A kind of porous copper powder carrier-loaded silver-based antibacterial material and preparation method thereof

A carrier-loaded, antibacterial material technology, applied in the field of antibacterial materials, can solve the problems of easy collapse and shrinkage of the structure, unsuitable for industrialization, and limited antibacterial effect, etc., to achieve pore structure that is not easy to collapse, strong controllability of size, and source of raw materials broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

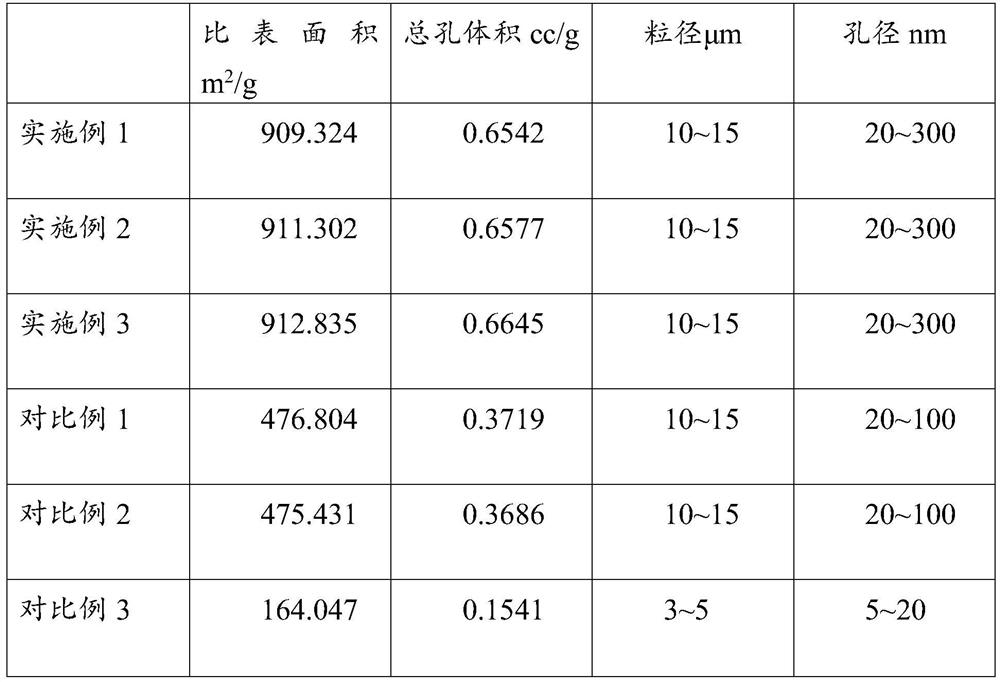

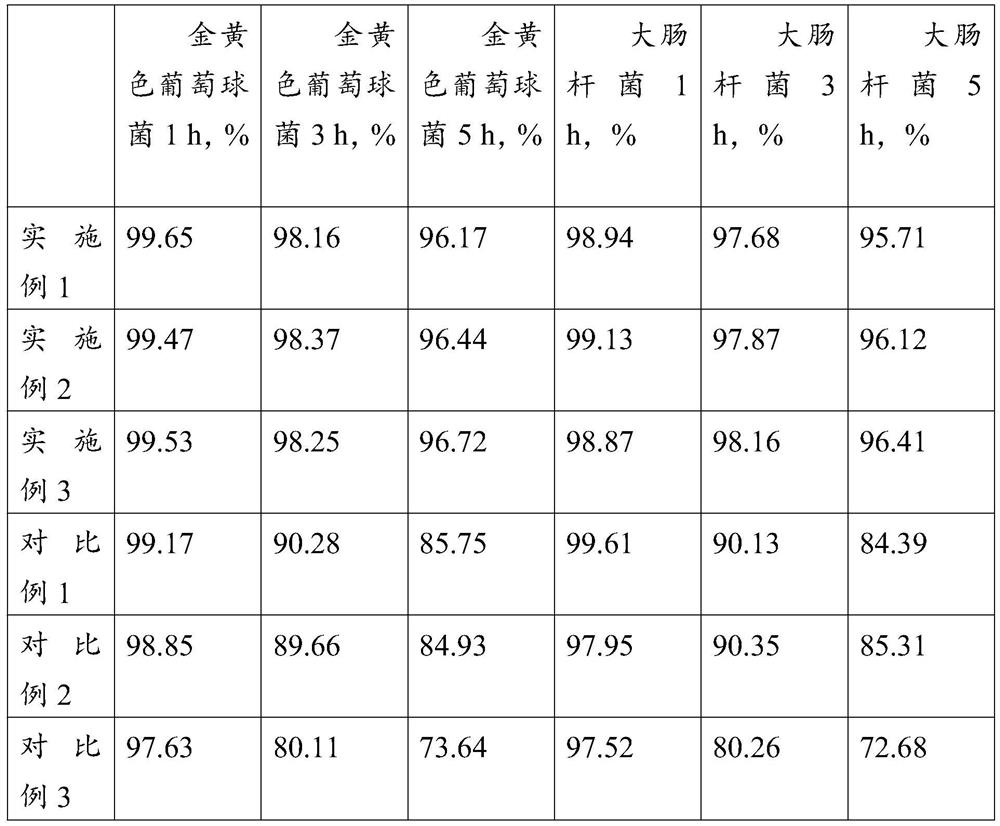

Examples

Embodiment 1

[0066] 1) Filter 500ml of sugarcane juice with a 180-mesh filter cloth, control the pH to 3 with dilute hydrochloric acid; hydrolyze at 40°C for 3 hours, at a voltage of 10V, and a current density of 0.04A / cm 2 Remove impurities in the electrolytic cell for 8 hours, dilute and control the vitamin C content to 0.01 μg / 100g (measured by a fluorescence spectrophotometer), then filter through a microfiltration ceramic membrane with a membrane pore size of 50nm for 20 hours, dissolve in 1000ml methanol and stir evenly to obtain a mixed solution A ;

[0067] 2) Add 400 g of 0.1 mol / L copper salt solution, add 8 g of PVP, stir evenly, heat to 50 ° C, and adjust the pH to 9 with ammonia water to obtain the mixed solution B;

[0068] 3) Add diethylene glycol monomethyl ether to mixed solution A and mixed solution B under a 650W ultrasonic field, according to the volume ratio of mixed solution A, mixed solution B and diethylene glycol monomethyl ether 3.2:5.8:0.8 Mix and stir for 1 min...

Embodiment 2

[0074] 1) Filter 500ml of sugarcane juice with a 200-mesh filter cloth, control the pH to 4 with dilute hydrochloric acid; hydrolyze at 45°C for 2.5 hours, at a voltage of 11V, and a current density of 0.05A / cm 2 Remove impurities in the electrolytic cell for 7 hours, dilute and control the vitamin C content to 0.5 μg / 100g (measured by a fluorescence spectrophotometer), then filter through a microfiltration ceramic membrane with a membrane pore size of 50nm for 22 hours, dissolve in 1000ml methanol and stir evenly to obtain a mixed solution A ;

[0075] 2) Add 450 g of 0.07 mol / L copper salt solution, add 11 g of PVP, stir evenly, heat to 55°C, adjust the pH to 8 with ammonia water to obtain the mixed solution B;

[0076] 3) Add diethylene glycol monomethyl ether to mixed solution A and mixed solution B under a 700W ultrasonic field, according to the volume ratio of mixed solution A, mixed solution B and diethylene glycol monomethyl ether 3:6:1 Mix and stir for 1 minute to ob...

Embodiment 3

[0082] 1) Filter 500ml of sugarcane juice with a 220-mesh filter cloth, control the pH to 5 with dilute hydrochloric acid; hydrolyze at 55°C for 2 hours, at a voltage of 12V, and a current density of 0.06A / cm 2 Remove impurities in the electrolytic cell for 6 hours, dilute and control the vitamin C content to 1 μg / 100g (measured by a fluorescence spectrophotometer), then filter through a microfiltration ceramic membrane with a membrane pore size of 50nm for 24 hours, dissolve in 1000ml methanol and stir evenly to obtain a mixed solution A;

[0083] 2) Add 500 g of 0.05 mol / L copper salt solution, add 14 g of PVP, stir evenly, heat to 60°C, adjust pH to 8 with ammonia water to obtain mixed solution B;

[0084] 3) Add diethylene glycol monomethyl ether to mixed solution A and mixed solution B under an 850W ultrasonic field, according to the volume ratio of mixed solution A, mixed solution B and diethylene glycol monomethyl ether 2.8:6.2:1.2 Mix and stir for 1 minute to obtain 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com