A multi-degree-of-freedom circuit board CNC machining machine tool

A technology for CNC machining machine tools and circuit boards, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems that circuit boards cannot be processed at the same time, and achieve convenient installation and connection, high degree of automation, The effect of rapid processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

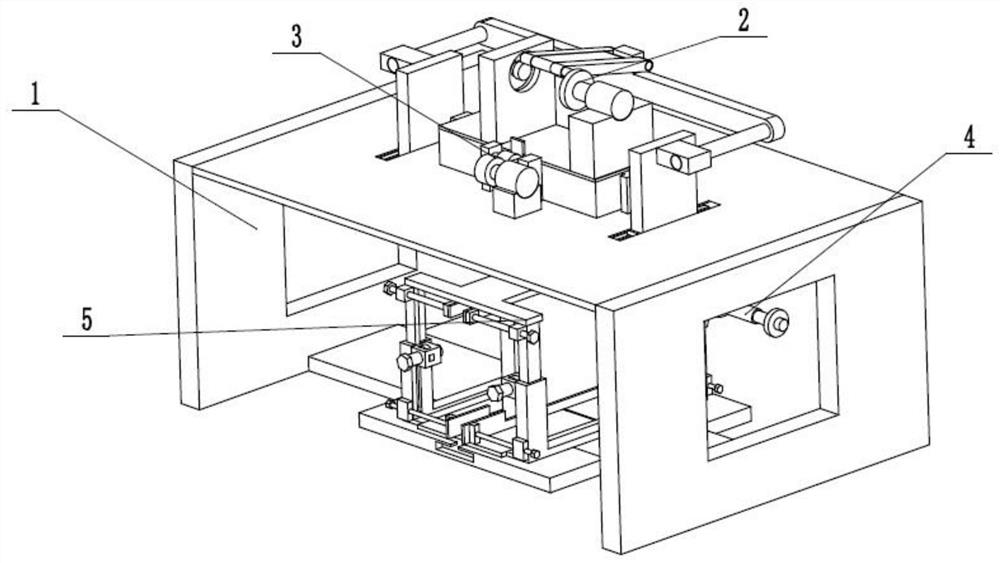

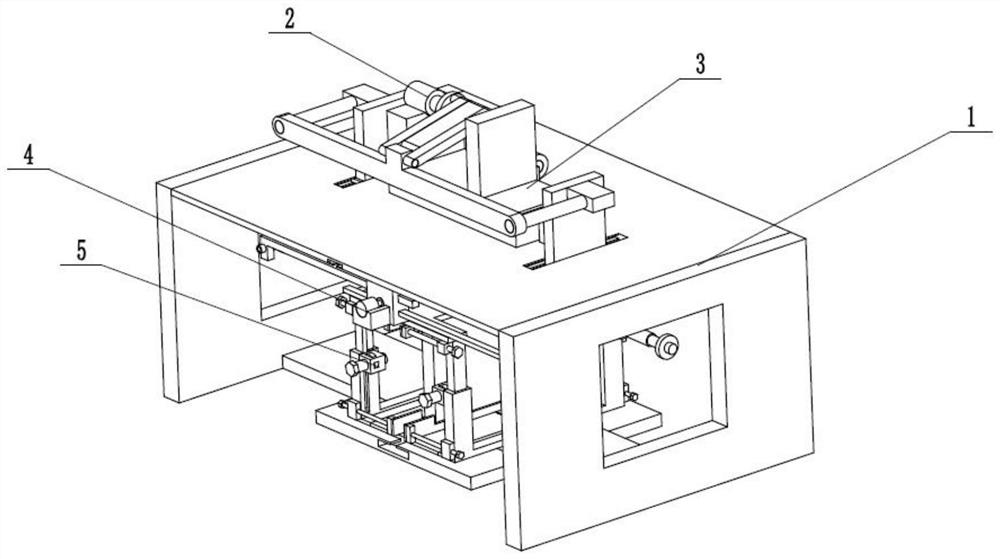

[0029] Such as Figure 1 to Figure 10 As shown, a multi-degree-of-freedom circuit board CNC processing machine tool includes a processing frame 1, a front and rear plane displacement driver 2, a longitudinal displacement driver 3, a symmetrical circuit board wiring groove processor 4 and a circuit board processing clamp 5, The front and rear planar displacement drivers are slidingly connected to the processing frame 1, the front and rear planar displacement drivers 2 are fixedly connected to the longitudinal displacement driver 3, and the longitudinal displacement driver 3 is longitudinally slidably connected to the processing frame 1, and the symmetrical circuit board wiring The two ends of the groove processor 4 are respectively connected to the front and rear plane displacement drivers 2 through the rotation of the sphere, the upper end of the symmetrical circuit board wiring groove processor 4 is slidably connected to the processing frame 1, and the circuit board processing...

specific Embodiment approach 2

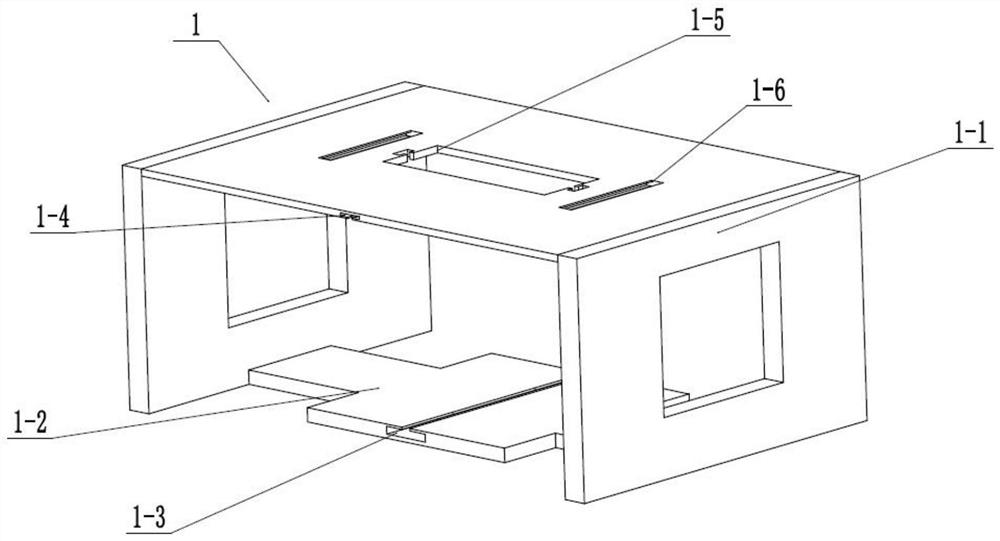

[0030] Such as Figure 1 to Figure 10 As shown, this embodiment will further illustrate Embodiment 1. The processing frame 1 includes a frame frame 1-1, a processing frame sliding bottom plate 1-2, a lower T-shaped chute 1-3, an upper T-shaped chute 1-4, the central longitudinal channel 1-5 and two slider chute 1-6, the sliding bottom plate 1-2 of the processing frame is fixedly connected to the lower end of the inner wall of the frame frame 1-1, and the lower T-shaped chute 1-3 The front and back are set on the sliding bottom plate 1-2 of the processing frame, the upper T-shaped chute 1-4 is set on the upper end of the inner wall of the frame frame 1-1, and the central longitudinal channel 1-5 is vertically penetrated and set on the frame frame 1-1 The upper end of the frame frame 1-1, two slide block chute 1-6 is evenly arranged on the upper end of the frame frame 1-1. The two ends of the frame frame 1-1 are respectively provided with two operation frames, which are conveni...

specific Embodiment approach 3

[0031] Such as Figure 1 to Figure 10 As shown, this embodiment will further explain the second embodiment. The front and rear plane displacement driver 2 includes a motor base 2-1, a front and rear translation drive servo motor 2-2, a drive turntable 2-3, and a drive slide bar 2-4. , limit turning slot 2-5, turning slot fixing seat 2-6, driving hinge plate 2-7, hinge seat 2-8, translation connecting rod 2-9 and two connecting sub-rods 2-10, front and rear translation drive servo The motor 2-2 is fixedly connected to the motor base 2-1, the drive turntable 2-3 is fixedly connected to the transmission shaft of the front and rear translation drive servo motor 2-2, and one end of the drive slide bar 2-4 is fixedly connected to the drive turntable 2- 3, the other end of the driving slide bar 2-4 is slidably connected in the limit turning groove 2-5, the limit turning groove 2-5 is arranged on the turning groove fixing seat 2-6, and the drive hinge plate 2-7 The two ends of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com