Industrial camera for electric welding monitoring

An industrial camera and camera technology, which is applied to color TV parts, TV system parts, TVs, etc., can solve the problems that the filtering range has an upper limit, it is difficult to achieve strong light suppression, and achieve simplified algorithms and hardware requirements. Reduced processor and other hardware requirements, easy to implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with embodiment.

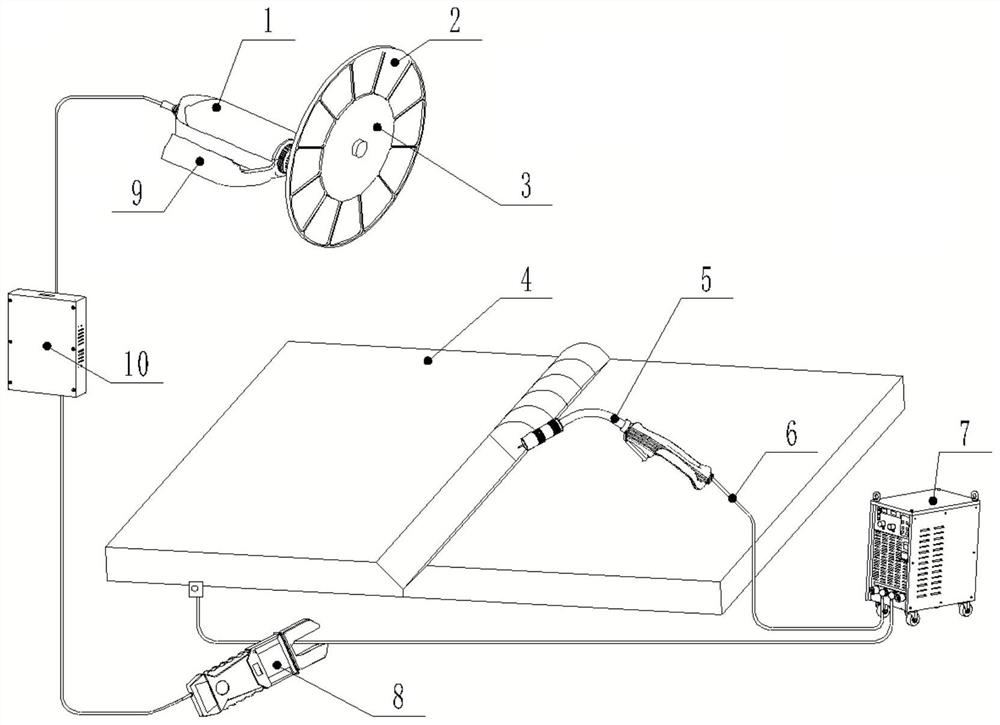

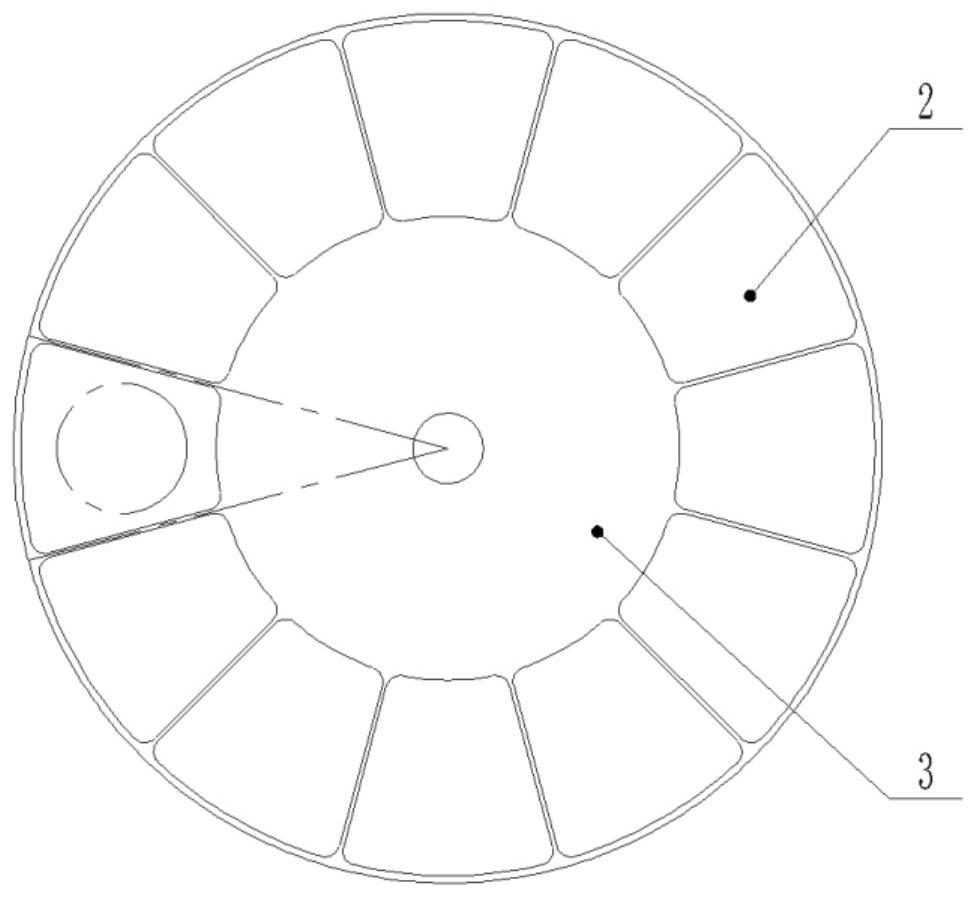

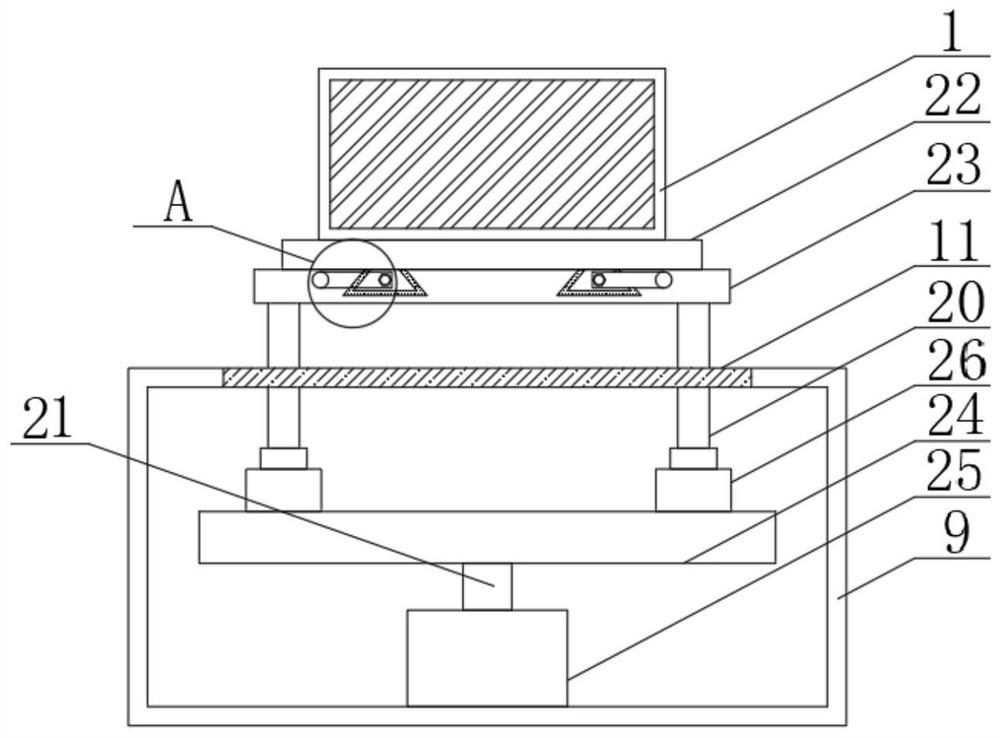

[0039] Such as Figure 1-2 As shown, an industrial camera for electric welding monitoring includes a camera 1, a filter disc 3 installed at the front end of the camera 1, a control box 10 and a camera adjustment box 9, and the filter disc 3 is provided with a plurality of filters with different concentrations Optical sheet 2, optical filter 2 is arranged in the circumferential direction of the outer edge of filter disc 3, optical filter 2 coincides with or is parallel to the optical path of the lens of camera 1, and the camera can pass through the optical filter to take images during electric welding, and said filter disc 3 Rotatable, only one optical filter 2 coincides with the lens optical path of the camera 1 at any time;

[0040] The control box 10 measures the current generated when the electric welding equipment works, and controls the rotation of the filter disc 3 in real tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com