Live pig cleaning equipment for livestock breeding

A technology for cleaning equipment and pigs, which is applied in animal husbandry, applications, cleaning devices, etc. It can solve the problems of adjustment, insufficient practicability, and inability to massage pigs, so as to reduce the difficulty of cleaning and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

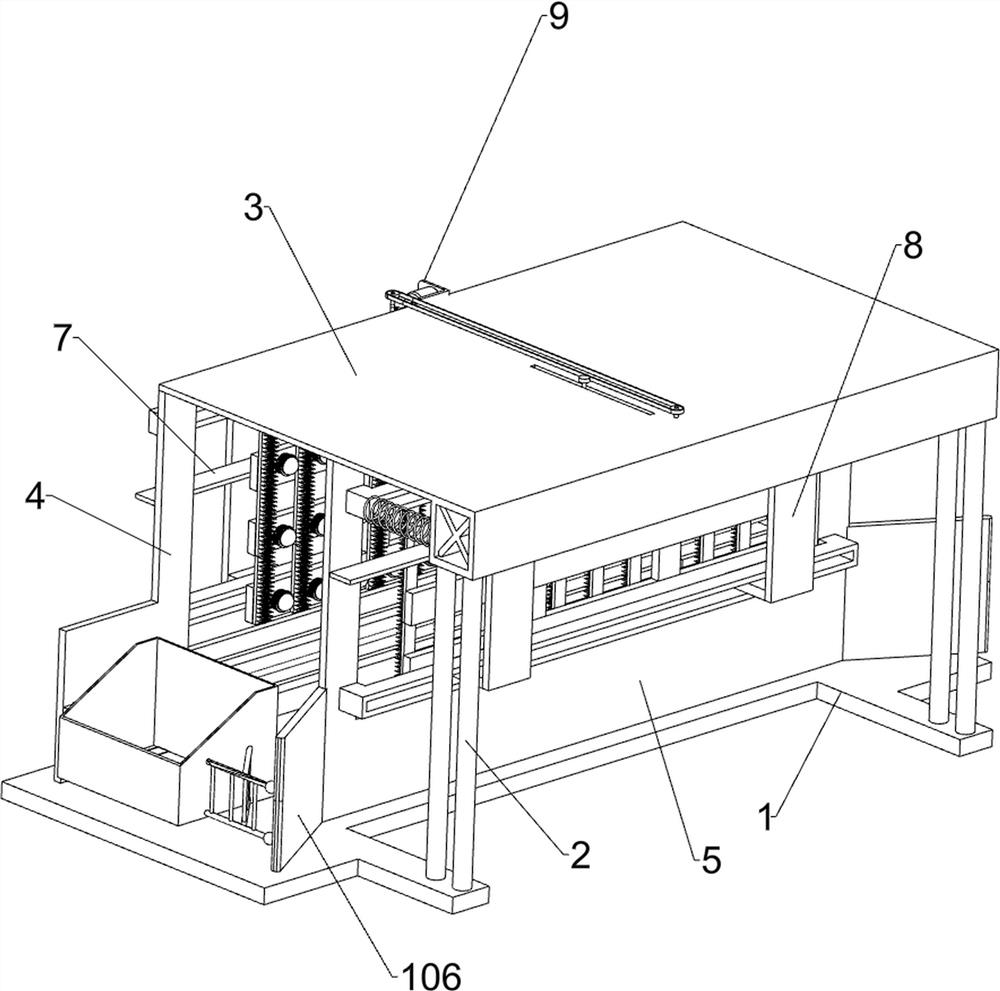

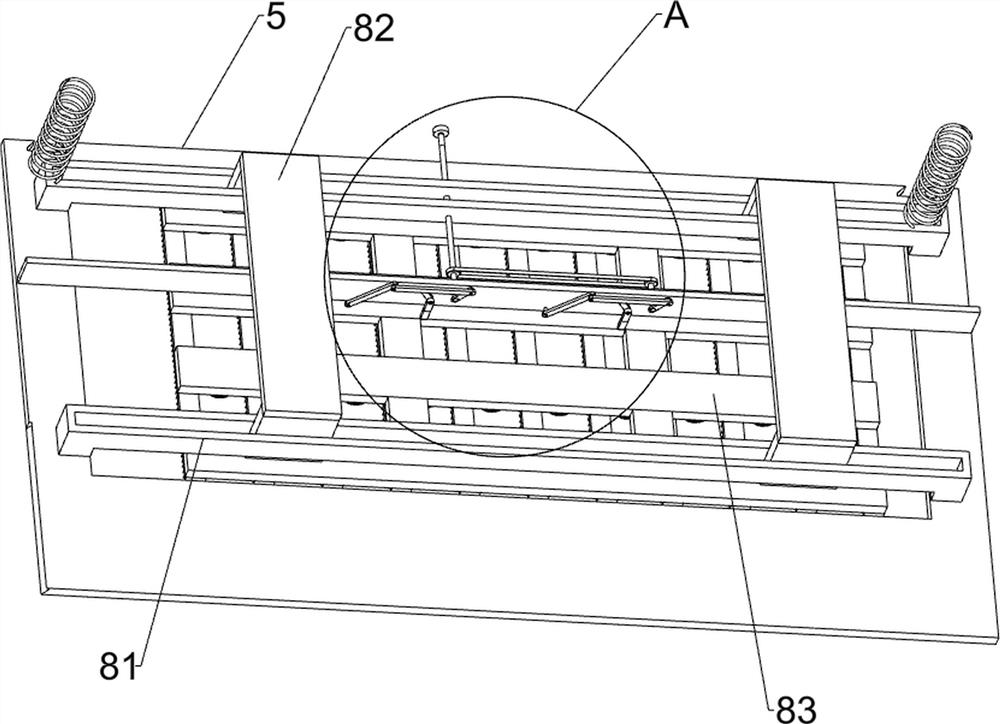

[0025] A pig cleaning equipment for animal husbandry, such as Figure 1-5 As shown, it includes a bottom plate 1, a support column 2, a top plate 3, a fixed plate 4, a movable plate 5, a first spring 6, a mounting plate 7, a cleaning mechanism 8 and a driving mechanism 9, and the front side of the top of the bottom plate 1 is connected with a support column 2 , the top rear side of the bottom plate 1 is connected with a fixed plate 4, the top plate 3 is connected between the fixed plate 4 and the top of the supporting column 2, the front side of the bottom of the top plate 3 is slidably connected with a movable plate 5, and the movable plate 5 is connected to the outer side of the fixed plate 4 The middle part is connected with a mounting plate 7, a cleaning mechanism 8 is installed on the movable plate 5 and the fixed plate 4, a driving mechanism 9 is connected between the movable plate 5 and the fixed plate 4, the driving mechanism 9 is connected with the cleaning mechanism 8...

Embodiment 2

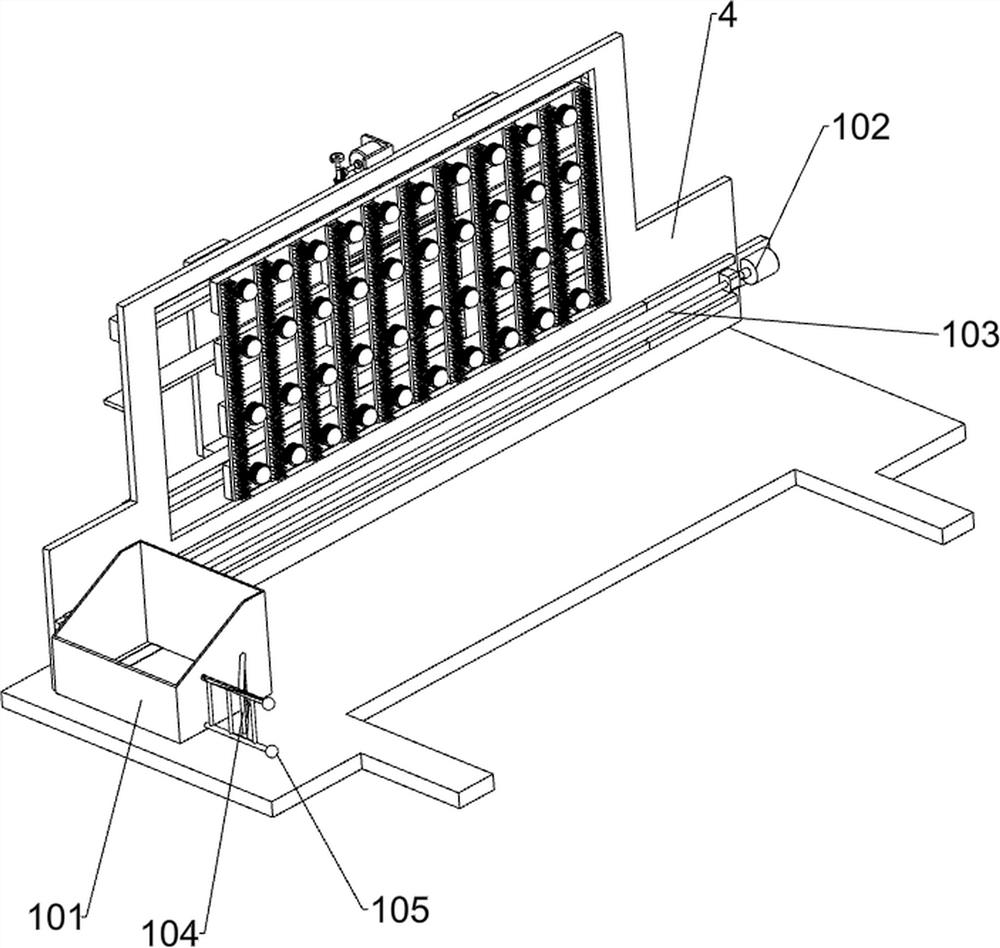

[0030] On the basis of Example 1, such as figure 1 and Figure 6 Shown, also comprise inducing mechanism 10, inducing mechanism 10 comprises feeding trough 101, deceleration motor 102, threaded rod 103, fixed frame 104, ball 105 and swash plate 106, and fixed plate 4 lower front sides are connected with sliding type. Feeding trough 101, fixed plate 4 front side right parts are equipped with decelerating motor 102, are connected with threaded rod 103 on the output shaft of decelerating motor 102, threaded rod 103 is connected with fixed plate 4 rotations, threaded rod 103 and feeding trough 101 Connected by threaded connection, the front side of feeding tank 101 is connected with fixed mount 104 by welding, the front end of fixed mount 104 is rotatably equipped with ball 105, and the bottom of movable plate 5 left and right ends is connected with oblique. The plate 106 and the rear side of the swash plate 106 are in contact with the balls 105 .

[0031]Put pig food into the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com