Adhesive tape adhesion facility based on vacuum insulated panel

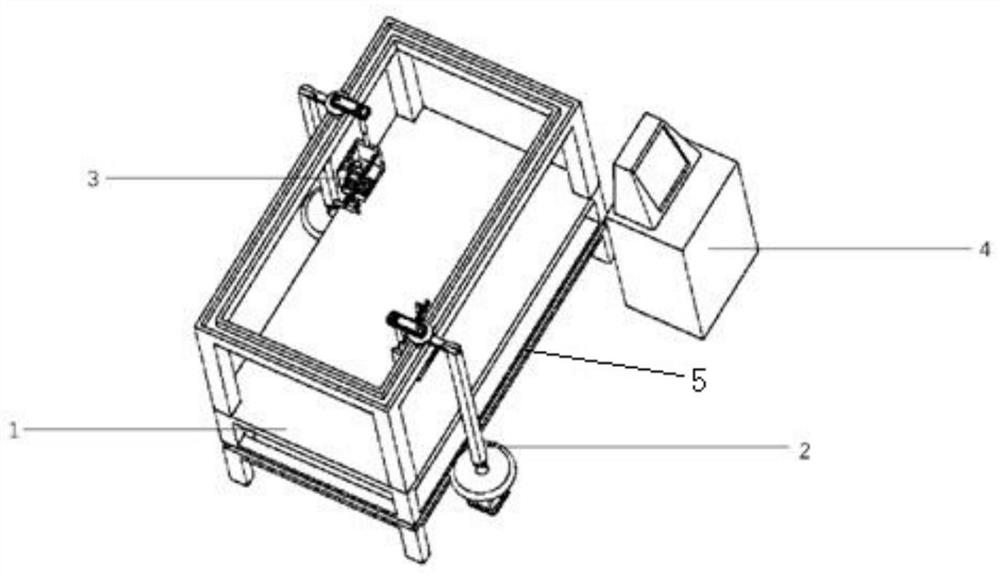

A technology of vacuum insulation panels and glue sticking, which is applied in the direction of sending objects, thin material handling, transportation and packaging, etc. It can solve the problems of insulation panel damage, easy damage in quantity, and different sizes, so as to reduce damage, reduce costs, and increase speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

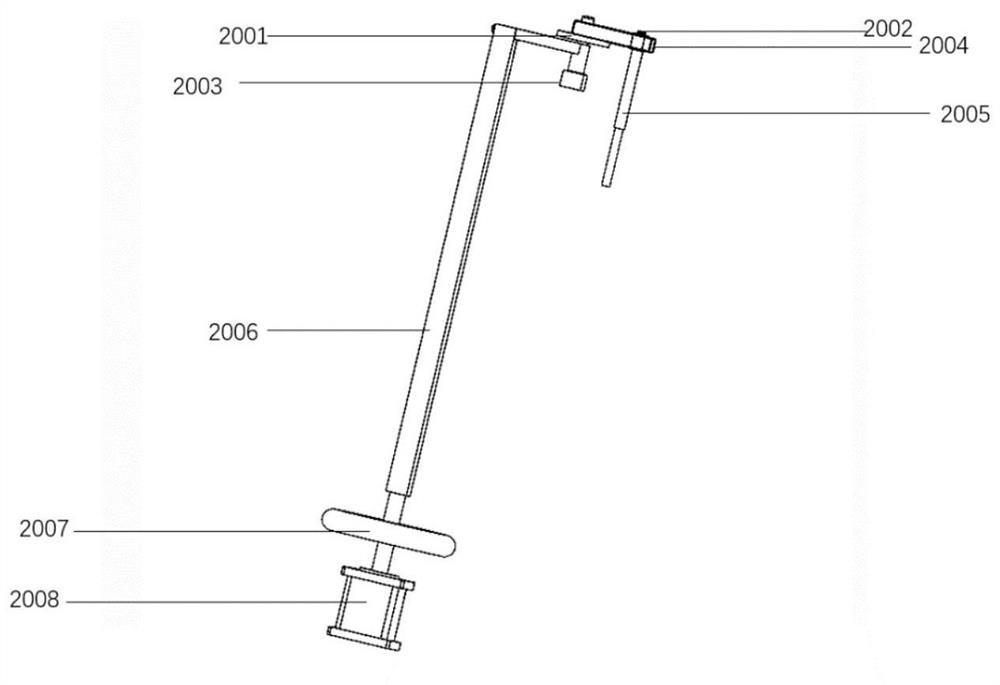

[0051] The user first places the vacuum insulation panel on the platform, adjusts the position of the gluing device 3 through the scale on the cross bar 2004, and places the required tape in the ring groove 3001 of the gluing device 3, straightens the tape, Make the non-adhesive surface tightly attached to the roller 3002 and the pressure cylinder 3005, and then the cylinder 3011 descends, driving the pressure cylinder 3005 to press the adhesive tape tightly on the slant plate 3012, and the inclined surface of the slant plate 3012 is coated with a non-stick layer to prevent Adhesive tape is attached to the swash plate 3012.

[0052] At this time, the partition plate 3014 is in the blocking channel, so that the upper and lower splints of the blocking portion 3013 open at an angle, forming a V shape, and the tape in the middle gap passes through the splint.

[0053] Start the device, the motor 2008 drives the roller 2007 to move on the platform 1, and moves between the long alum...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap