Bundling and packaging machine

A strapping and frame technology, which is applied to the parts of strapping machines, strapping objects, packaging/bundling objects, etc., can solve the problems of not detecting the strapping force of strapping balers, not detecting the success of strapping buckles, etc., to improve the packaging Efficiency, compact structure, and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

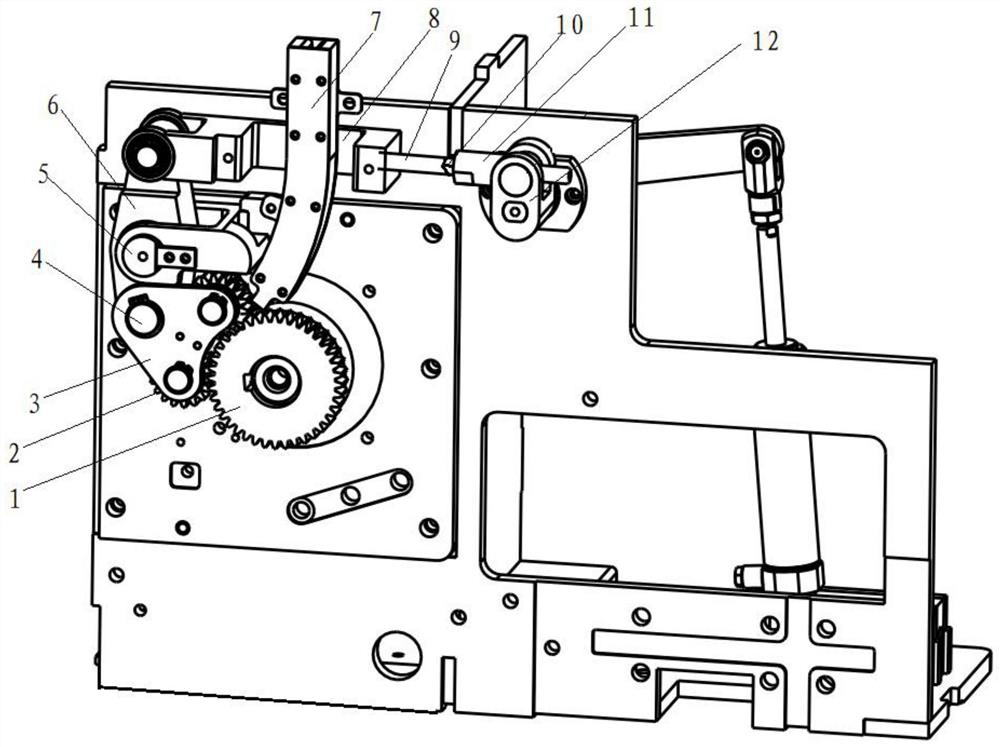

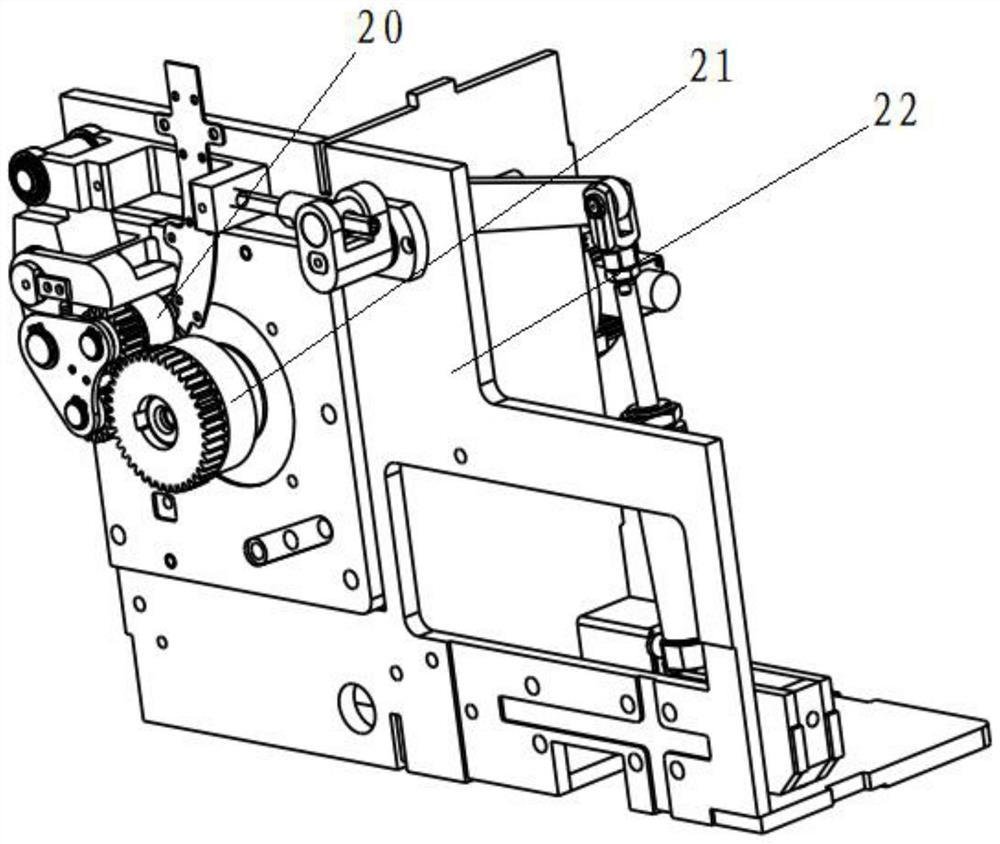

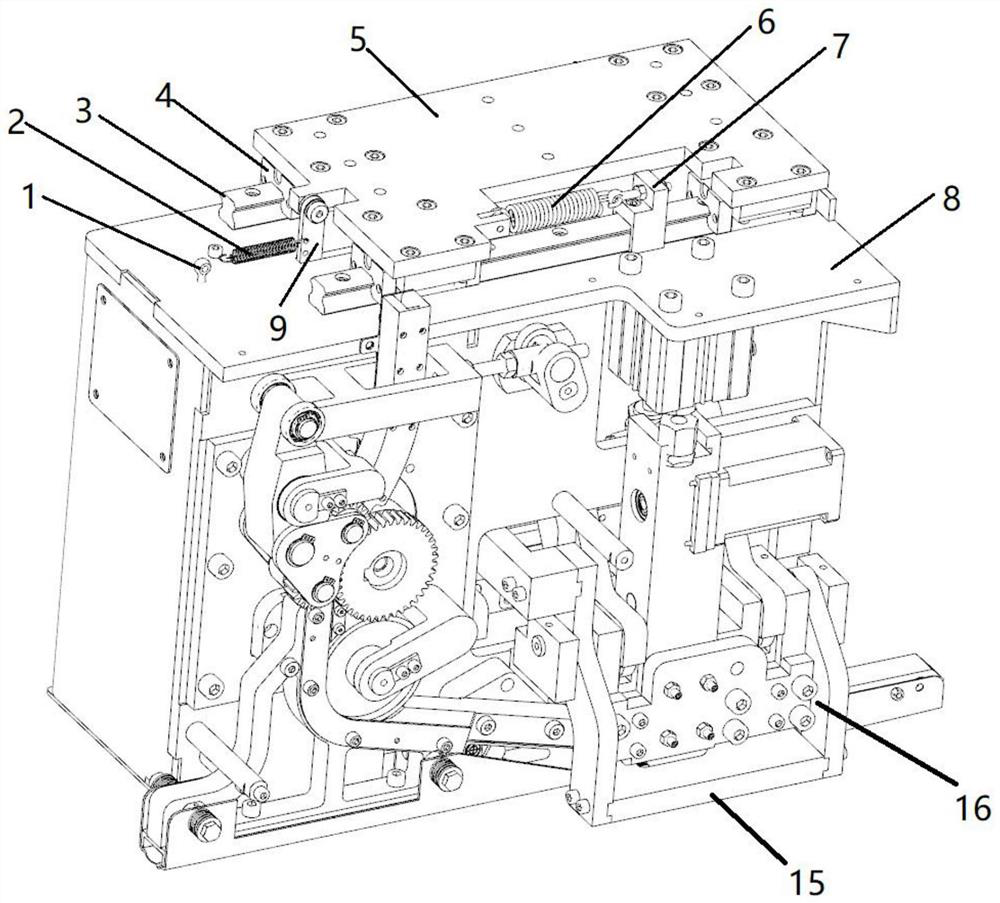

[0055] see Figure 3-12 As shown, the present invention relates to a strapping baler, which includes: a frame, a strapping force detection device, a buckle detection device and a cam device, and the frame is provided with a belt tensioning assembly, wherein,

[0056] The frame is used for installing a binding force detection device, a buckle detection device and a cam device;

[0057] The binding force detection device is used to detect the instant value of the tension of the binding belt and feed back the tension of the binding belt to the controller in time. By comparing the instant value of the binding tension with the required tension value of the binding article set by the controller, the controller controls The speed of the motor can provide different pressing forces to meet the bundling needs of different items;

[0058] The buckle detection device is used to detect whether the buckle is successfully tied, and feedback the detection result to the control system in time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com