TPO composition with light transmission characteristic and TPO artificial leather containing same

A technology of composition and artificial leather, applied in the direction of textiles and papermaking, synthetic resin layered products, vehicle parts, etc., can solve the problems of no analysis, no performance improvement of artificial leather, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

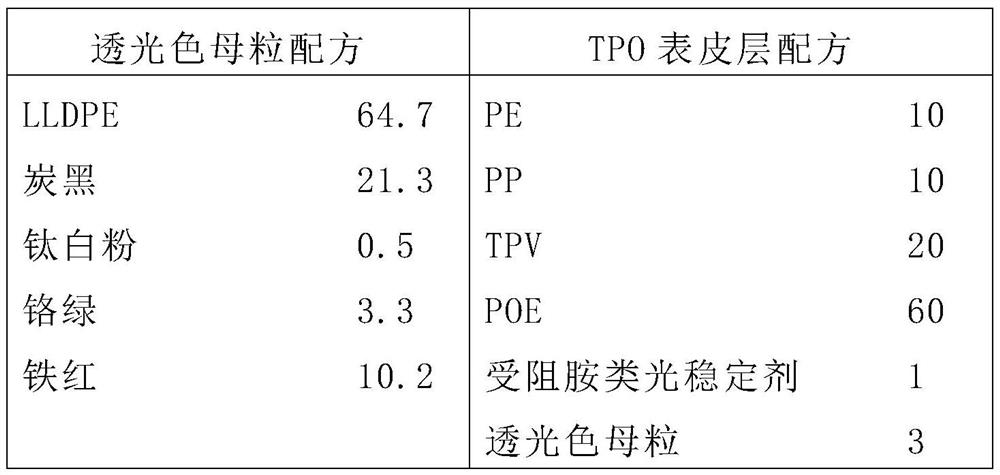

[0050] Prepare TPO artificial leather according to the following method:

[0051] In the first step, add the non-polar resin, main toner and auxiliary toner into the twin-screw extruder according to the translucent masterbatch formula in Table 1, extrude and cut to obtain the masterbatch;

[0052] In the second step, according to the TPO skin layer formula in table 1, polyolefin elastomer, polyolefin resin, rubber and the color masterbatch made by the first step are added in the twin-screw extruder in the form of composition, Heat and melt each component at 200°C and mix them evenly. Then the obtained mixture is extruded to prepare a TPO skin layer with a thickness of 0.5mm;

[0053] The third step is to evenly coat a layer of water-based polyurethane system paint with a thickness of about 0.2 μm on one side of the TPO skin layer by gravure printing to improve the feel, wear resistance and scratch resistance of the surface layer;

[0054] In the fourth step, the obtained TPO...

Embodiment 2

[0064] According to the formula of light-transmitting color masterbatch in Table 3 and the formula of TPO epidermis, adopt the same method as Example 1 to prepare TPO artificial leather, and adopt the same light transmittance detection method as in Example 1 to detect the light transmittance of TPO artificial leather , and the results of light transmittance are also shown in Table 3.

[0065] Table 3: TPO formulation (unit: parts by weight) and light transmittance of Example 2

[0066]

Embodiment 3

[0068] According to the formula of light-transmitting color masterbatch in Table 4 and the formula of TPO epidermis, adopt the same method as Example 1 to prepare TPO artificial leather, and adopt the same light transmittance detection method as in Example 1 to detect the light transmittance of TPO artificial leather , and the results of light transmittance are also shown in Table 4.

[0069] Table 4: TPO formulation (unit: parts by weight) and light transmittance of Example 3

[0070]

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com