Two-sided AB-color light, thin, fluffy and warm-keeping fabric and production process thereof

A production process and fabric technology, applied in the field of spinning and weaving, can solve the problems of heavy fabric, uncomfortable wearing, easy deformation and airtightness, etc., and achieve the effect of good resilience and shape retention performance, and light texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

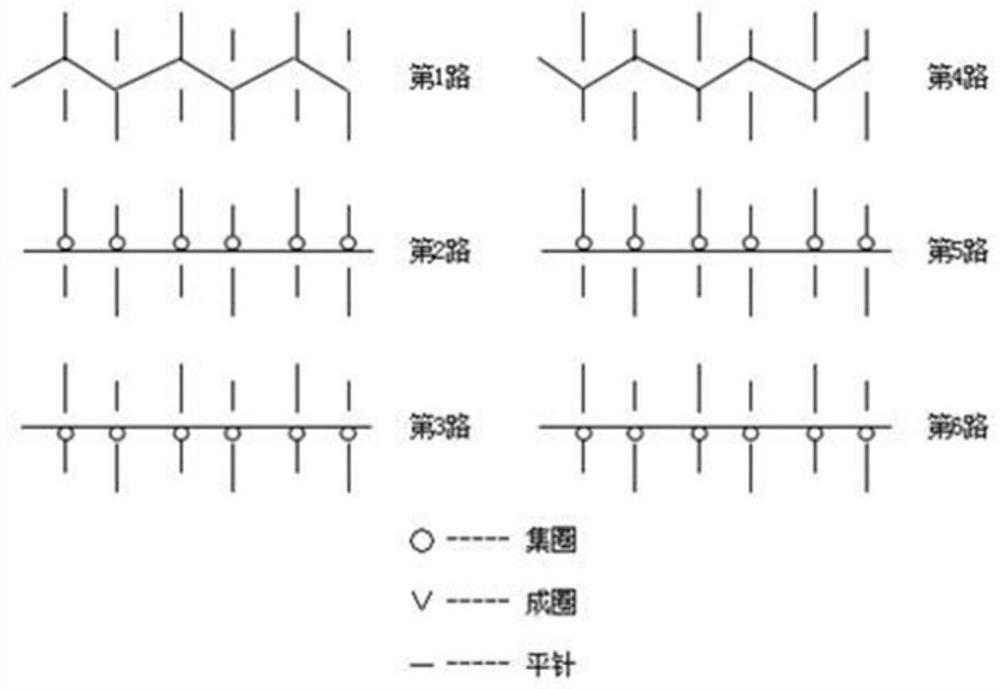

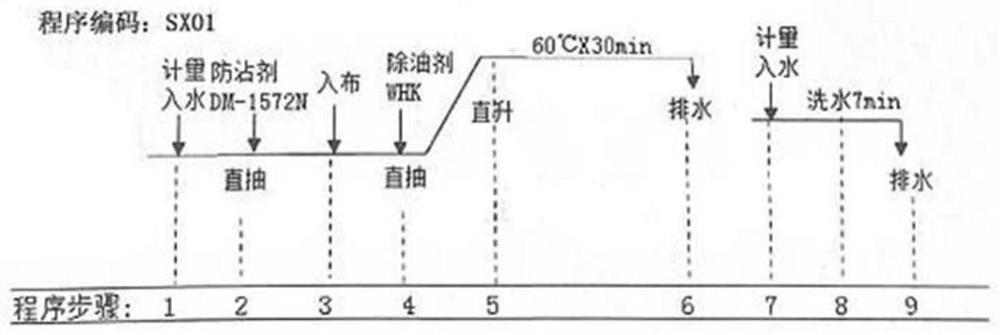

Method used

Image

Examples

no. 1 example

[0035] In the present embodiment, a kind of production technology of two-sided AB color frivolous fluffy warm-keeping fabric comprises the following steps:

[0036] Step 1: Spinning:

[0037]Spinning face yarn: fully mix the colored polyacrylonitrile fiber containing 10% stock solution and 20% polyacrylonitrile expanded fiber without coloring, and then fully mix with 70% viscose colored fiber for pre-spinning, and carry out 4 times Drawing, and finally spun into 40S / 1 British count by compact siro spinning, knitting yarn with a twist coefficient of 350, the fiber length is 38mm, and 40s / 165R / 20A bulked / 10A / 5 wool Huafu color spinning as a veil;

[0038] Spinning bottom yarn: fully mix the colored polyacrylonitrile fiber containing 10% stock solution and 20% polyacrylonitrile expanded fiber without coloring, and then carry out pre-processing with 65% viscose colored fiber and 5% wool natural fiber Spinning is fully mixed, drawn for 4 times, and finally spun into 40S / 1 British...

no. 2 example

[0050] In the present embodiment, a kind of production technology of two-sided AB color frivolous fluffy warm-keeping fabric comprises the following steps:

[0051] Step 1: Spinning:

[0052] Spinning face yarn: fully mix the colored polyacrylonitrile fiber containing 10% stock solution and 20% polyacrylonitrile expanded fiber without coloring, and then fully mix with 70% viscose colored fiber for pre-spinning, and carry out 4 times Drawing, and finally spun into 40S / 1 British count by compact siro spinning, knitting yarn with a twist coefficient of 350, the fiber length is 38mm, and 40s / 165R / 20A bulked / 10A / 5 wool Huafu color spinning as a veil;

[0053] Spinning bottom yarn: fully mix the colored polyacrylonitrile fiber containing 10% stock solution and 20% polyacrylonitrile expanded fiber without coloring, and then carry out pre-processing with 65% viscose colored fiber and 5% wool natural fiber Spinning is fully mixed, drawn for 4 times, and finally spun into 40S / 1 Britis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com