Thin film bag forming edge-sealing device and method

An edge sealing device and film technology, which is applied in the directions of packaging material feeding device, packaging, transportation packaging, etc., can solve the problems of poor film absorption, film bag wrinkles, and reduce the quality of film bag opening and edge sealing, so as to improve adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

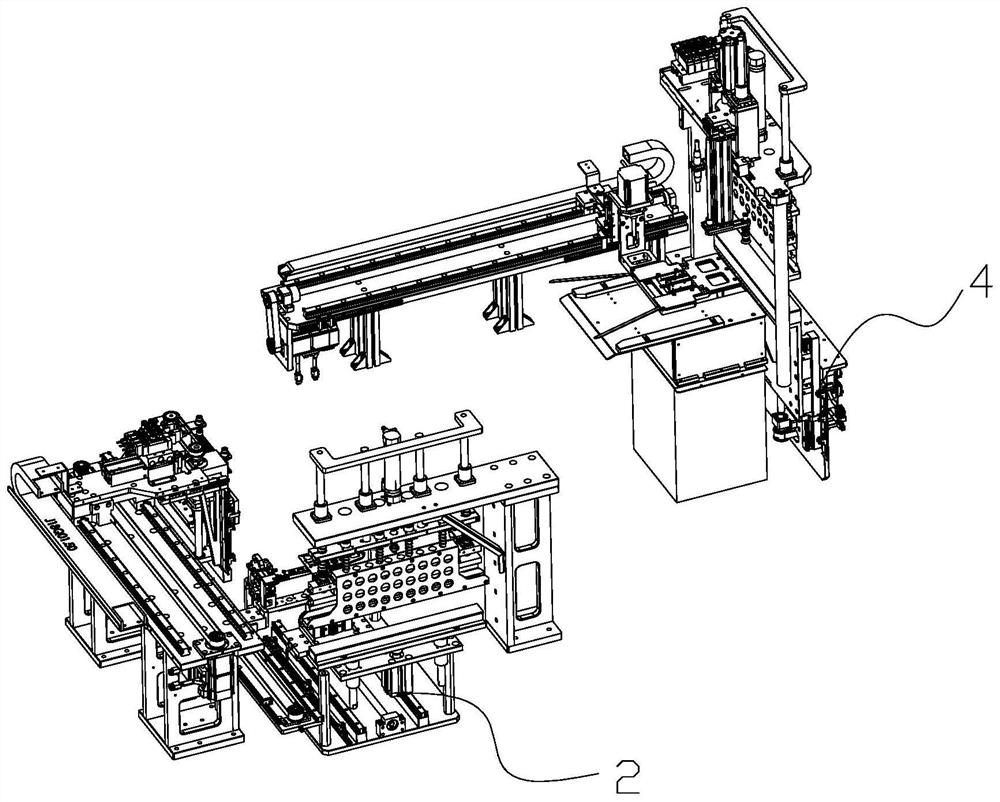

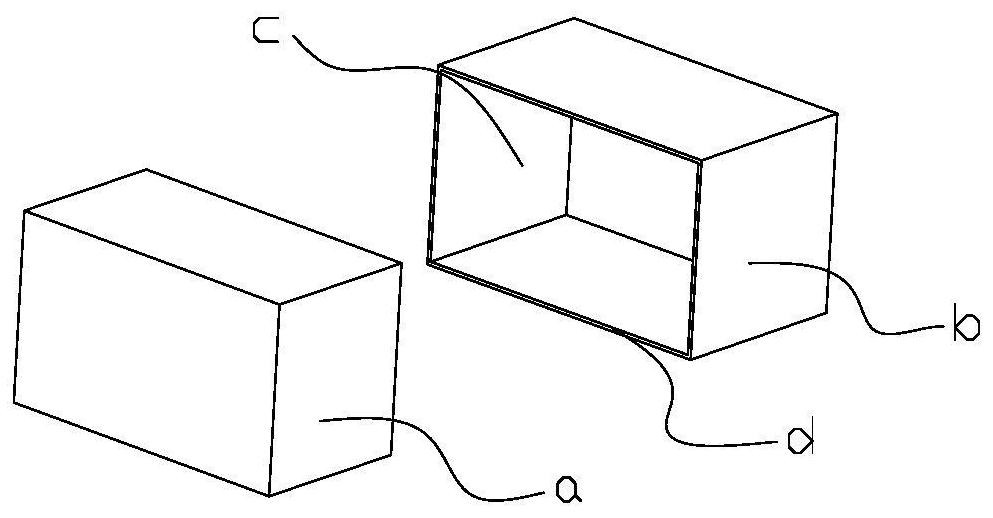

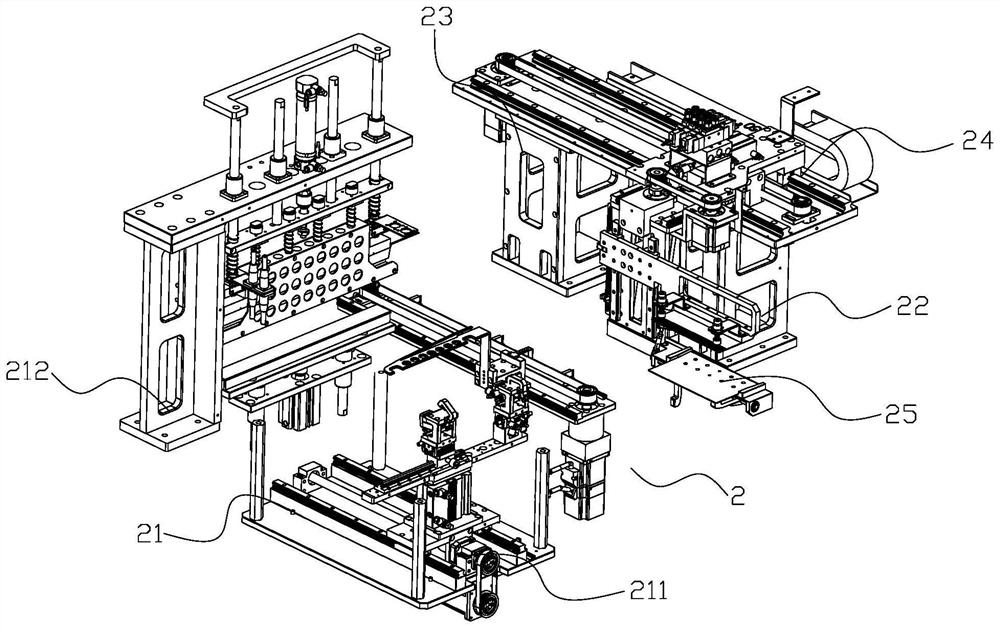

[0032] Such as figure 1 Shown is a kind of film packaging equipment, which includes a workbench and a film feeding device fixed on the workbench, a film bag forming bag supporting device 2, a packing box feeding device, an edge sealing device and a corner cutting device; The outlet of the feeding device is connected with the inlet of the film bag forming and supporting device, and the outlet of the film bag forming and supporting device 2 is respectively connected with the outlet of the packing box feeding device and the inlet of the edge sealing device 4; The feed port and discharge port of the corner device are respectively connected with the discharge port of the edge banding device 4 and the unloading station; the film feeding device is used for feeding the film; the film bag forming and supporting device 2 is used for forming the film and The prepared film bag is stretched; the packaging box feeding device is used for feeding the packaging box; the edge sealing device 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com