Flexible gear shaping comb

A toothed comb and flexible technology, which is applied in hair combs, clothing, hairdressing equipment, etc., can solve the problems of wooden comb structure inflexibility, thorny head, and hair pulling off, so as to relieve scalp irritation, reduce hair damage, and cushion pulling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

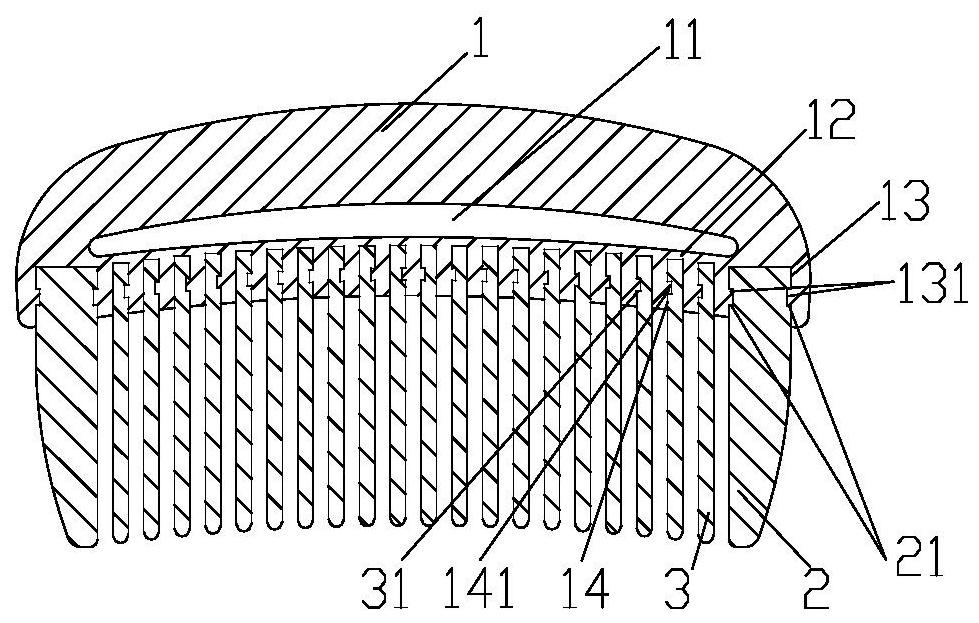

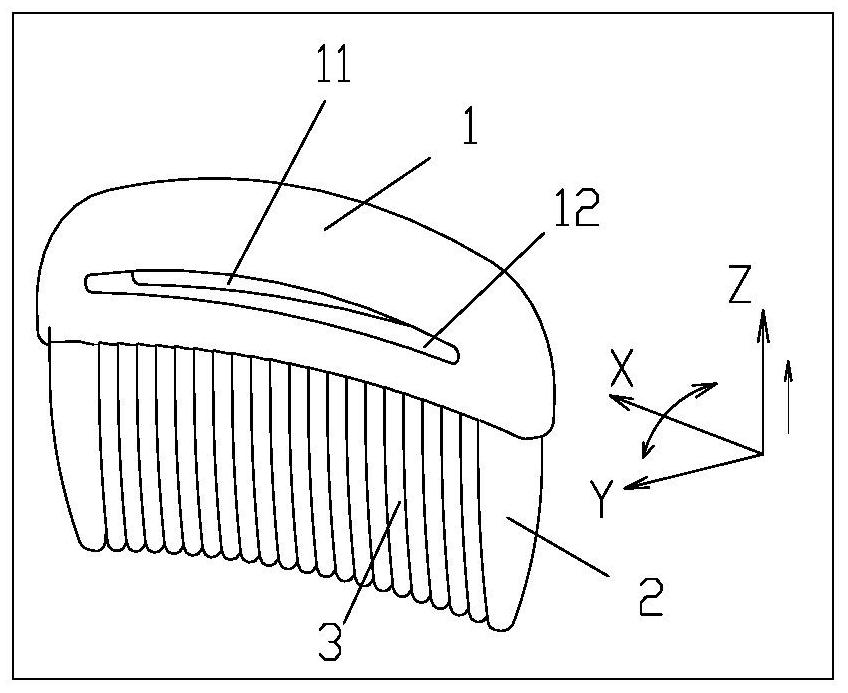

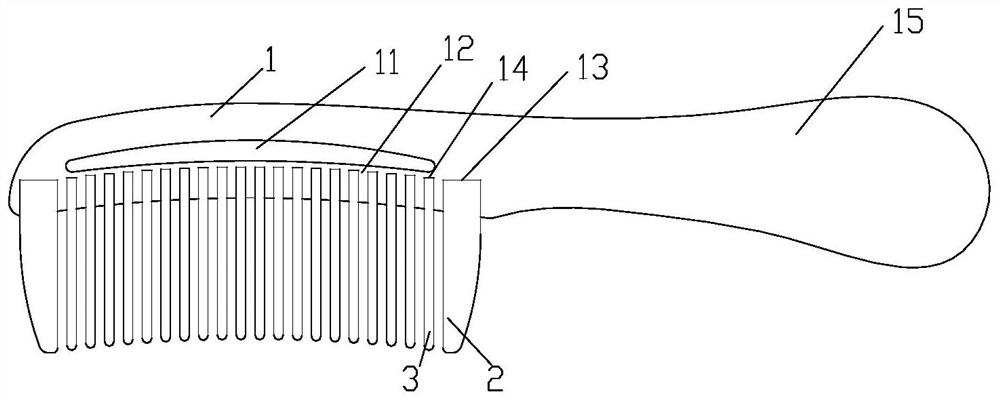

[0020] figure 1 It is a schematic cross-sectional structure diagram of the present invention; figure 2 is a perspective view of the present invention; image 3 It is a schematic diagram of the structure with a comb handle. As shown in the figure, a flexible plunging comb of the present invention includes a comb back 1 and a fixed tooth part 12 arranged on the comb back 1 along the comb tooth direction for fixing and installing the comb teeth 3 and the auxiliary teeth 2. The tooth portion 12 is made of elastic material; unlike the traditional simple arrangement of comb teeth 3 and auxiliary teeth 2 in the tooth holes on the comb back 1, the flexible tooth-shaping comb of the present invention is provided with fixed teeth on the comb back 1 alone. part 12, the fixed tooth part 12 is provided with tooth holes for installing comb teeth 3 and auxiliary teeth 2. The fixed tooth part 12 is made of elastic material, and the material of the comb back 1 and the fixed tooth part 12 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com