A high wear resistance piston ring end surface fine grinding processing device

A piston ring end, high wear resistance technology, used in grinding drive devices, grinding/polishing safety devices, metal processing equipment, etc., can solve problems such as health hazards, large amounts of dust, environmental pollution, etc. , the effect of avoiding hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

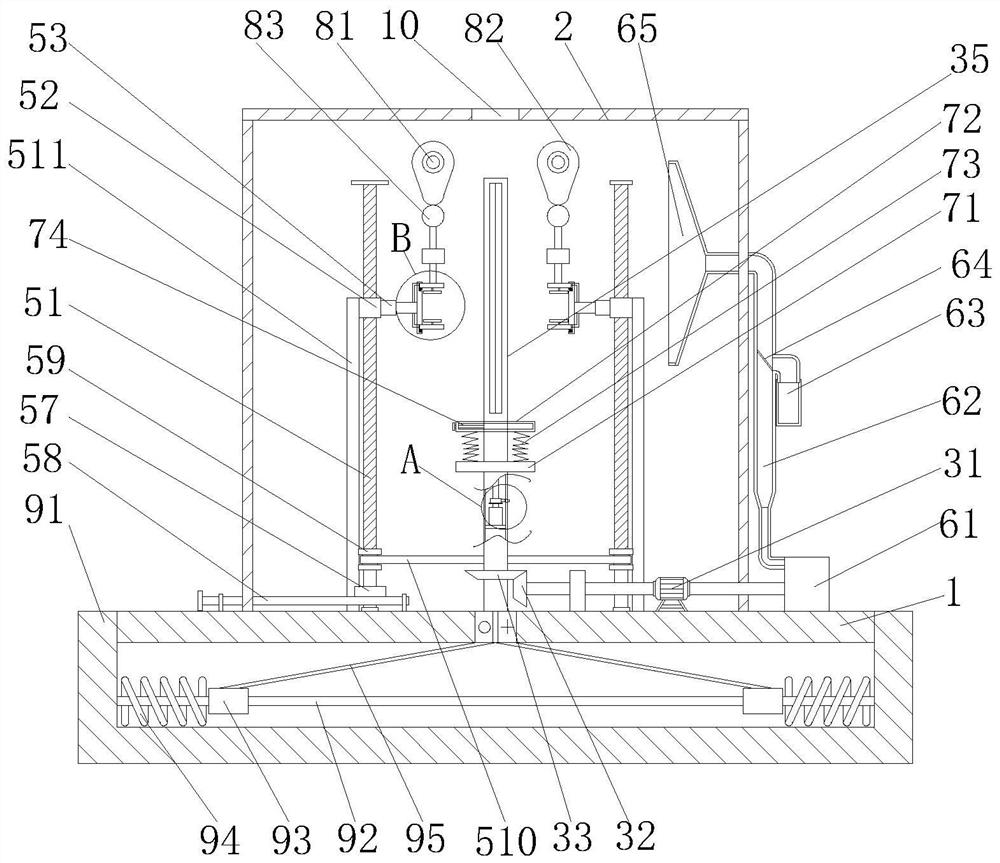

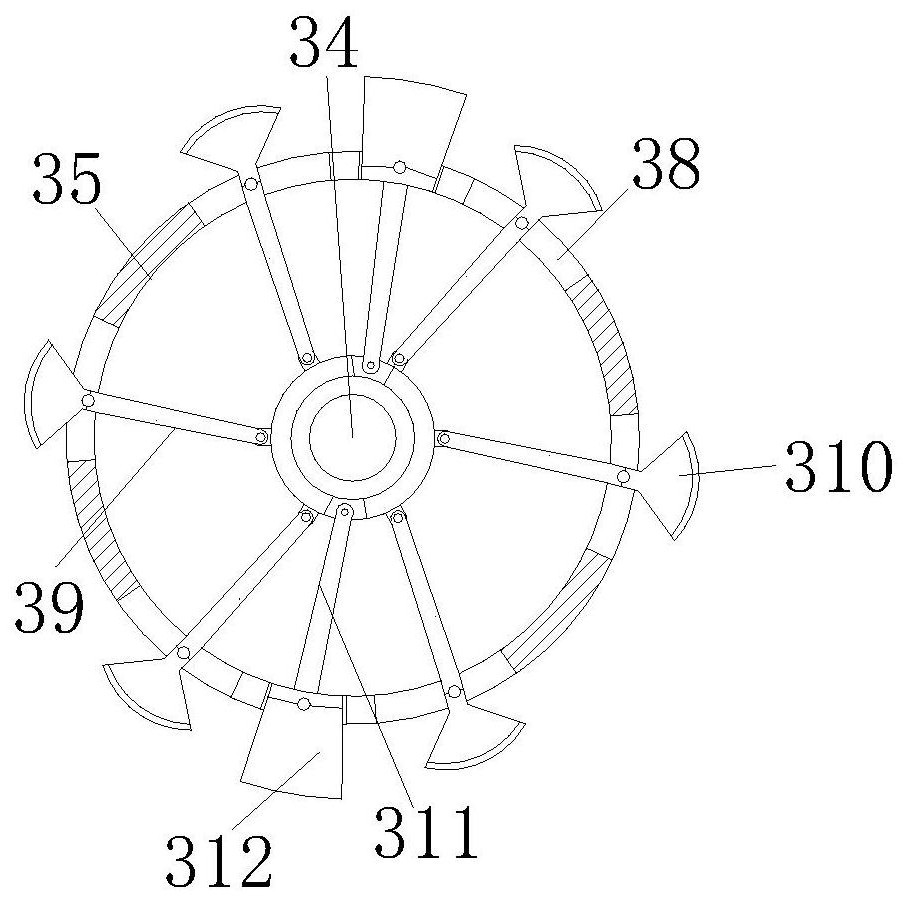

[0029] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 7 , to further elaborate the present invention.

[0030] A high wear resistance piston ring end surface fine grinding processing device, including a base 1, a working chamber 2, a material placement mechanism 3, a grinding mechanism 5, a dust suction mechanism 6 and a buffer mechanism 9, the upper surface of the base 1 is fixed and installed There is an operation compartment 2, and the lower surface of the inner cavity of the operation compartment 2 is symmetrically provided with a grinding mechanism 5, and the grinding mechanism 5 is distributed on both sides of the material placement mechanism 3, and the right side of the grinding mechanism 5 is provided with a dust suction mechanism 6, and the lower surface of the base 1 is provided There are buffer mechanisms 9 of which:

[0031] The material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com