Stranded wire and method of manufacture therefor

A technology of twisted wire and manufacturing method, applied in the direction of cable/conductor manufacturing, cable with double twist/quad twist, circuit, etc., can solve the problem of insulator being easily crushed and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

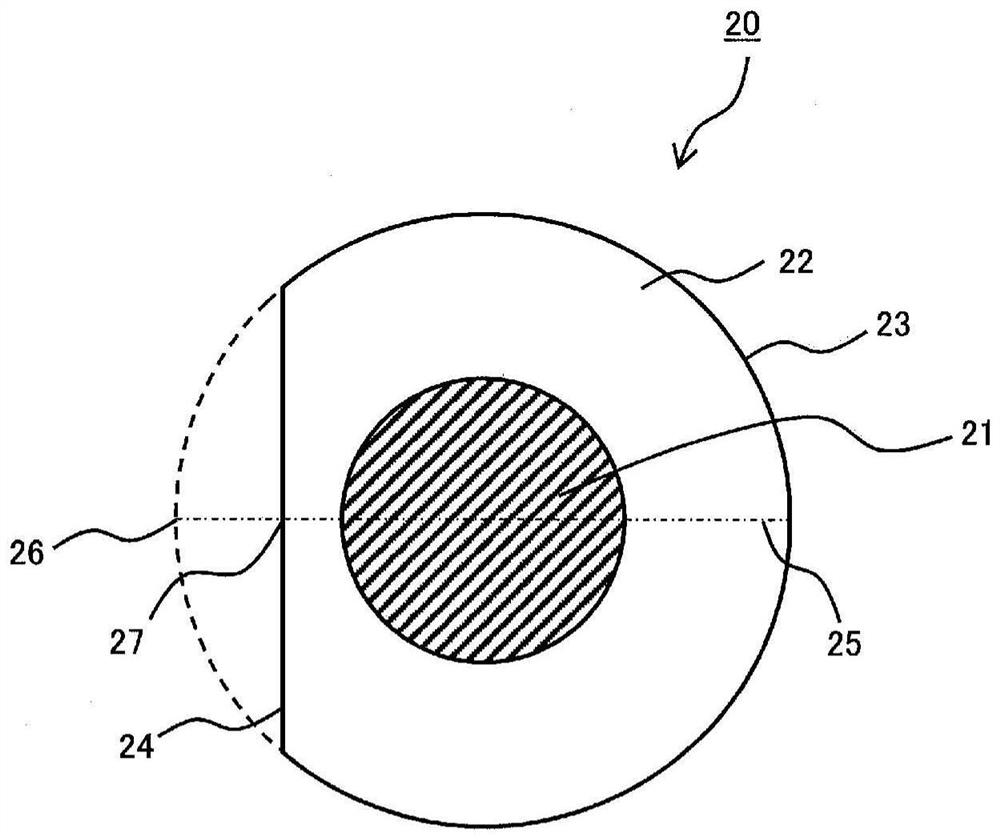

[0150] Set the covered wire (outer diameter 1.0mm, copper wire diameter 0.510mm, insulator thickness 0.245mm) in a constant temperature bath (manufactured by espec company, model: sh-241) set at 0 ℃, and let it stand until the wire temperature reaches the atmosphere temperature of the constant temperature bath (at least 10 minutes). The covered wire has copper wire and TFE / HFP / ppve copolymer a formed around the copper wire by melt extrusion molding (TFE / HFP / ppve (mass ratio): 87.5 / 11.5 / 1.0, melting point: 257 ℃ MFR: 36.3g / 10min, elastic modulus: 460Mpa, relative dielectric constant at 6GHz( ε r) Dielectric loss tangent at: 2.05, 6GHz: 3.3 × ten -4 )An insulator.

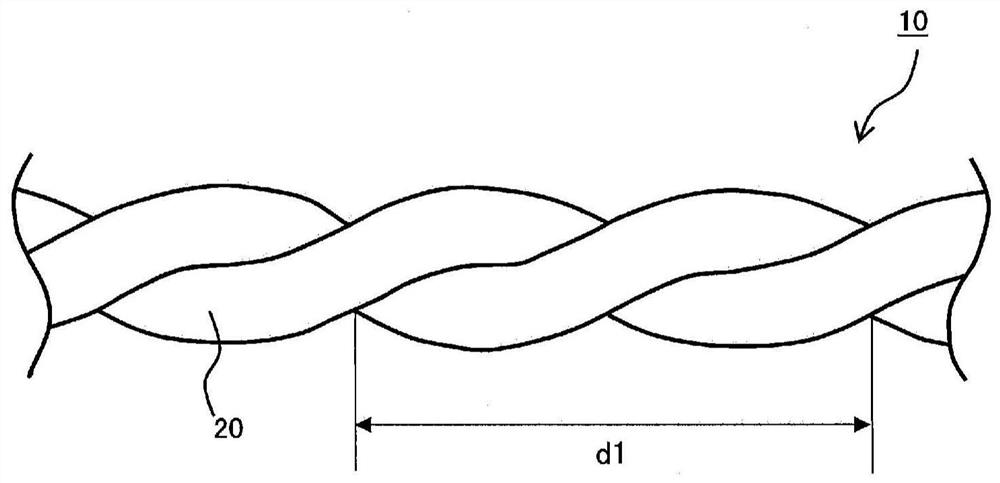

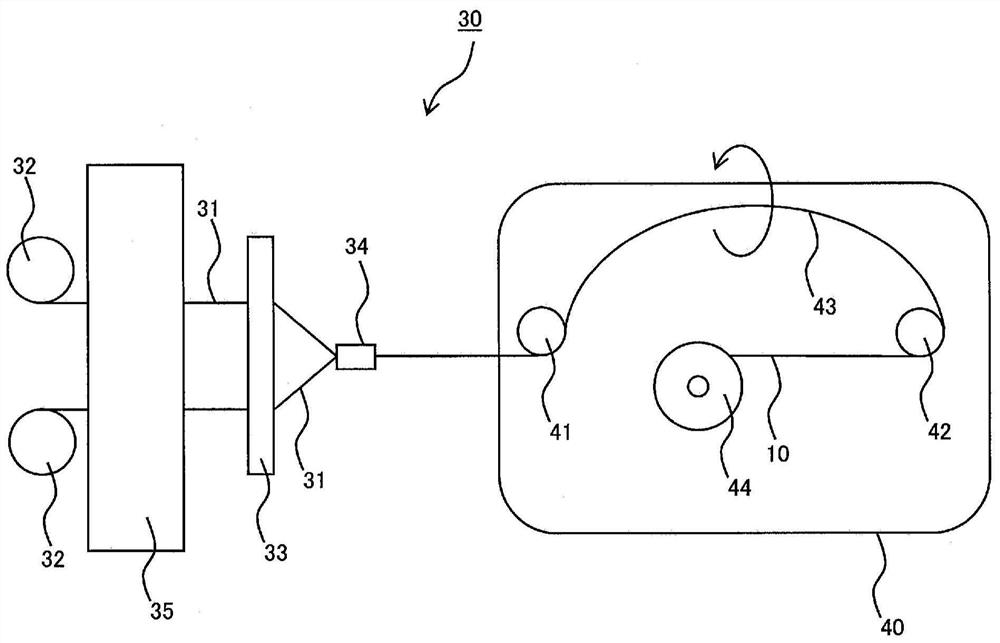

[0151] Using a twisting machine (manufactured by Tokyo ideal company, model: tw-2n), twist the cooled two coated wires to the pitch length recorded in Table 1 at about 500tpm. Here, the pitch length represents the length until a line is rotated once in the fully twisted part.

[0152] For the obtained twisted...

Embodiment 2

[0170]The set temperature of the thermostatic bath was changed to - 40 ℃. In addition, the twisted pair was made in the same way as in embodiment 1. The obtained twisted pair is evaluated in the same manner as in embodiment 1. The results are shown in Table 1.

Embodiment 3

[0172] A coated wire (1.0mm outer diameter, 0.510mm diameter of copper wire and 0.245mm thickness of insulator) is used, which has copper wire and TFE / HFP / ppve copolymer B formed around the copper wire by melt extrusion (TFE / HFP / ppve (mass ratio): 87.6 / 11.5 / 0.9, melting point: 257 ℃, MFR: 35.7g / 10min, elastic modulus: 480mpa, relative dielectric constant at 6GHz( ε r) Dielectric loss tangent at: 2.05, 6GHz: 3.3 × ten -4 )In addition, the twisted pair is made in the same way as in embodiment 1. The obtained twisted pair is evaluated in the same manner as in embodiment 1. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap