Zinc coating electroplating system and electroplating method

A zinc coating and frame technology is applied in the field of zinc coating electroplating system and electroplating, which can solve the problems of incapable of high-efficiency electrogalvanizing of tubular parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

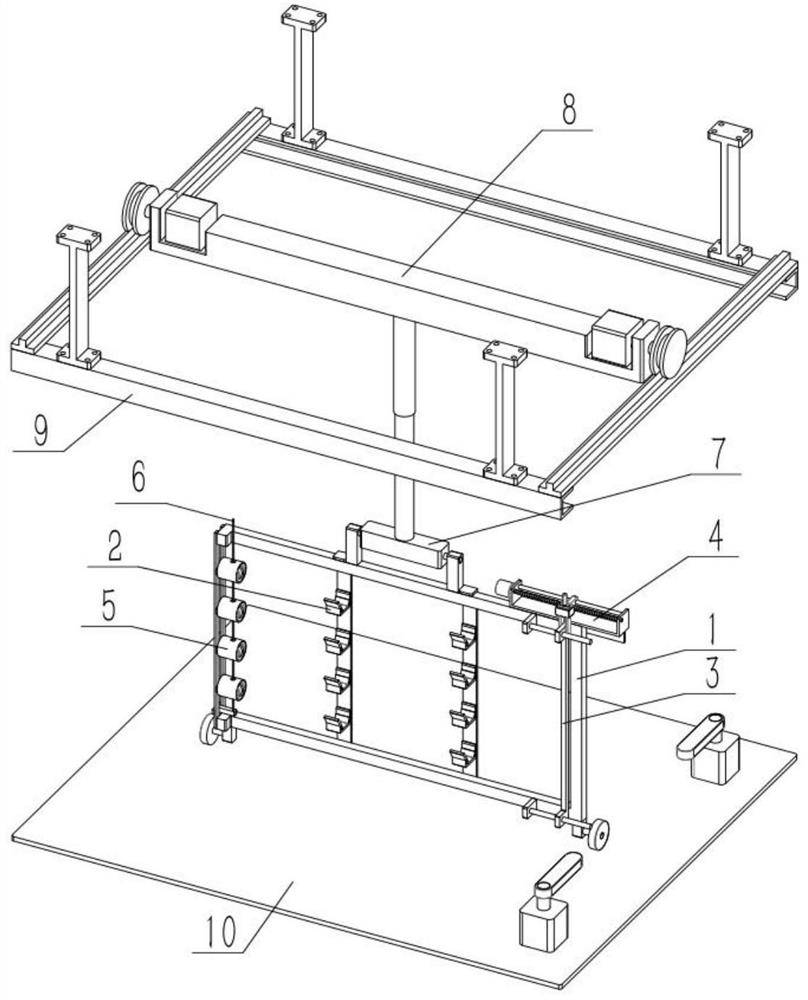

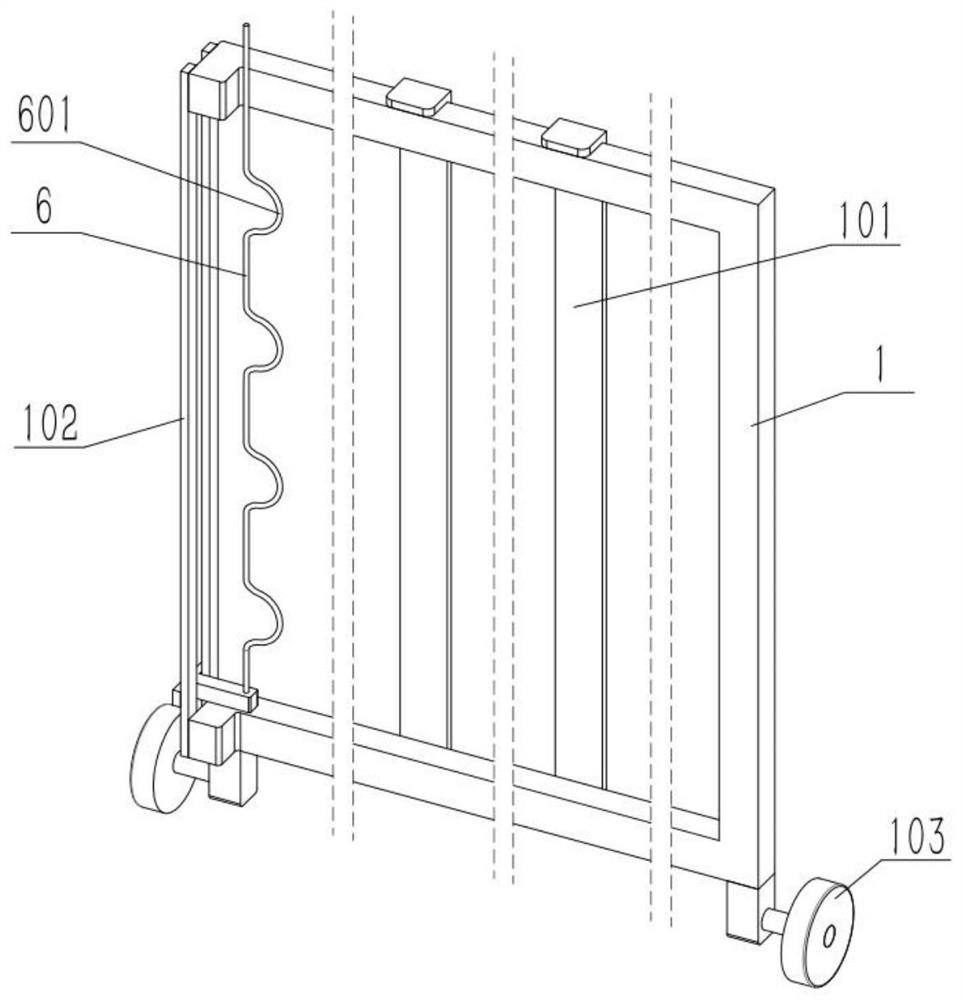

[0035] like Figure 1-10 As shown, a zinc coating electroplating system includes a frame 1, a hanging plate 101, a side plate 102, a support portion 2 and a wire 6, and a hanging plate 101 is fixedly connected to the left and right sides of the middle part of the frame 1, and the side plate 102 is affixed to the left end of the frame 1, the lower end of the wire 6 is affixed to the lower end of the side plate 102, and a plurality of brackets 2 are evenly fixed longitudinally on each hanging board 101, and the brackets 2 on the two hanging boards 101 Symmetrical setting. Place the longer tubular part, hereinafter referred to as the part, on the two holders 2 at the same height, and connect the upper end of the wire 6 to the negative pole, preferably the upper side of the wire 6 is also fixed on the frame 1 , so that the overall position of the wire 6 between two fixed points of itself remains unchanged. Then the left end of the part is contacted with the right end of the wire...

specific Embodiment approach 2

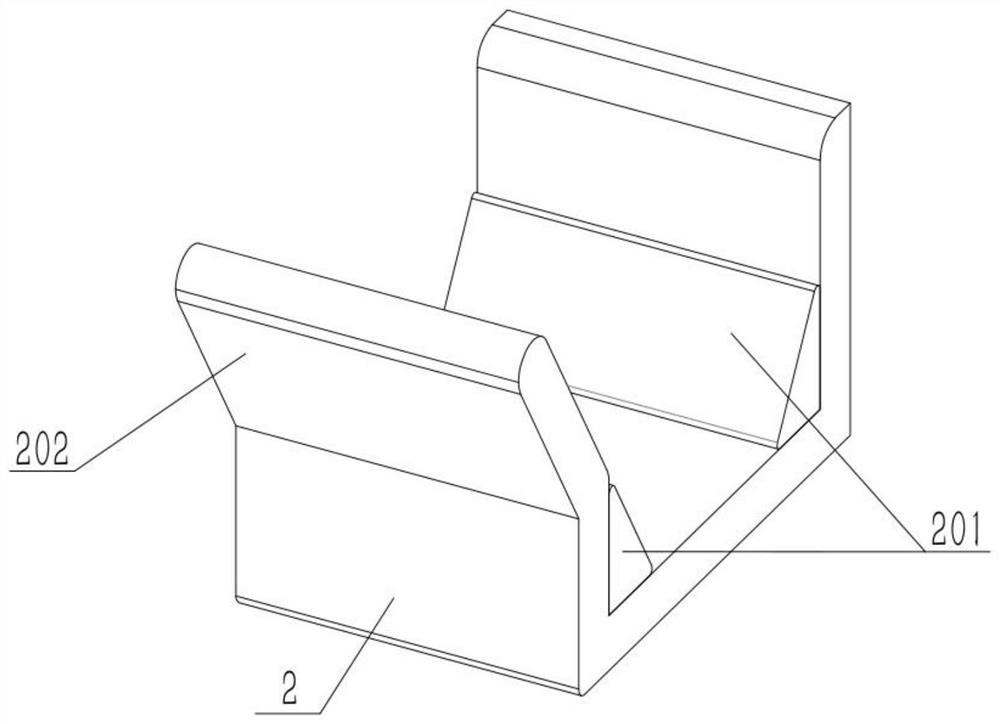

[0037] like Figure 1-10 As shown, the zinc coating electroplating system also includes a protection pad 201, and a protection pad 201 is fixedly connected to the front and rear ends of the inner end of each support portion 2. After the parts are placed in the holder 2, the parts are in contact with the two protection pads 201. The protection pads 201 can prevent the parts from being knocked and damaged, and avoid fatigue caused by manual placement due to gentle handling. The two protective pads 201 in each support portion 2 have two line contacts with the underside of the part, so that the placement is more stable. Place the part directly in the support part 2. When the bottom end of the part is in line contact with the support part 2, the pressure on the lower end of the part is too large, which is not conducive to protecting the part. Therefore, two protective pads 201 in one support part 2 are used for support. And the protection effect is better.

specific Embodiment approach 3

[0039] like Figure 1-10 As shown, the zinc coating electroplating system also includes an inclined part 202, and the rear end of the upper end of each support part 2 is integrally connected with an inclined part 202, and the front end face of each inclined part 202 coincides with the front end face of its nearest protective pad 201 . The inclined portion 202 increases the width of the upper opening of the support portion 2 and reduces the accuracy of placing parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com