Drivetrain unit for a hybrid vehicle having axial compensation

A transmission system and motor vehicle technology, applied in hybrid vehicles, vehicle subunit functions, arrangement of multiple different prime movers of general power plants, etc., can solve problems such as large axial clearance of bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

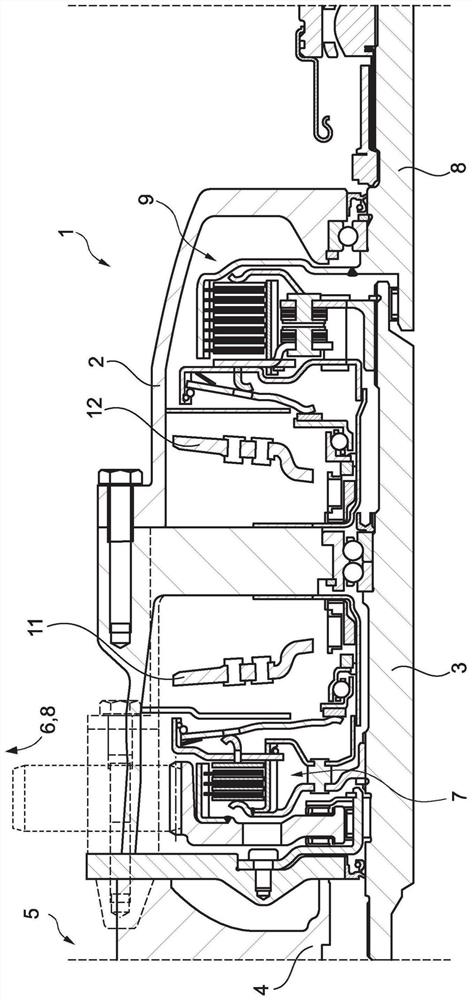

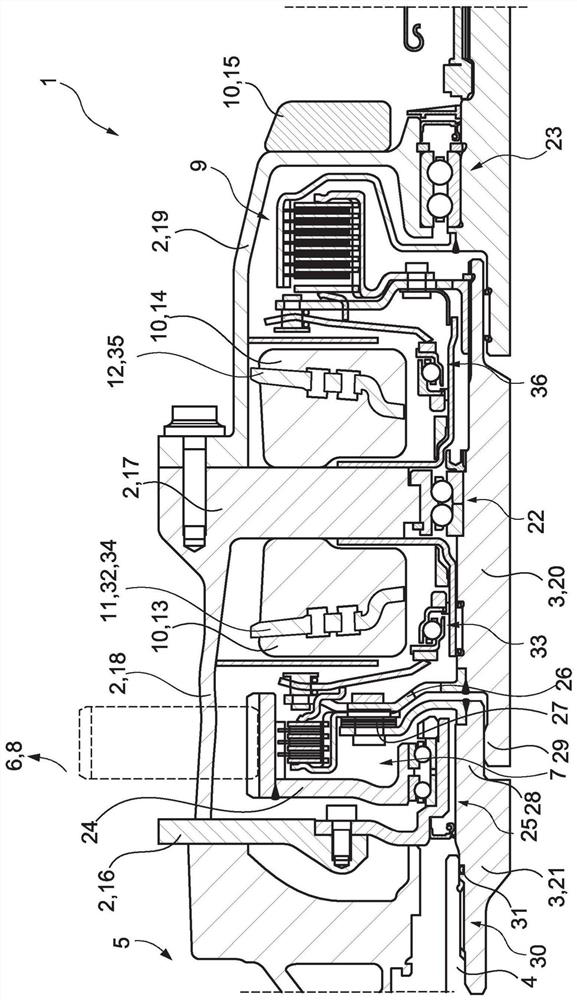

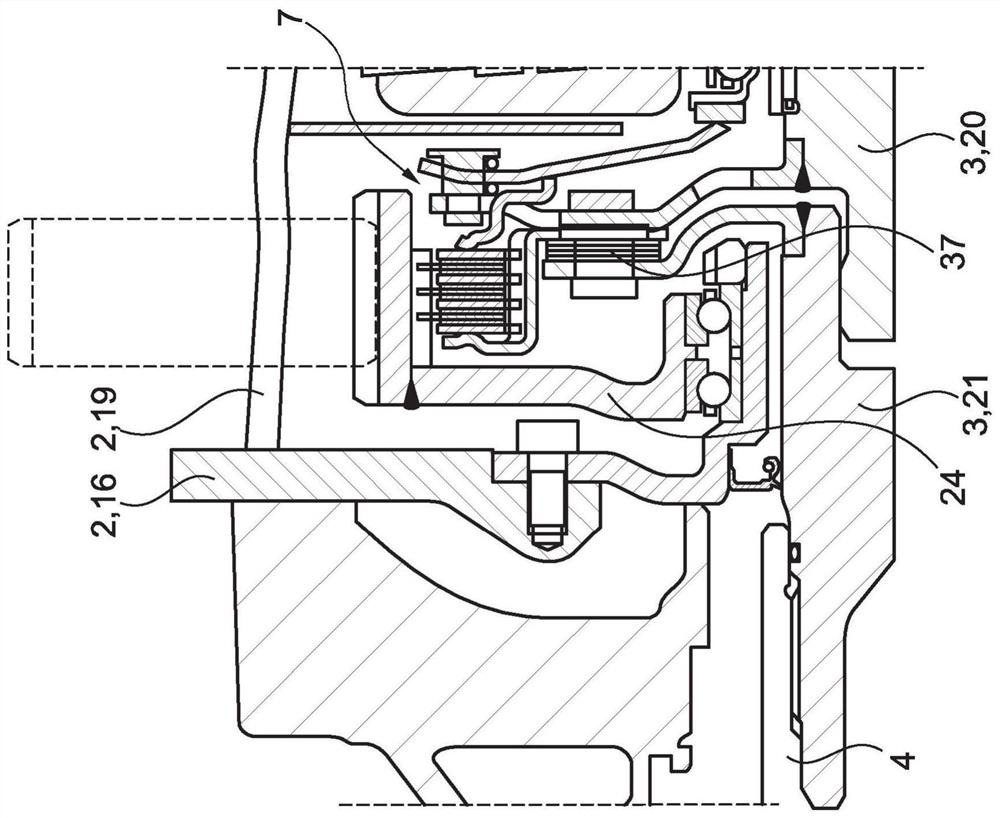

[0024] The drawings are merely schematic in nature and serve only for the understanding of the invention. The same elements have the same reference signs. The features of the exemplary embodiments are interchangeable.

[0025] figure 1 An example of a drive train unit 1 for a hybrid vehicle is shown. The drive train unit 1 has a housing 2 . The input shaft 3 is rotatably installed in the housing 2 . The input shaft 3 is arranged to be attached in a rotationally fixed manner to the output 4 of the transmission 5 . The transmission 5 is only shown in its position. The drive train unit 1 is operatively connected to a transmission 5 and forms a transmission unit with the transmission. The transmission 5 is realized as an automatic transmission. The output 4 of the transmission 5 is connected to the input shaft 3 in a rotationally fixed manner (in the form of a transmission output shaft). The output 4 is preferably connected in a rotationally fixed manner to the input shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com