Multi-robot monitoring method suitable for production line operation

A multi-robot and production line technology, applied in the direction of instruments, computer components, data processing applications, etc., can solve the problems of small positioning range, complex structure, inconvenient promotion and use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0075] A kind of multi-robot monitoring method suitable for production line operation of the present invention is specifically implemented according to the following steps:

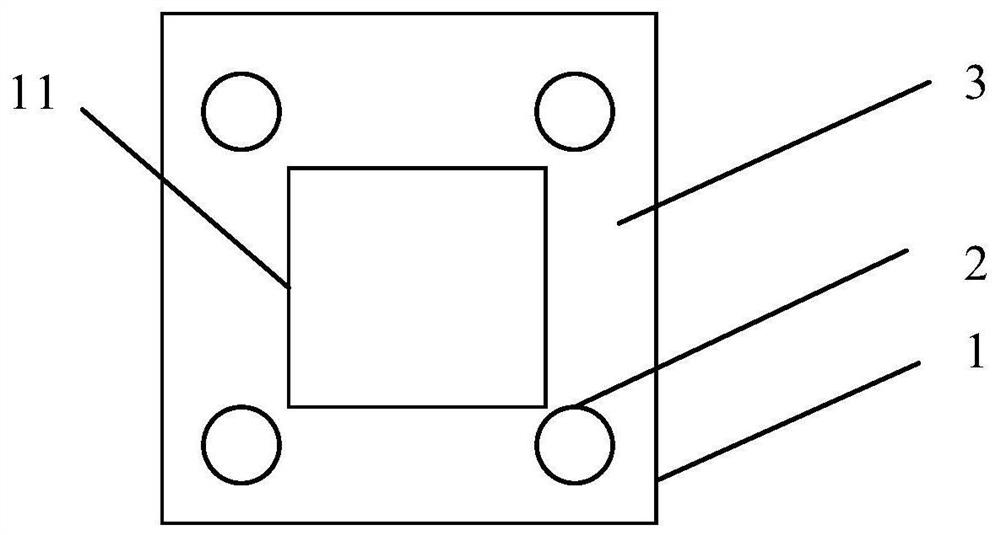

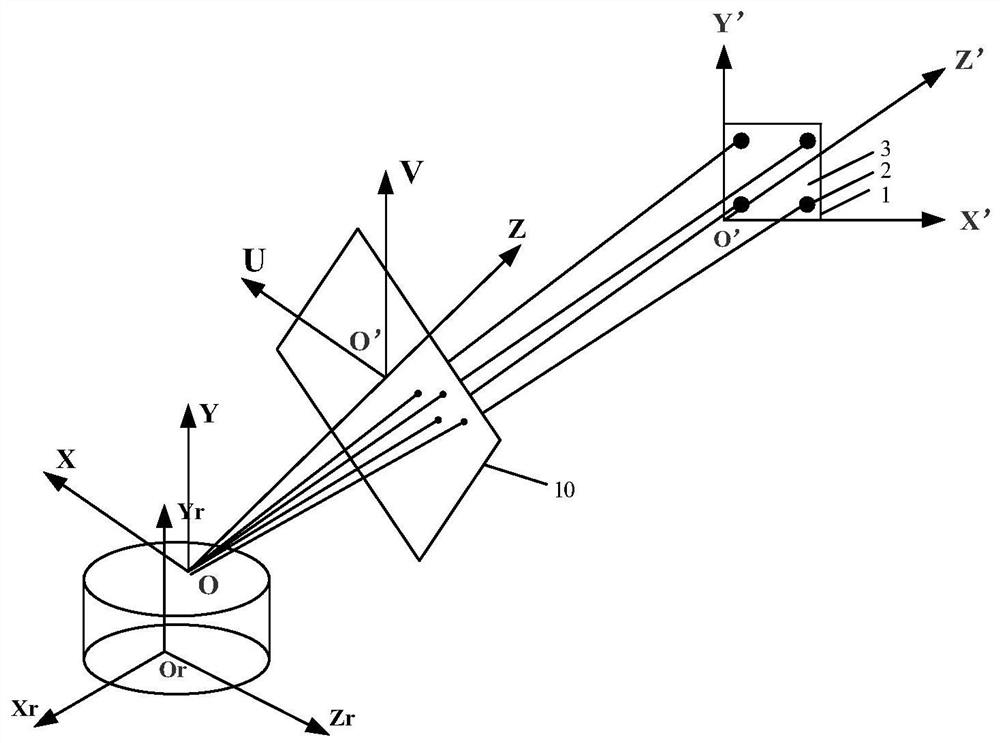

[0076] Step 1, utilize target, computer 8, wireless transceiver 9, two-dimensional turntable 6, CCD camera 5 to construct a multi-robot monitoring system; The target that the present invention adopts, target size is 40*40mm, and its structure is as follows figure 1 As shown, a cube-shaped housing 1 is included, and a drive circuit 3 is arranged inside the housing 1. Four positioning light spots 2 of the same size are arranged on the working surface on the outer wall of the housing, and the positioning light spots 2 are all infrared LED, 4 positioning light spots 2 arranged in a square;

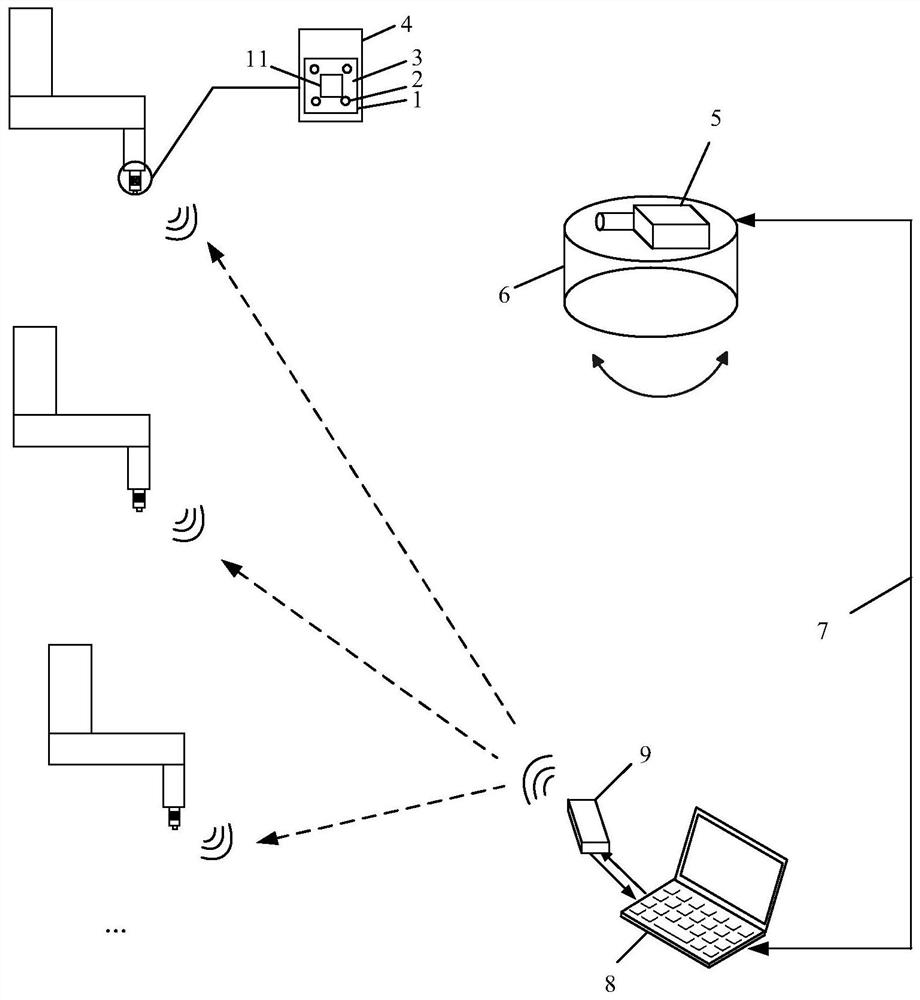

[0077] like figure 2 As shown, the multi-robot monitoring system includes a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com