A method for continuous recovery of residual top and bottom pillars using large sections

A large-section, top-bottom technology, applied in ground mining, mining equipment, earthwork drilling, etc., can solve the problems of waste of resources, difficult construction, shelving of resources, etc., to avoid low efficiency, save mining costs, and reduce resource losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

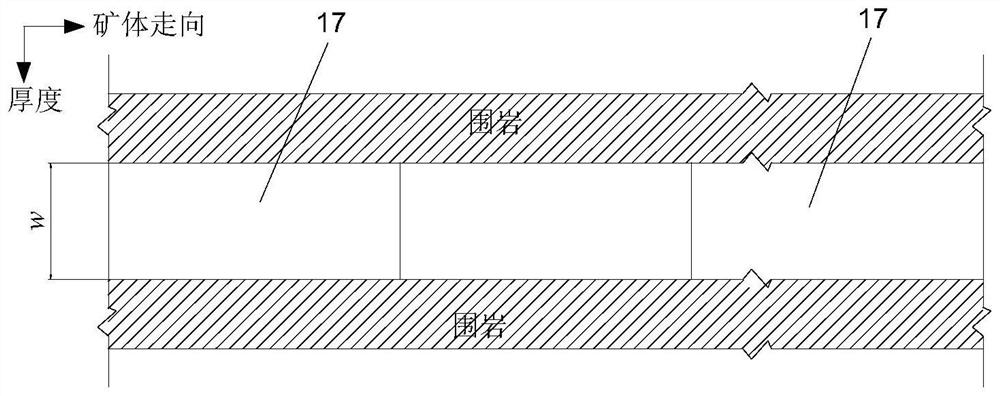

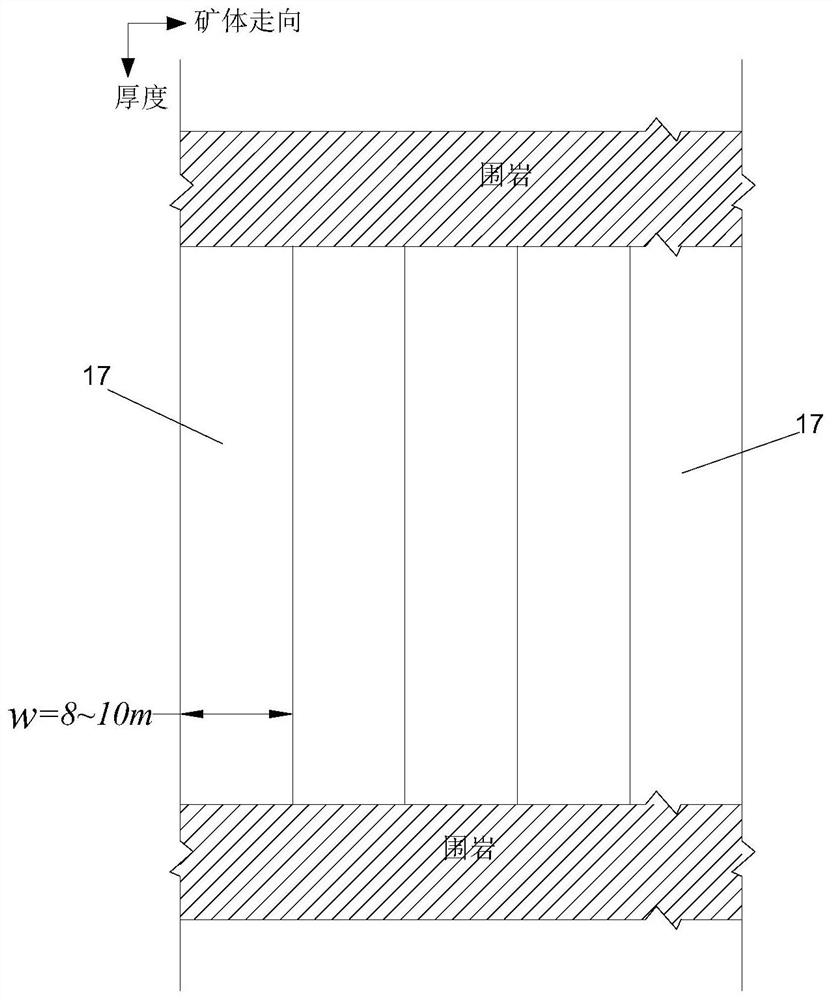

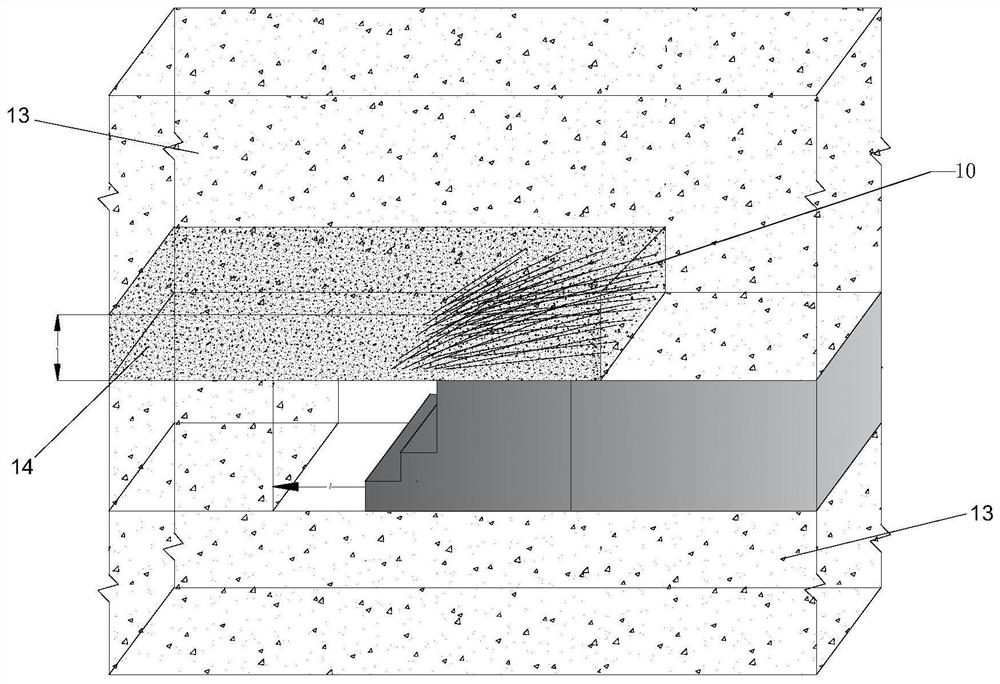

[0091] The design method of the present invention will be further described in conjunction with the back mining of the 15 top pillars of the 612 mine house stope in the middle section of Guangxi Panlong lead-zinc mine-170. This lead-zinc mine adopts the mining method of stage emptying and then filling, and a large number of top and bottom pillars are left in each middle section. In order to fully recover resources, the method of recovering top and bottom pillars with large cross-sections has been applied. Among them, the height of the 15 top pillars in the stope of the 612 mine is 8m, the dip angle of the ore body is 79°~88°, the average dip angle is 83.5°, the average thickness of the ore body is 8m, and the ore integrity coefficient is 0.75, which belongs to relatively complete rock. 15 and the stope 16 of mine house 512 in the upper middle section are all filled with cement, and the relevant physical and mechanical parameters are shown in Table 1.

[0092] Table 1

[0093] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com