Three-wire rail-holding high-speed maglev train system

A magnetic levitation train and magnetic levitation technology, applied in sliding/floating railway systems, motor vehicles, electric vehicles, etc., can solve the problems of the complexity of the magnetic levitation control system, the increase of the cost of the vehicle control system, and the inability to further increase the speed of high-speed trains, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

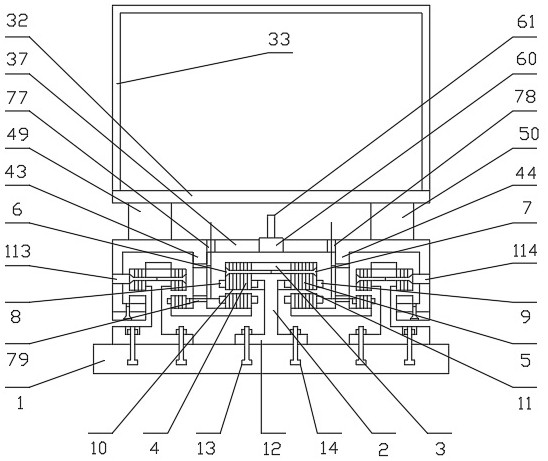

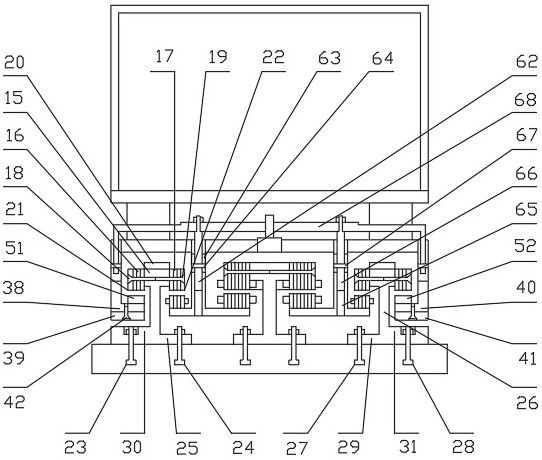

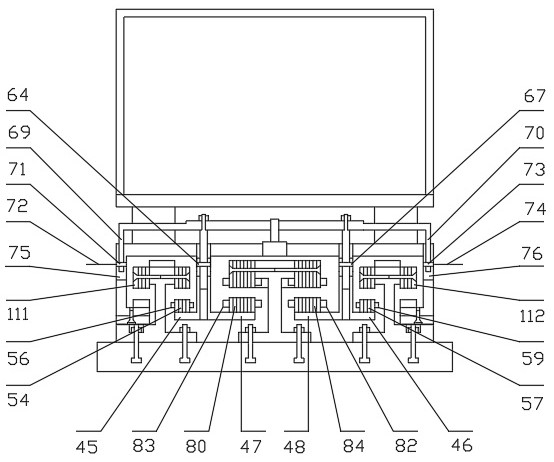

[0011] The following description will be made with reference to the drawings and examples.

[0012] at Figure 1- Figure 5The three-line rail-hugging high-speed maglev train system is provided with a long track subgrade, which, like the long high-speed railway subgrade, is a long platform built along the track route and paved with stones. The long track subgrade is provided with a chevron-shaped track, the cross section of which is chevron-shaped, and the chevron-shaped long track is provided with a plurality of reinforced concrete beams 1, which are evenly spaced and parallel to each other and arranged on the long track subgrade in order. The upper middle part of a plurality of reinforced concrete beams is provided with a stator track line 2, the upper end of the stator track line is provided with a square long iron 3, the left end of the square long iron is provided with a left stator core 4, the right end is provided with a right stator core 5, the left stator core is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com