Vertical mixer with good mixing effect and for calamine powder processing

A vertical mixer, calamine powder technology, applied in mixers, mixers with rotary mixing devices, mixer accessories and other directions, can solve the problems of single mixing method, reduced mixing efficiency, and insufficient space for full mixing, etc. Full mixing, improving efficiency, and various mixing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

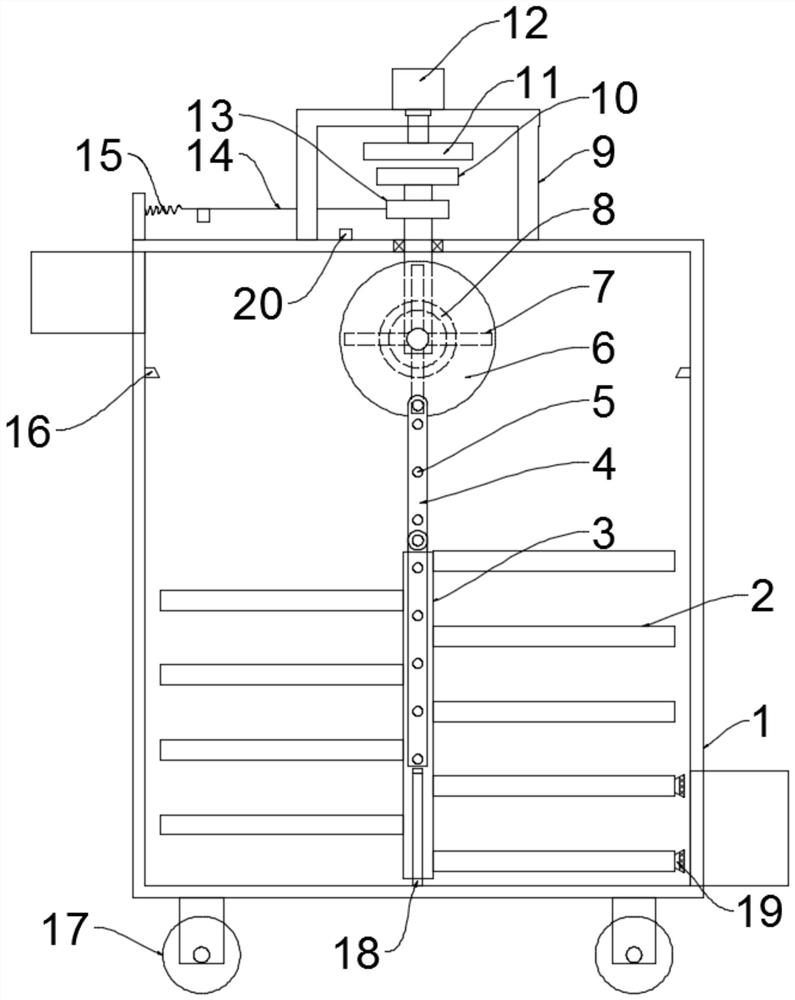

[0022] see figure 1 , in the embodiment of the present invention, a vertical mixer for calamine powder processing with good mixing effect, comprising a cylinder 1 and a mixing unit, the bottom of the cylinder 1 is evenly and symmetrically fixed with rollers 17, which facilitates the movement of the device, The top of one side of cylinder body 1 is provided with a material inlet, and the bottom of one side of cylinder body 1 is provided with a material outlet. Valves are installed on both the material inlet and the material outlet. The mixing unit includes a rotating shaft and a drive for driving the rotating shaft to rotate. Mechanism, bevel gear 8, turntable 6, first connecting rod 4, installation rod 3 and stirring rod 2, the rotating shaft vertically runs through the middle of the top of the cylinder 1 and is connected to the top of the cylinder 1 in rotation, and the rotating shaft is located in the cylinder 1 An installation shaft is vertically pierced and rotated on the ...

Embodiment 2

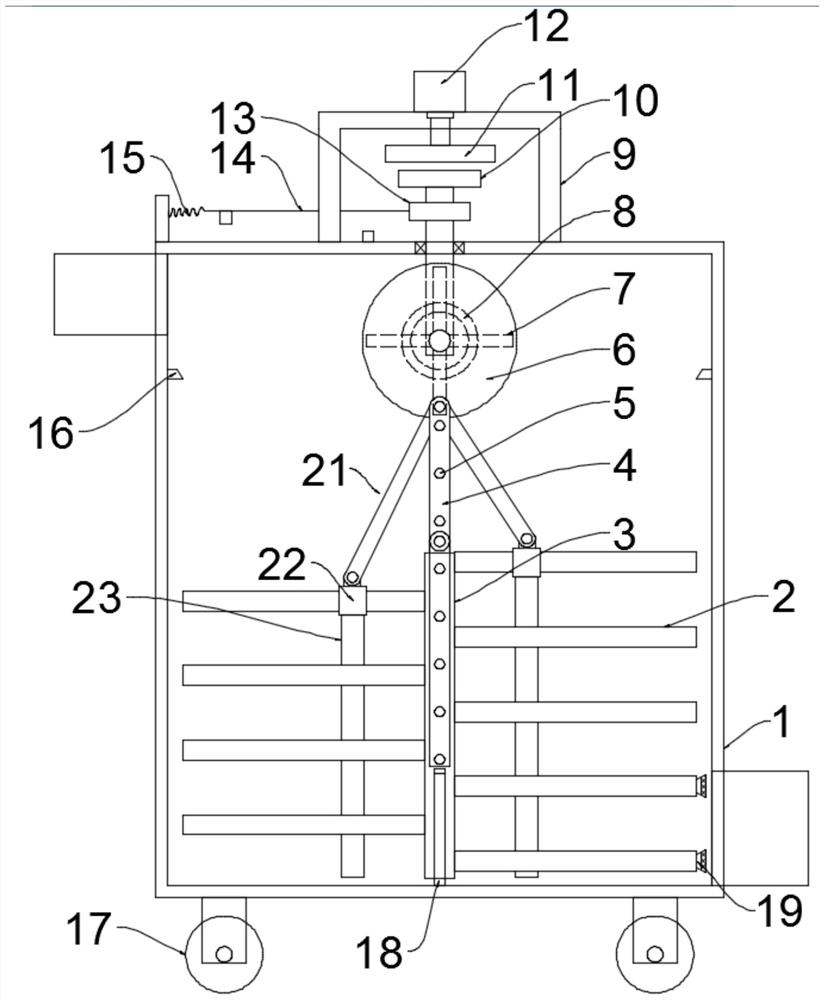

[0026] see figure 2 The difference between this embodiment of the present invention and Embodiment 1 is that two second connecting rods 21 are hinged at the hinged position between the end surface of the turntable 6 and the first connecting rod 4, and the other end of the second connecting rod 21 is hinged with a slider Sleeve 22, sliding sleeve 22 slides and fits on the adjacent stirring rod 2, and the vertical movable rod 23 is fixed on the described sliding sleeve 22, when the turntable 6 rotates, the sliding sleeve 22 and the movable rod 23 are driven by the second connecting rod 21 along the With the reciprocating movement of the stirring rod 2, the stirring and mixing range is further expanded, and the mixing efficiency is improved.

[0027] The working principle of the present invention is: when working, the driving mechanism drives the rotating shaft to rotate, the rotating shaft drives the installation shaft to revolve, the installation shaft drives the turntable 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com