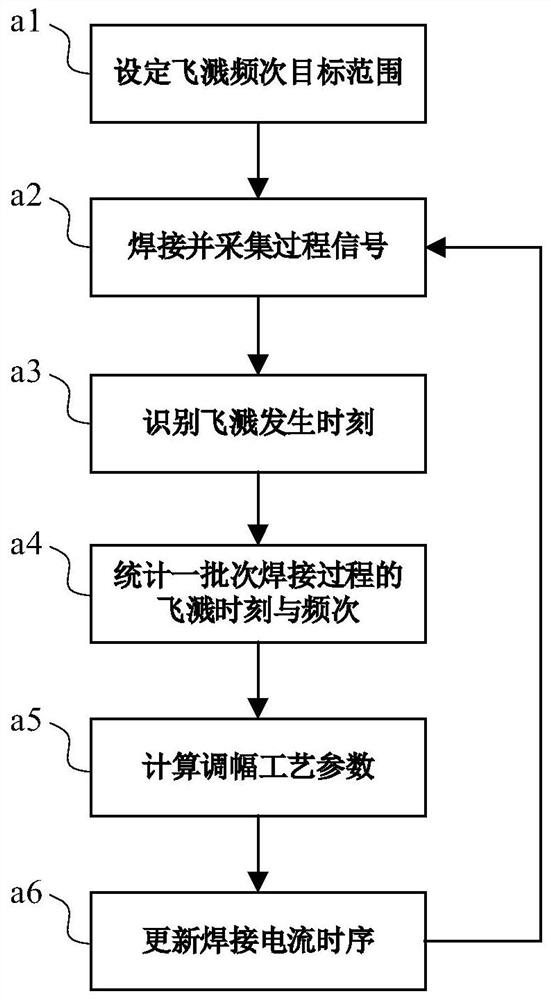

Resistance spot welding short-time amplitude modulation control method based on spatter statistical feedback

A technology of amplitude modulation control and resistance spot welding, applied in resistance welding equipment, manufacturing tools, welding equipment, etc., can solve problems such as self-adaptive adjustment of industrial parameters, large size deviation of stamping parts, and oily surface of workpieces, etc., to achieve high-efficiency resistance points Soldering process, reduce frequency, and ensure the effect of solder joint quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

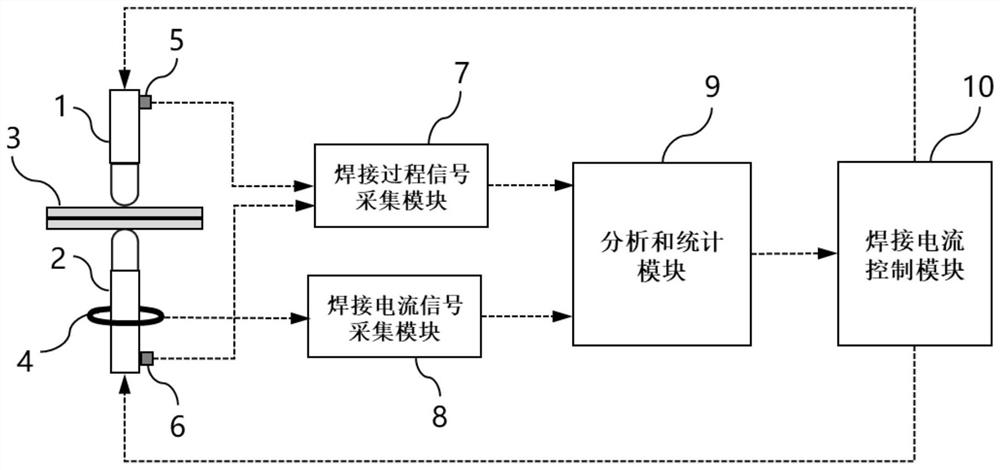

[0027] like figure 2 As shown, it is a short-term amplitude modulation control system for resistance spot welding based on spatter statistical feedback involved in this embodiment, including: a welding current control module 10, a calculation and analysis module 9 and a welding current signal acquisition module 8 respectively connected thereto And the welding process signal acquisition module 7, wherein: the welding current signal acquisition module 8 is connected with the current sensor 4 arranged on the lower electrode and collects the current signal, and the welding process signal acquisition module 7 is respectively connected with a pair of electrodes 1 and 2. The signal acquisition sensors 5 and 6 are connected to collect welding process signals, and the calculation and analysis module 9 performs identification and statistics of spatter conditions according to the welding process signals, forms optimized short-term amplitude modulation process parameters and outputs them ...

Embodiment 2

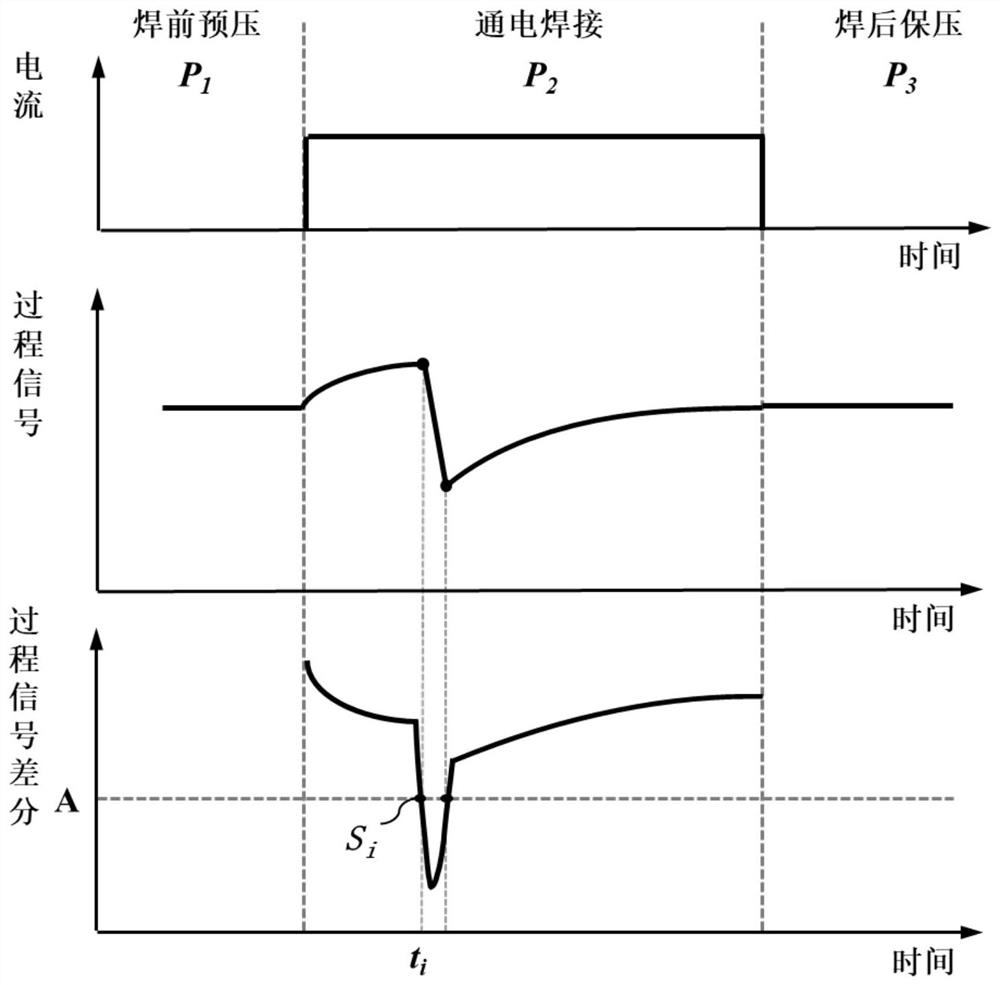

[0048] The difference from Embodiment 1 is that the welding process signal of this embodiment uses the electrode displacement signal, that is, the displacement signal of the electrode cap during the welding process is collected through the grating displacement sensors connected to the upper and lower electrode rods respectively, and the spot welding spatter identification and identification are carried out. Statistics, the preset threshold A is 8 μm / ms.

[0049] In this embodiment, the total number of solder joints in a batch of welding process is N=30 points, and the preset target range of spatter frequency is a=0, b=0.05; the statistical time of spatter occurrence is t s = m s -2σ s , where: the square average of the non-zero spatter occurrence time in a batch of welding process m s , and the standard deviation σ are: i represents the serial number of this welding process in a batch of welding process, 1≤i≤N, N is the total number of welding times of this batch of weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com