Explosion suppression system and method applied to steel converter gas recovery

A steel-making converter and converter gas technology, which is applied in the manufacture of converters, measuring devices, instruments, etc., can solve problems such as endangering the safety of converter equipment and production personnel, reduce energy consumption, reduce sewage discharge, and ensure safe recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

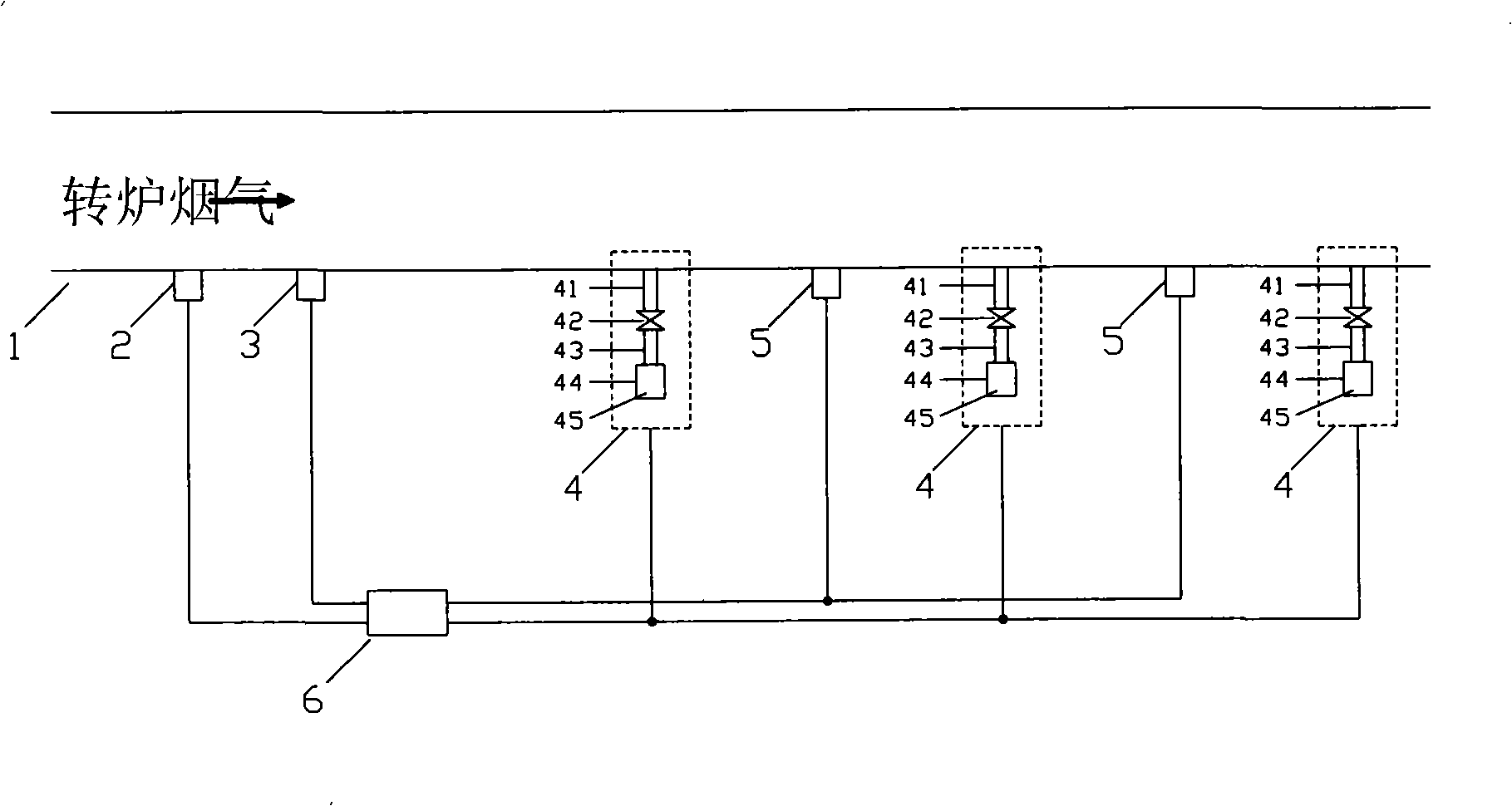

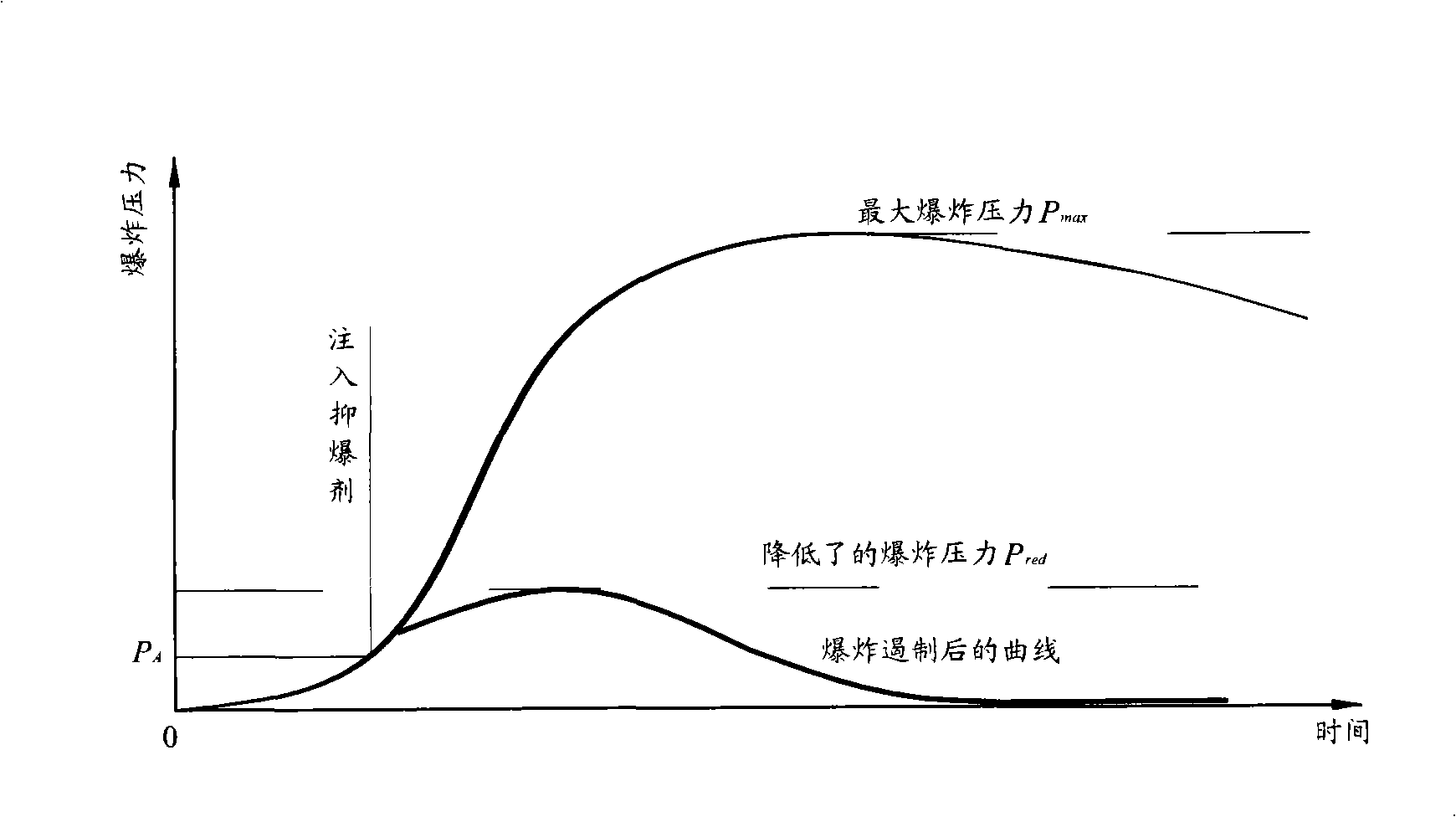

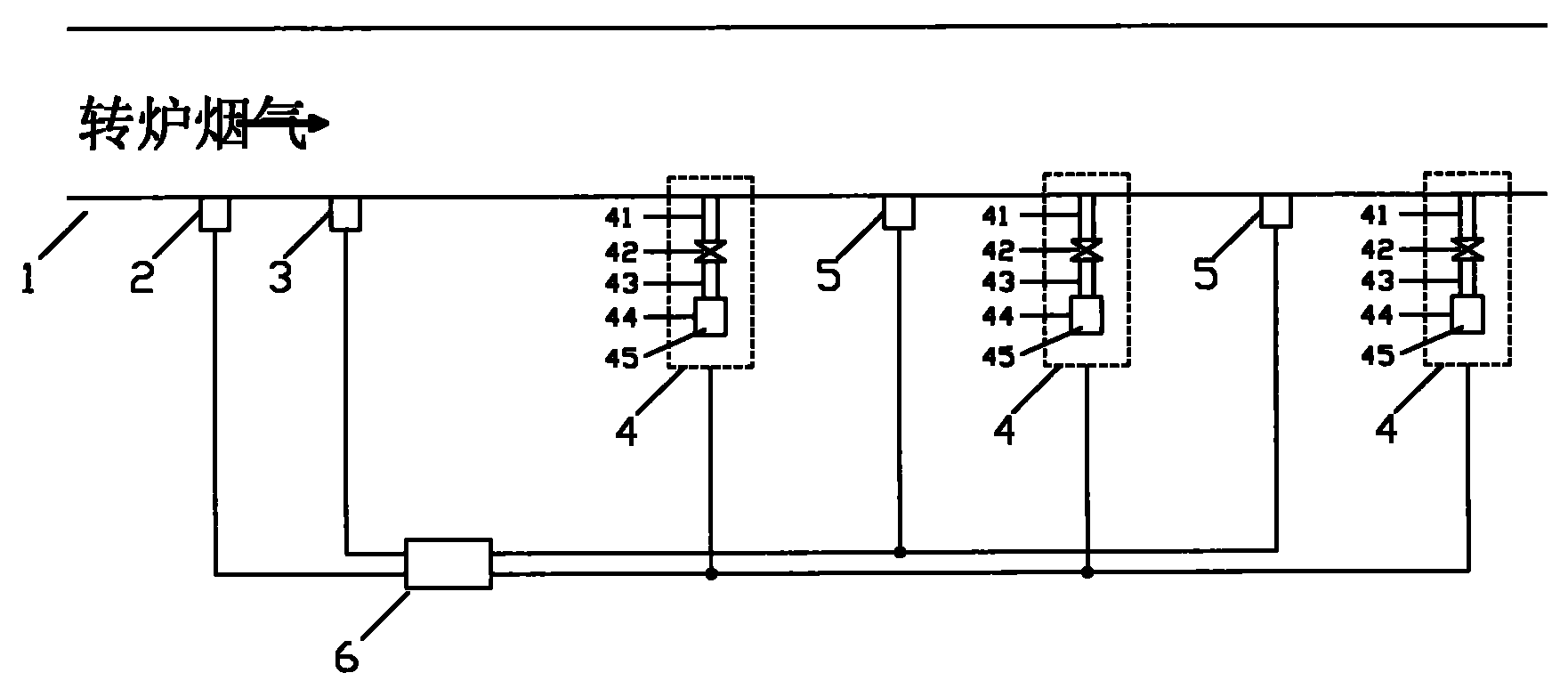

[0020] Such as figure 1 As shown, the embodiment of the present invention provides an explosion containment system applied to steelmaking converter gas recovery, the system includes: on the wall surface of the converter gas pipeline 1, a gas detector 2, an explosion detector 3, a suppression Explosion device 4, explosion relief valve 5, gas detector 2 and explosion detector 3 are installed upstream of converter gas pipeline 1, and gas detector 2 is used for real-time detection of CO and O 2 The ratio in the flue gas, the explosion detector 3 is used to monitor the pressure in the converter gas pipeline 1, wherein the explosion detector 3 is a photosensitive sensor and / or a pressure sensor, and the explosion suppressor 4 is started by the explosion suppressant nozzle 41, Valve 42, antiknock agent pipeline 43, antiknock agent storage tank 44 and antiknock agent 45 are formed, one end of the antiknock agent spout 41 is connected with the antiknock agent storage tank 44 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com