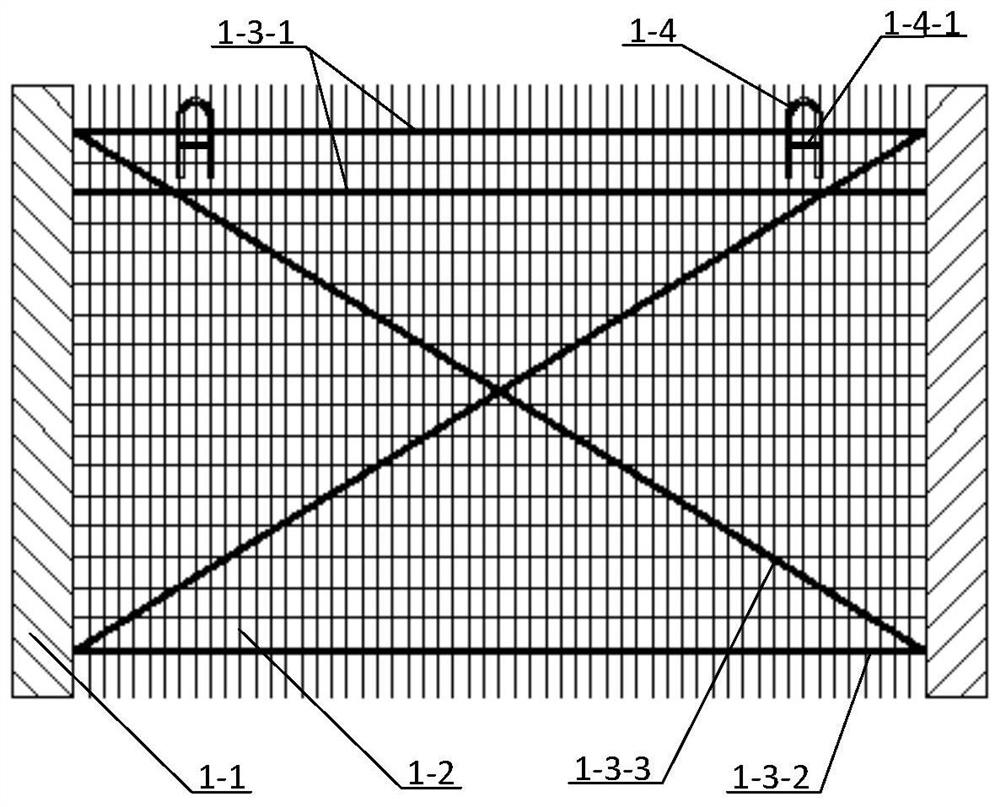

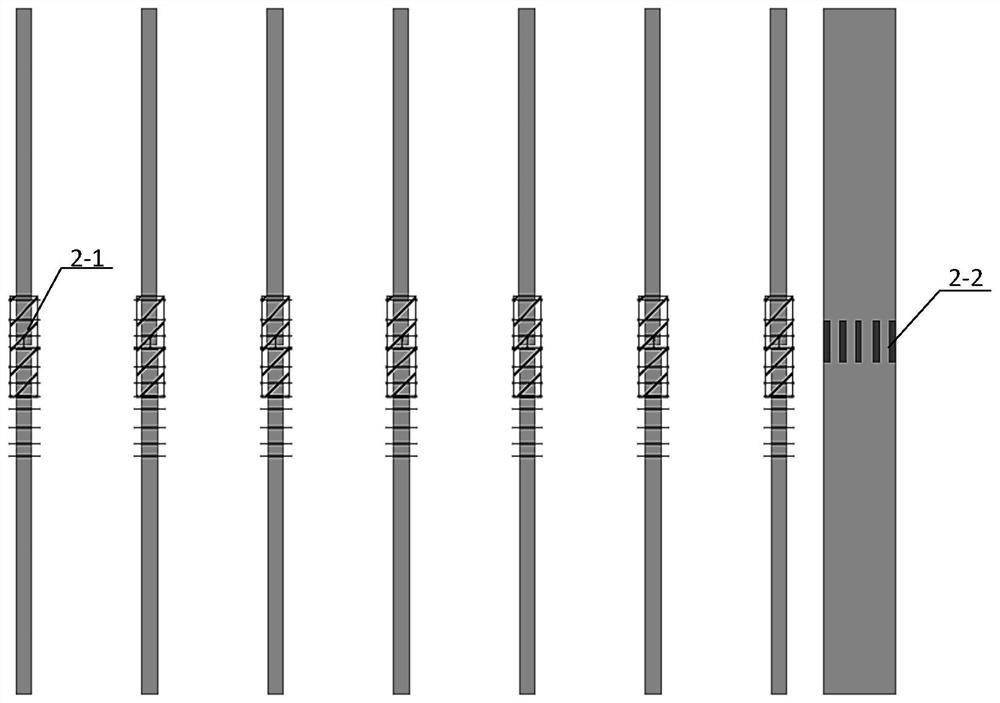

[0061] In the present embodiment, the sectioned reinforcement cage for the continuous wall is adopted, including: a multi-section reinforcement cage unit 1, and the reinforcement cage unit 1 is as figure 1 As shown, it includes reinforcement cage skeleton 1-1, main reinforcement 1-2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com